Simulation test system and method for control program of cigarette sorting system

A sorting system and control program technology, which is applied in the field of computer simulation, can solve the problems of no simulation load test and insufficient control program test, and achieve the effects of reducing learning costs, improving test efficiency, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1: a simulation test system of the control program of the cigarette sorting system, comprising:

[0046] The simulation environment module is used to establish the simulation three-dimensional model of the sorting system equipment, and use the simulation program to write the operation mode of the sorting system equipment: vertical sorting machine, horizontal sorting machine, channel sorting machine, belt conveyor machine, cache conveyor, etc., and import the simulation environment for optimization and rendering, and develop the corresponding equipment 3D model unit for each equipment. The operation methods include: conveying, lifting, dialing, pushing, etc., and leave room for connection with the PLC controller The control output interface; and arrange the simulation detection devices, including: photoelectric switch, proximity switch, limit switch, encoder, etc. and leave the control program input interface connected to the PLC controller;

[0047]The order ...

Embodiment 2

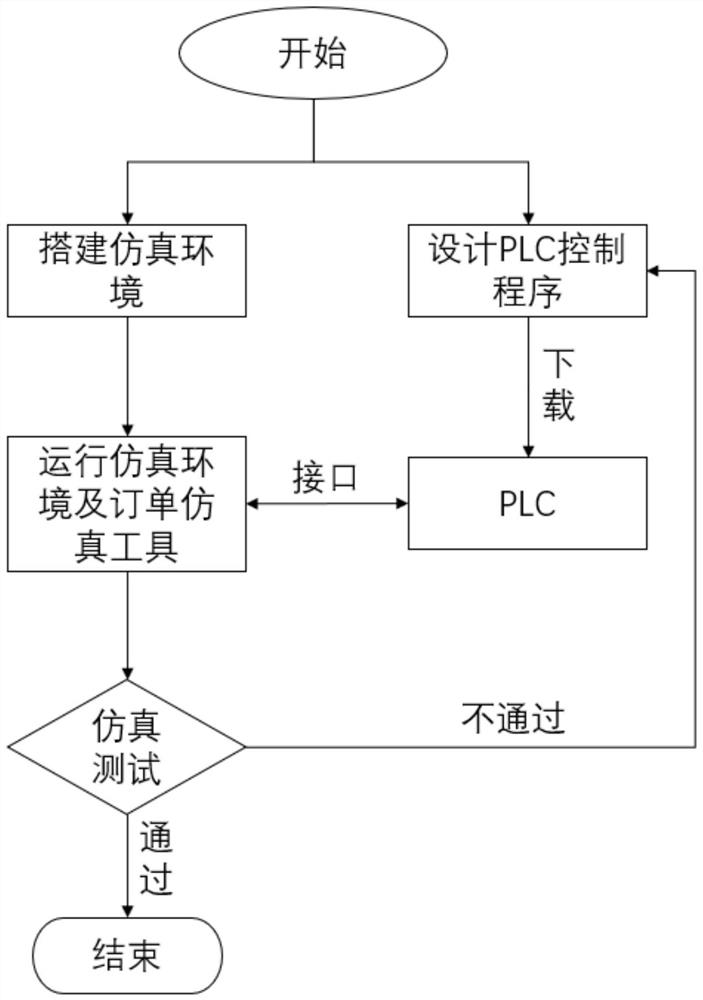

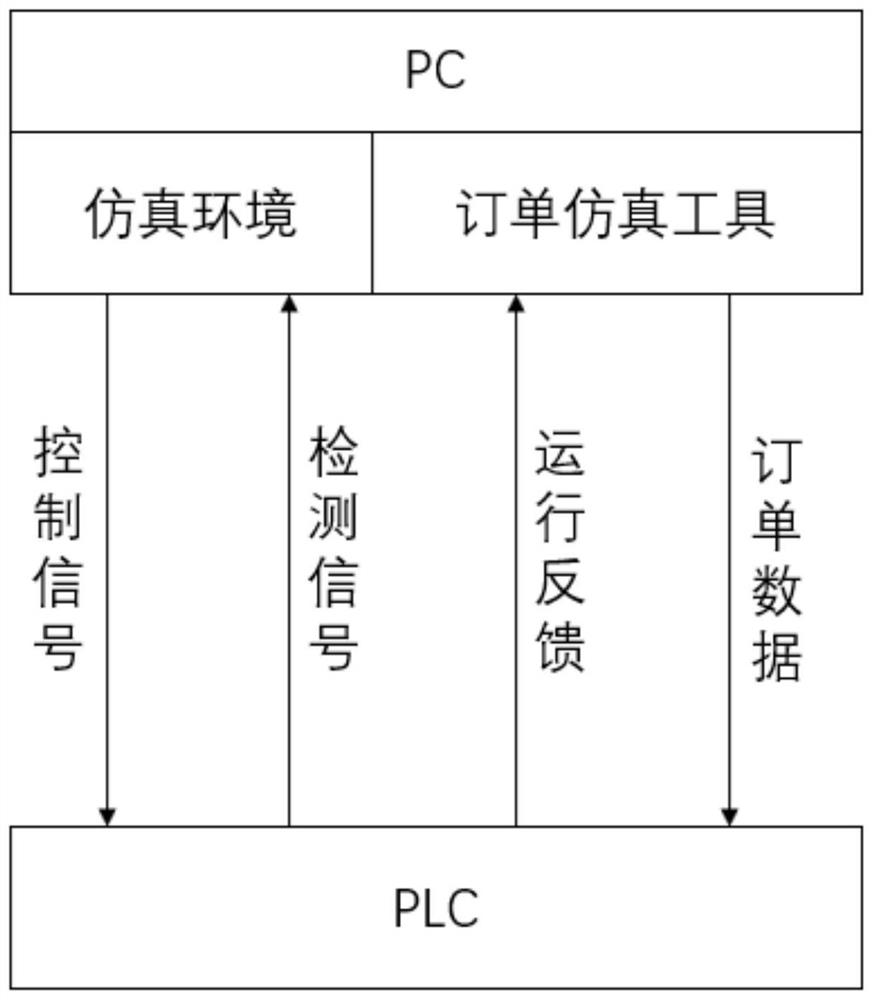

[0050] Such as figure 1 Shown is the simulation test method of the control program of the cigarette sorting system. First, the control program design can be started while the simulation environment is being built. After the design is completed, the control program is downloaded to the PLC; then the simulation environment and the order simulation tool are run. At this time, the PLC communicates with the simulation environment through the Ethernet for input and output chains. ; If the control program fails the test, it needs to be modified and re-tested until it passes. The simulation test device of the present invention comprises a simulation environment and an order simulation tool, which runs in a PC environment, and the object of the test is a control program, which runs in a PLC programmable logic controller. The relationship between the two is as follows: figure 2 shown. Specific steps are as follows:

[0051] Step 1: Prepare 3D model

[0052] Step 1-1: Use Demo3D to ...

Embodiment 3

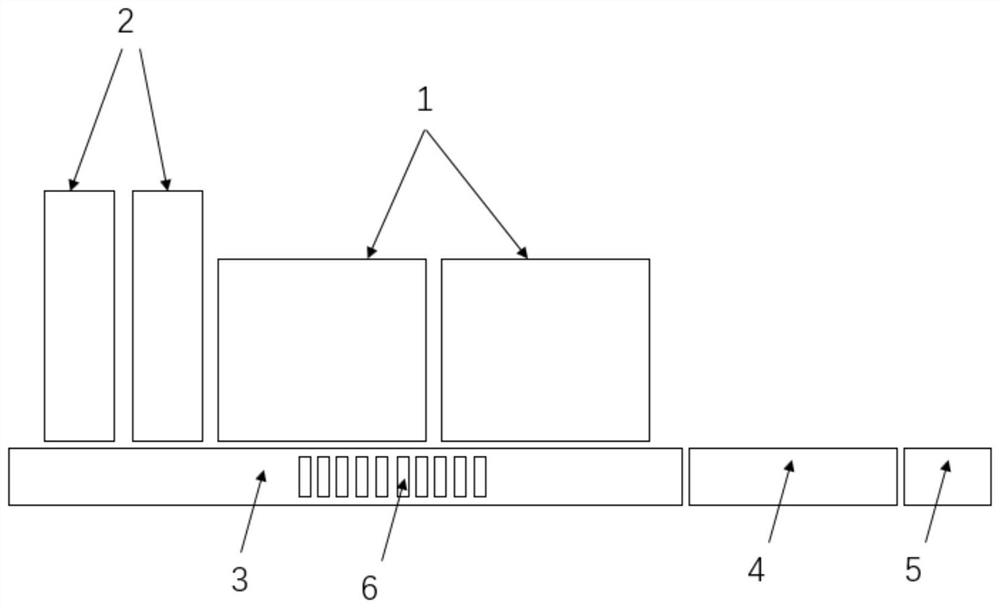

[0070] The sorting system equipment configuration of this test is as follows: image 3 As shown, it includes: 1 is the horizontal sorter, 2 is the channel sorter, 3 is the belt conveyor, 4 is the coding conveyor, 5 is the packing equipment, and 6 is the cigarette order. The actual function of the sorting system is to put cigarettes of different brands into the 1st horizontal sorter and 2nd channel sorter, dial them to the 3rd belt conveyor according to the order order, and transport the sticks to the 4th coding conveyor The cigarettes are coded, and finally enter the 5-packing equipment to pack the sorted cigarettes.

[0071] The requirements of the sorting system for the control program are: the posture of the dialed cigarettes is stable, the brand and quantity are consistent with the order, and on this basis, the sorting speed should be improved as much as possible. The speed of cigarette sorting is proportional to the dialing speed of the horizontal sorter and channel sort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com