Two-stage hydraulic sorting device for kitchen garbage

A technology for kitchen waste and hydraulic separation, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of waste gas escape, increase the difficulty of waste gas treatment, increase labor cost and labor intensity of workers, and achieve easy The effect of maintenance and sorting process is short and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

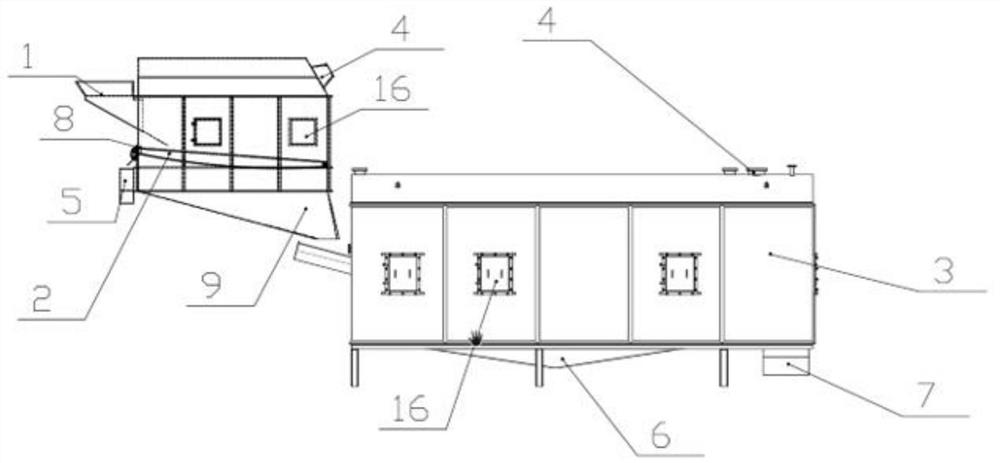

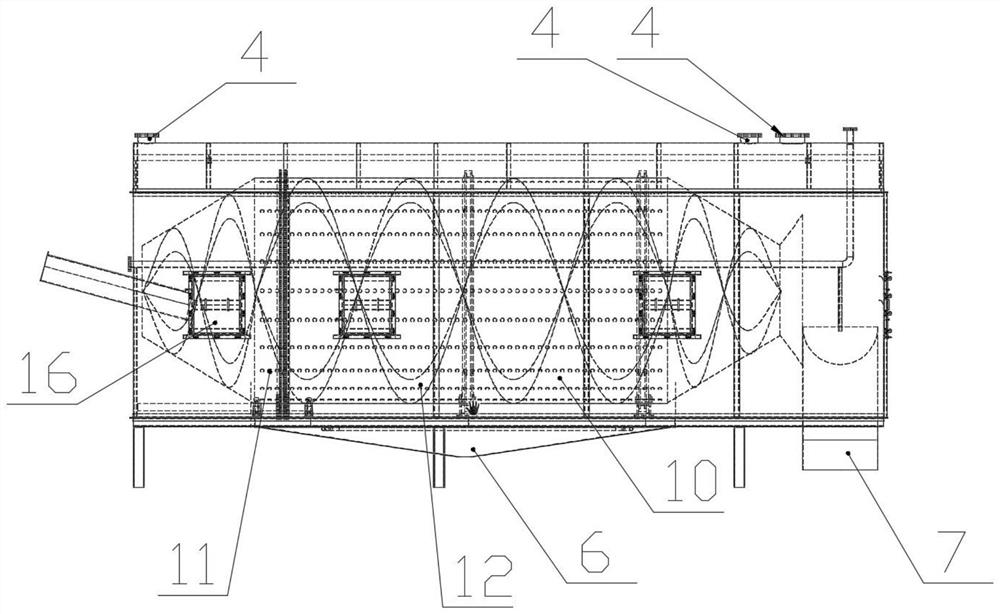

[0022] see Figure 1-Figure 3 As shown, this embodiment provides a secondary hydraulic separation device for kitchen waste, including a pretreatment module 2 and a water washing and separation module 3, the pretreatment module 2 is installed on the equipment platform, and the pretreatment module 2 includes a feed inlet 1 , the feeding port 1 is provided with a guide plate, and the equipment of the pretreatment module 2 is provided with a net-chain sorting device 8. The net-chain sorting device 8 is located below the feeding port 1, and the net-chain sorting device 8 There is a garbage collection tank 5 at the conveying end of the garbage collection tank. The garbage collection tank 5 is located outside the equipment of the pretreatment module 2. There is a flushing device in the garbage collection tank 5. The garbage collection tank 5 is connected to the bottom chute of the pretreatment module 2. The food waste collection and transportation vehicle can directly pour the waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com