A sorting mechanism for vacuum adsorption sorting

A vacuum adsorption and vacuum technology, which is applied in the field of vacuum adsorption sorting material management mechanism, can solve the problems of easy multi-injection or under-injection, heavy workload, wrong material package delivery, etc., and achieve the effect of improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

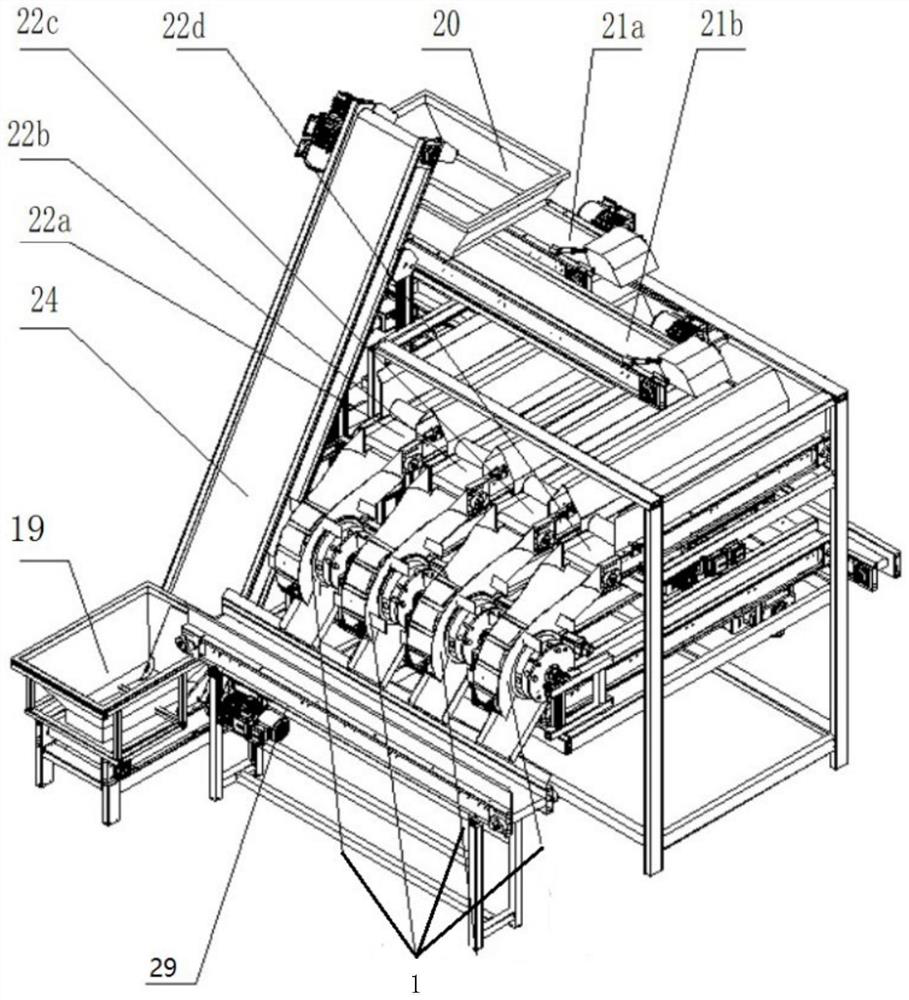

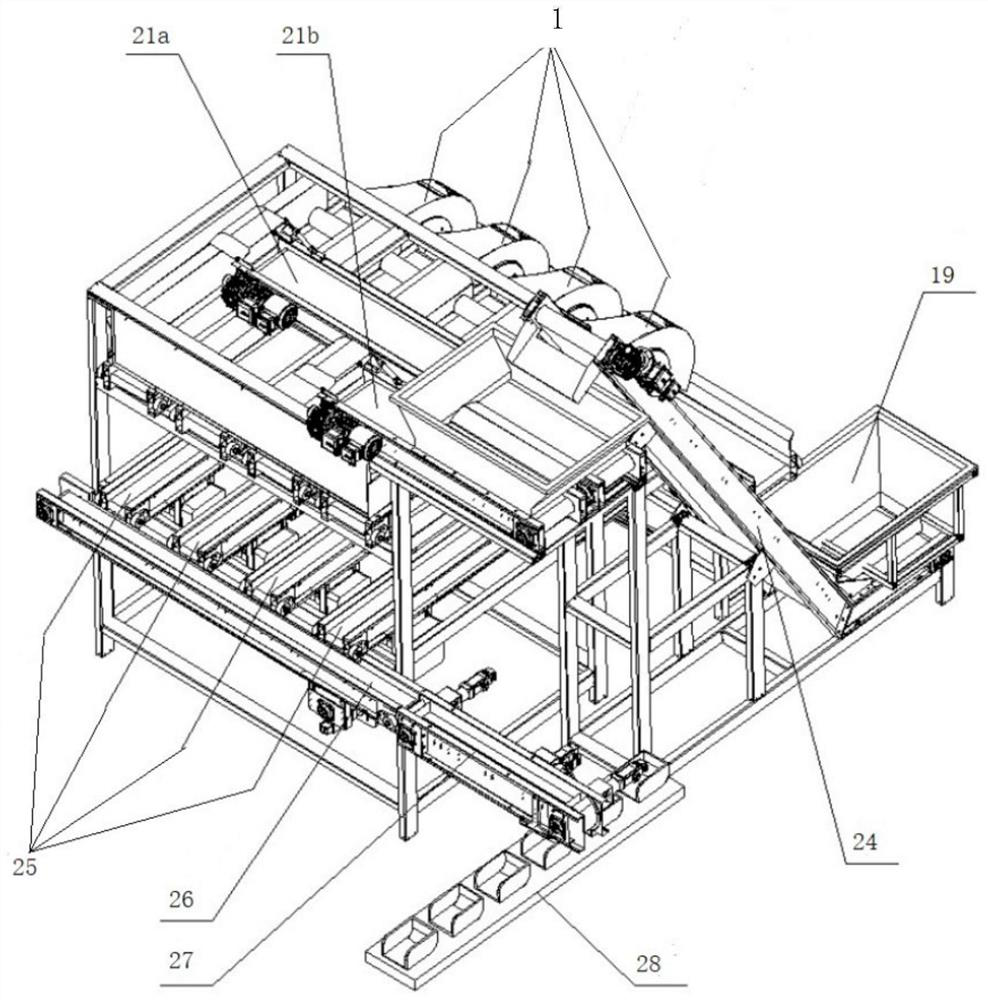

[0044] see Figure 6-15 It is a schematic diagram of the overall structure of a material arrangement mechanism for vacuum adsorption and sorting;

[0045] A material-arranging mechanism for vacuum adsorption and sorting includes: a rotating shaft 15 ;

[0046] The gas path splitter plate 2, the gas path splitter plate 2 is installed on the rotating shaft 15, and the gas path splitter plate 2 is closely attached to one end of the vacuum runner 1 on the rotating shaft 15;

[0047] The driving motor 5 is fixed on one side of the rotating shaft 15, and the output shaft of the driving motor 5 is parallel to the rotating shaft 15, and is used to drive the vacuum wheel 1 to rotate; the two ends of the rotating shaft 15 are mounted on the on the bearing housing 6. The bottom end of the bearing seat 6 is symmetrically fixed with threaded holes on both sides, which is convenient for fixing the bearing seat 6 on the external support frame. One end of the rotating shaft 15 is fixedly in...

Embodiment 2

[0066] see Figure 1-5 as well as Figure 16 , is a schematic diagram of the overall structure of a multi-station material quantitative sorting and fast material sorting device and a material sorting method. This embodiment has similarities with the above-mentioned Embodiment 1, and the similarities will not be described in this embodiment. The difference is:

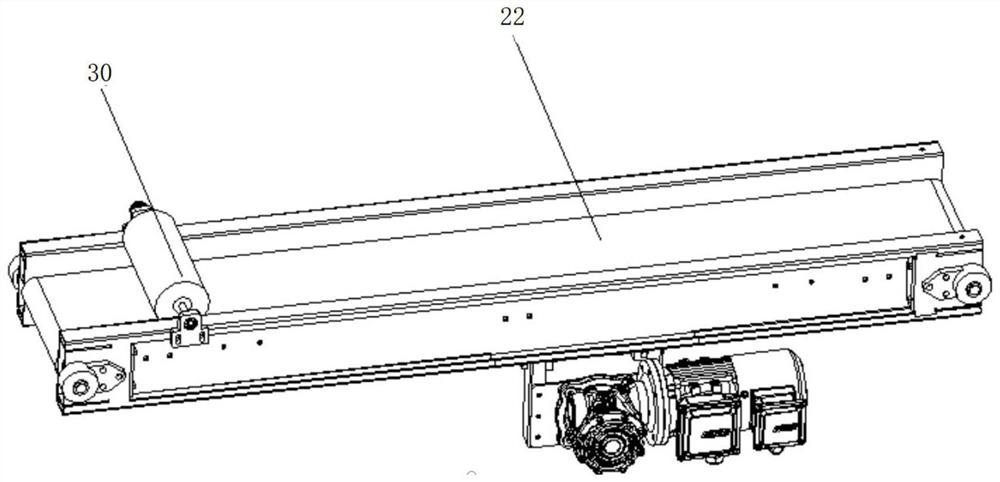

[0067]A multi-station material quantitative sorting and fast material sorting device includes an upper hopper 19, a plurality of material bags are stored in the upper hopper 19, and an upwardly inclined climbing belt 24 is fixed on the right side of the upper hopper 19. The climbing belt A top bin 20 is placed at the bottom of the 24. The top bin 20 is used to store the bales. The bottom end of the top bin 20 is fixedly installed with a plurality of material distribution belts 21. The adjacent two material distribution belts 21 are arranged in parallel. The end of the material distribution belt 21 is fixed with a mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com