High-quality full-color semiconductor light source

A semiconductor, high-quality technology, applied in the direction of semiconductor devices, electrical solid devices, electrical components, etc., can solve problems such as ineffective excitation of phosphors, low light efficiency of light sources, and decline in product performance, so as to solve the problem of phosphor deposition and improve optical performance. performance and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

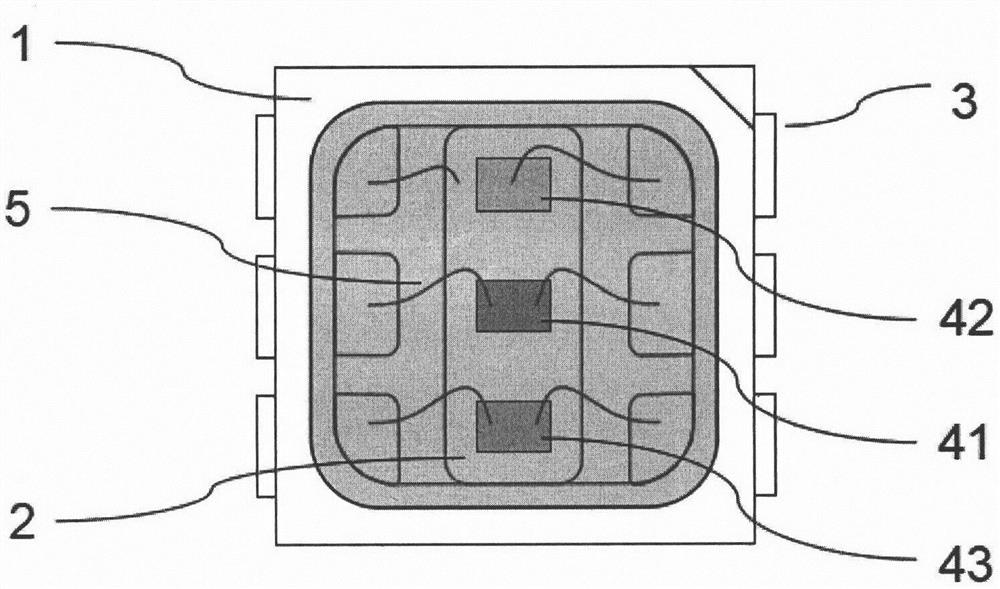

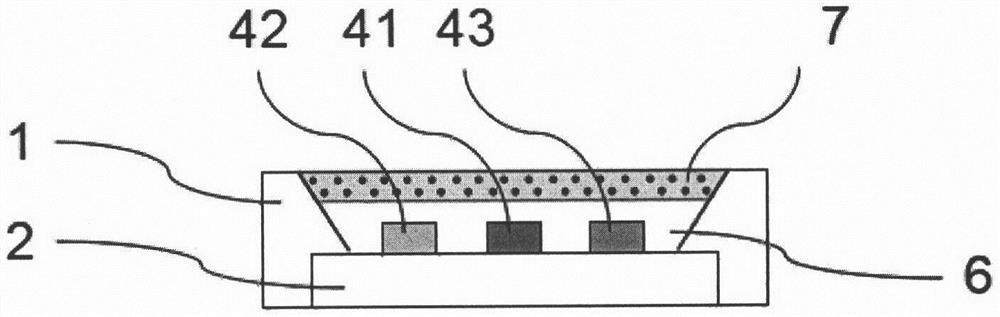

[0028] The structure of the selected semiconductor light source is a surface-mounted six-pin structure, such as figure 2 As shown, the main components of the light source include LED brackets, LED chips, packaging glue, etc., and the LED chips are selected from the red (R) chip 42 with the vertical structure, the green (G) chip 43 with the horizontal structure and the blue (B) chip with the horizontal structure. Chip 41, fix the three chips on the metal pad 2 of the LED bracket in the order of R-B-G or G-B-R, wherein the R chip is bonded with conductive paste, and the G and B chips are bonded with insulating paste. The wires 5 respectively electrically connect the positive and negative poles of the LED chip with the six pins 3 of the bracket.

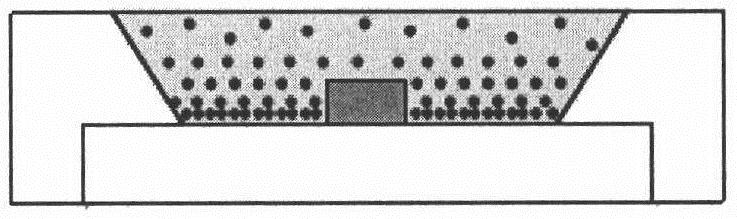

[0029] Mix and stir the two-component silicone resin A and B glue in proportion and defoam to obtain transparent packaging glue 6. Take a certain amount of transparent glue and add yellow phosphor with an excitation peak of about 570nm...

Embodiment 2

[0031] The implementation of the light source in this embodiment is based on the evolution of the embodiment 1. The difference from the embodiment 1 is that the R, G, and B chips all adopt a flip-chip structure, and the positive and negative electrodes of the chip and the standoff pins for electrical connections, such as Figure 4 As shown, at the same time, the red phosphor with the excitation peak of 630nm and the green phosphor with 530nm are selected as the phosphor powder. The rest of the implementation forms or processes are performed with reference to Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com