Trajectory-controlled center-of-gravity adjustable polishing mechanism and polishing method

A trajectory control and polishing mechanism technology, which is applied in the direction of grinding/polishing equipment, manufacturing tools, optical surface grinders, etc., can solve the problems of inability to adjust the magnitude of the applied force, inability to solve online adjustments, etc., to reduce or eliminate the problem of edge effects , Strong practicability, simple control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

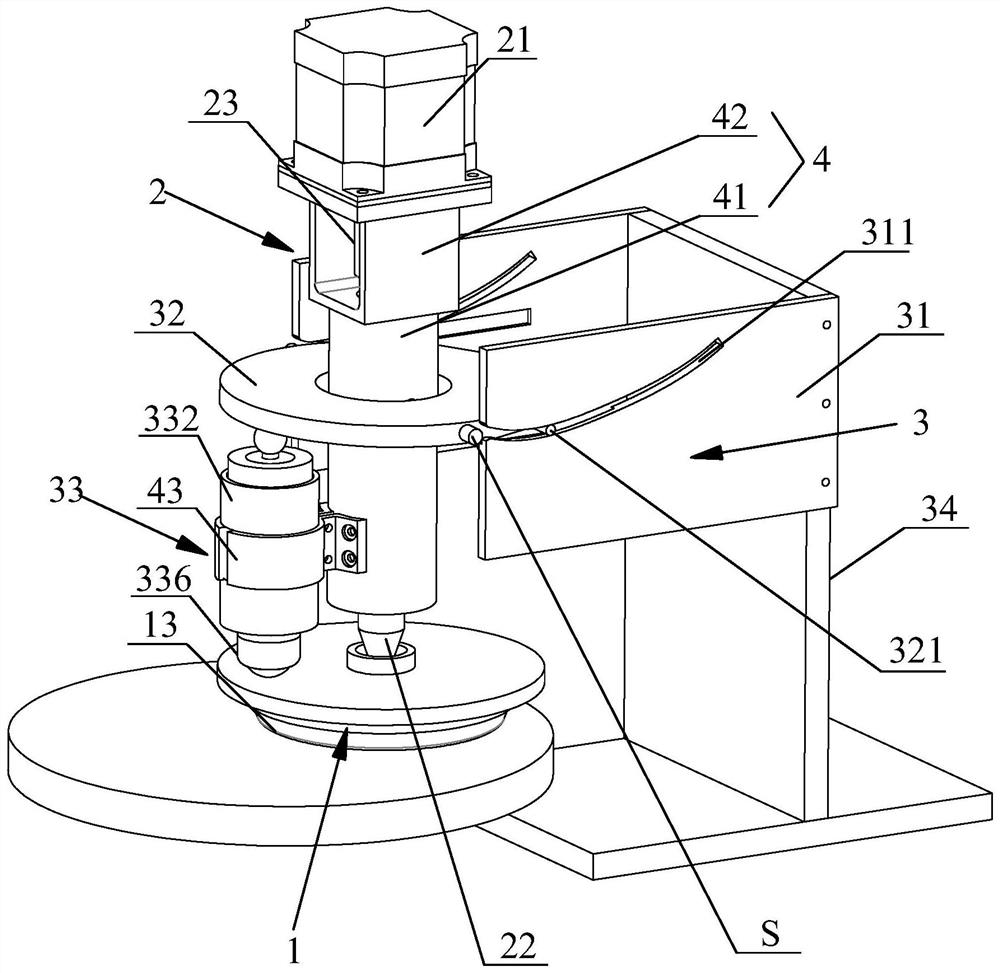

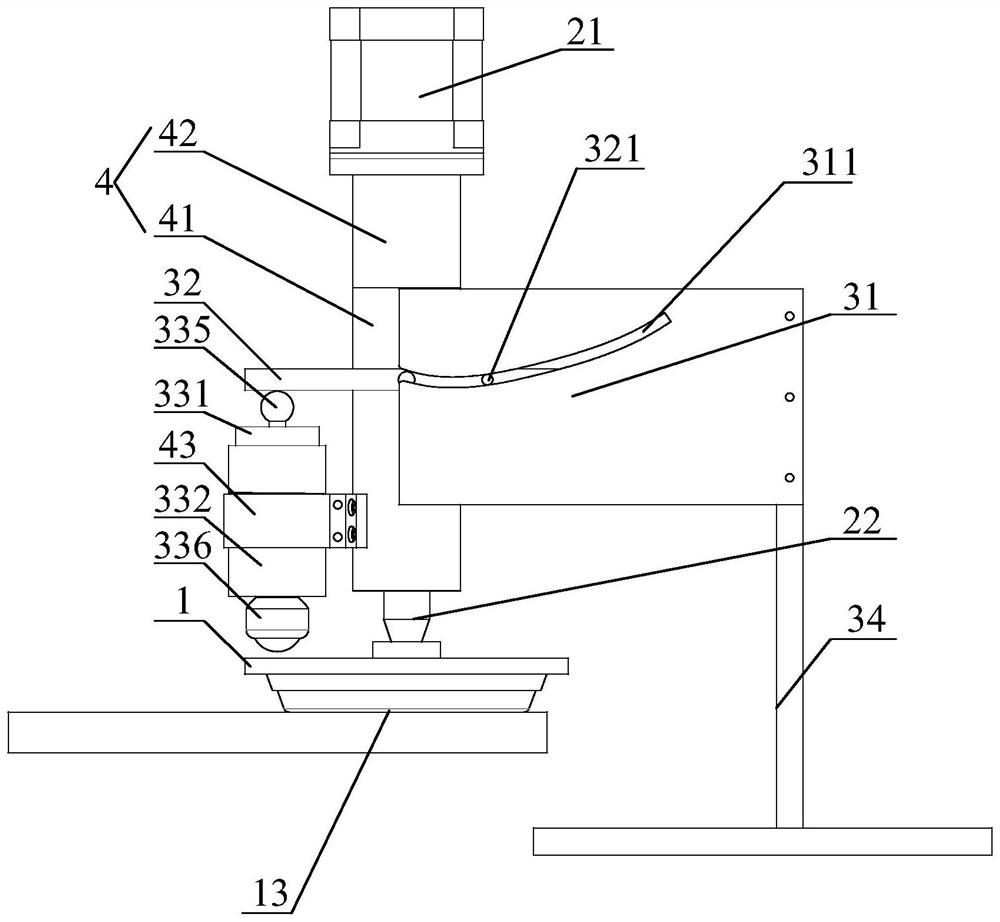

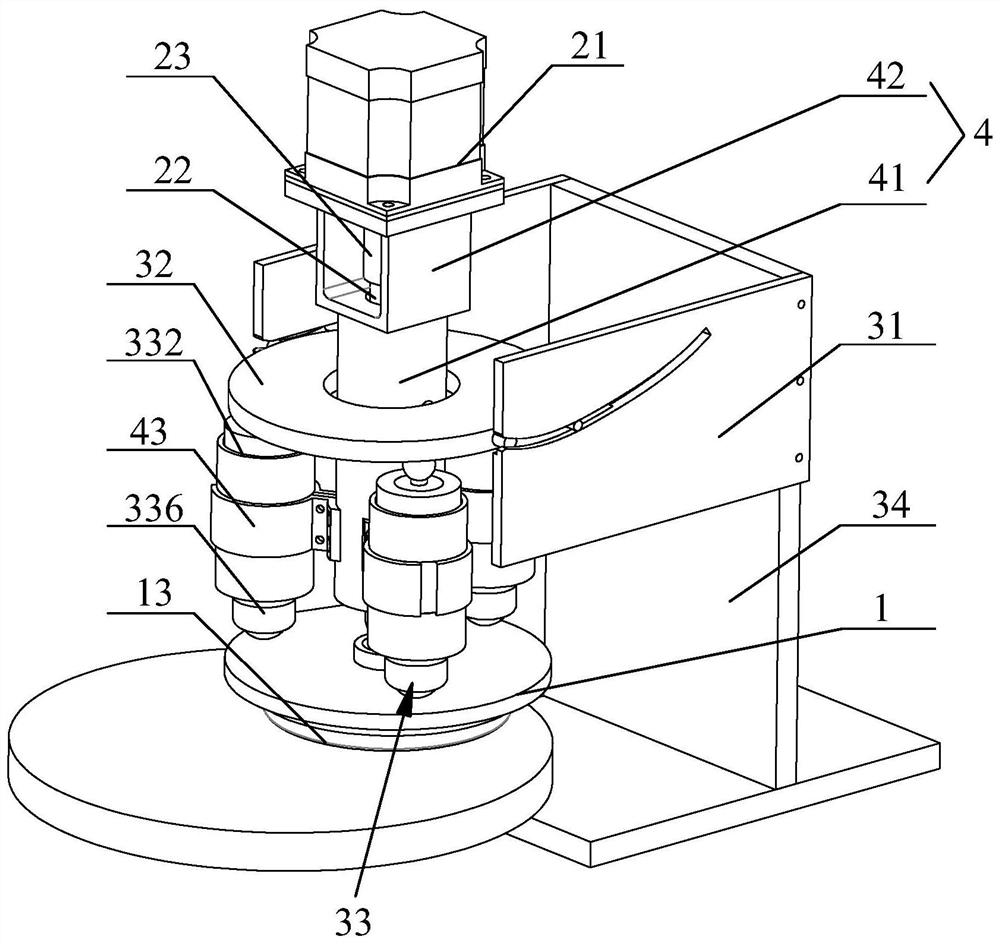

[0032] The invention discloses a trajectory-controlled adjustable center of gravity polishing mechanism, such as Figure 1-7 shown, is the preferred embodiment of the present invention. The polishing mechanism includes a polishing disc 1 , a power transmission mechanism 2 , a center of gravity adjustment mechanism 3 and a support mechanism 4 . in:

[0033] The polishing pad 13 may be provided at the bottom of the polishing disc 1. Specifically, the polishing pad 13 made of polyurethane or damping cloth may be attached to the bottom surface of the polishing disc 1 as a polishing working surface.

[0034] The power transmission mechanism 2 is used to transmit power to the polishing disc 1. The power transmission mechanism 2 at least includes a motor 21 and a power spindle 22. The lower end of the power spindle 22 is connected to the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com