Multi-nozzle reed leaf sorting and discharging device and using method

A sorting and unloading device, multi-nozzle technology, applied in sorting and other directions, can solve the problems of low degree of automation in the sorting of zongzi, affecting the production efficiency of zongzi, and high labor intensity, and achieve high-speed sorting and steering movement, increase The effect of reducing the number of pieces and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

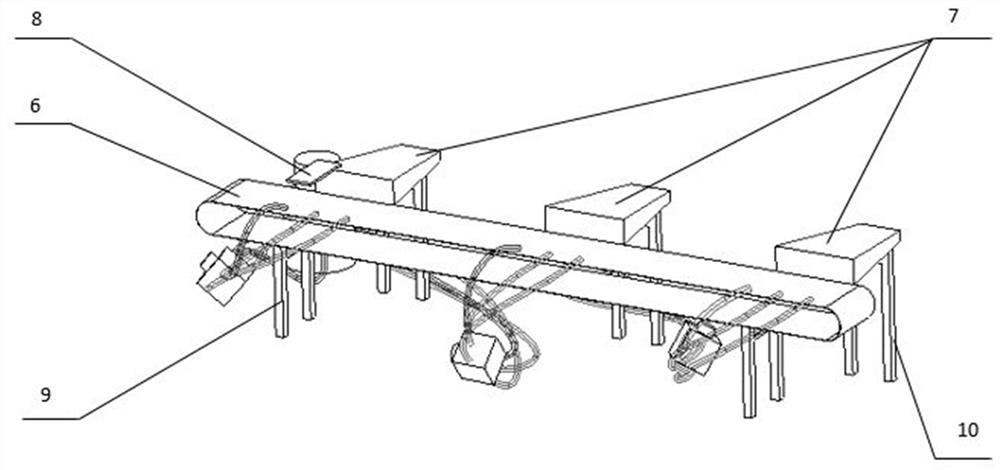

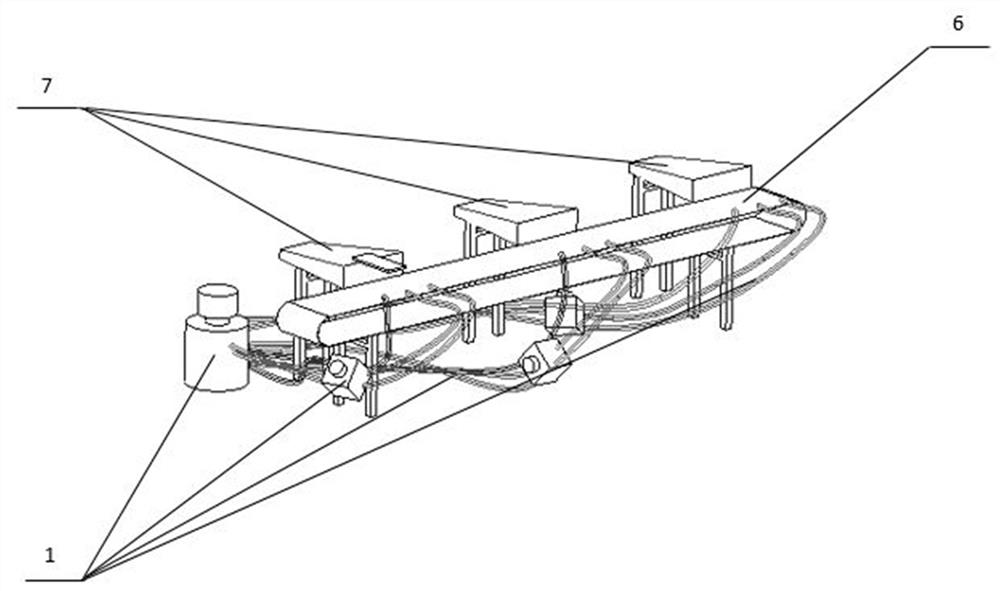

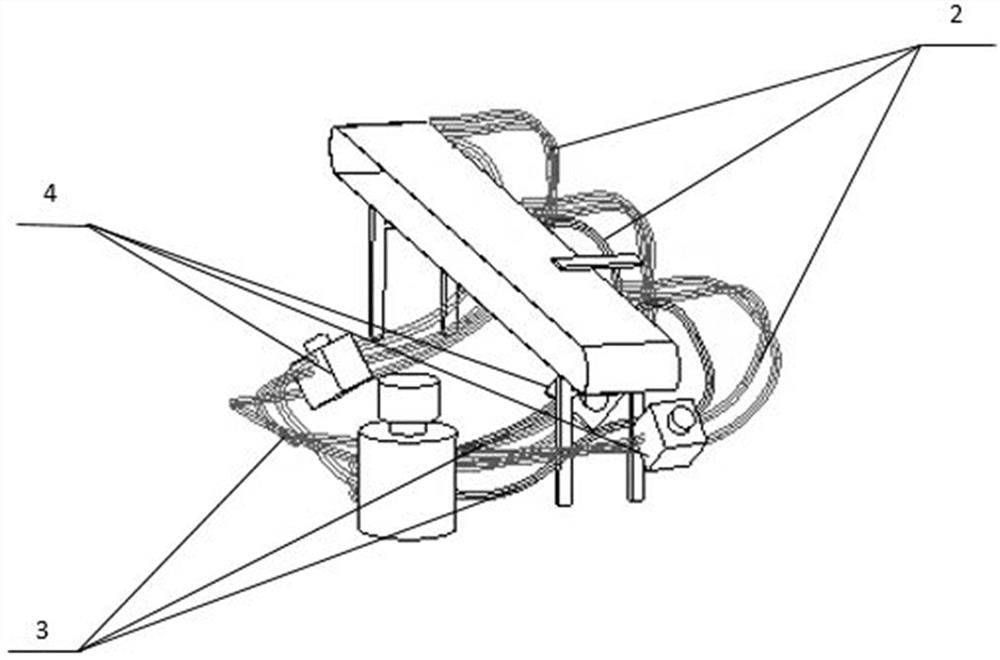

[0023] The preferred solution is as Figure 1 to Figure 4 Shown, a kind of multi-nozzle rice dumpling leaf sorting and blanking device and using method include air blowing device 1, and described air blowing device 1 includes many groups, and each group of air blowing device 1 includes a plurality of air outlet hoses 2. Each air outlet hose 2 corresponds to an air supply hose 3. Multiple sets of air outlet hoses 2 and air supply hoses 3 are connected together through the same valve 4. The other ends of the air supply hoses 3 are connected to the same air supply hose. The source 5 is connected; a plurality of outlet hoses 2 spouts of each group are fixed on one side of the feed conveyor belt 6, and a tapered connector is installed on the other side of the feed conveyor belt 6 facing the outlet hose 2 spouts. A feeding device 7 is provided with an inspection device 8 directly above the feeding conveyor belt 6 , and the feeding conveyor belt 6 and the tapered receiving device 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com