Method for drilling T-shaped hole in furniture manufacturing plate

A board and drilling technology, applied in the direction of manufacturing tools, drilling machines, wood processing equipment, etc., can solve the problem of no professional drilling tools for inverted T-shaped holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

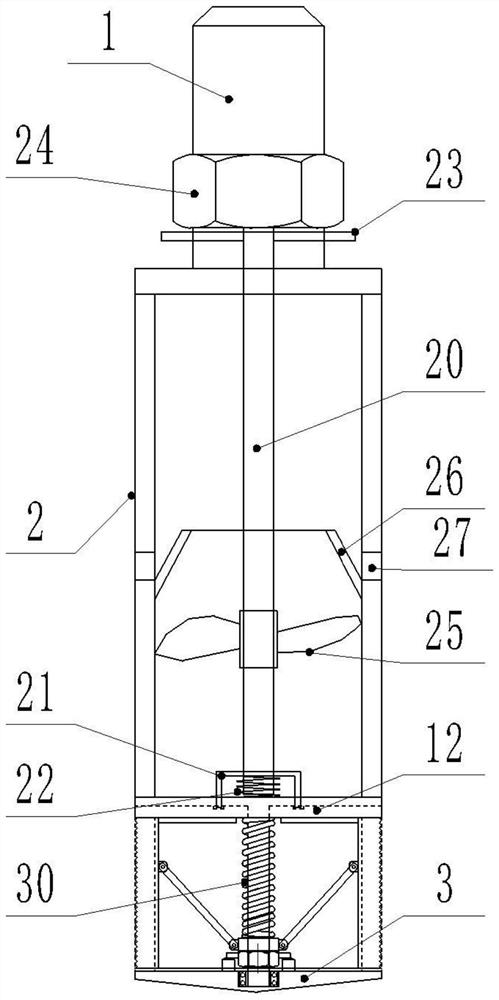

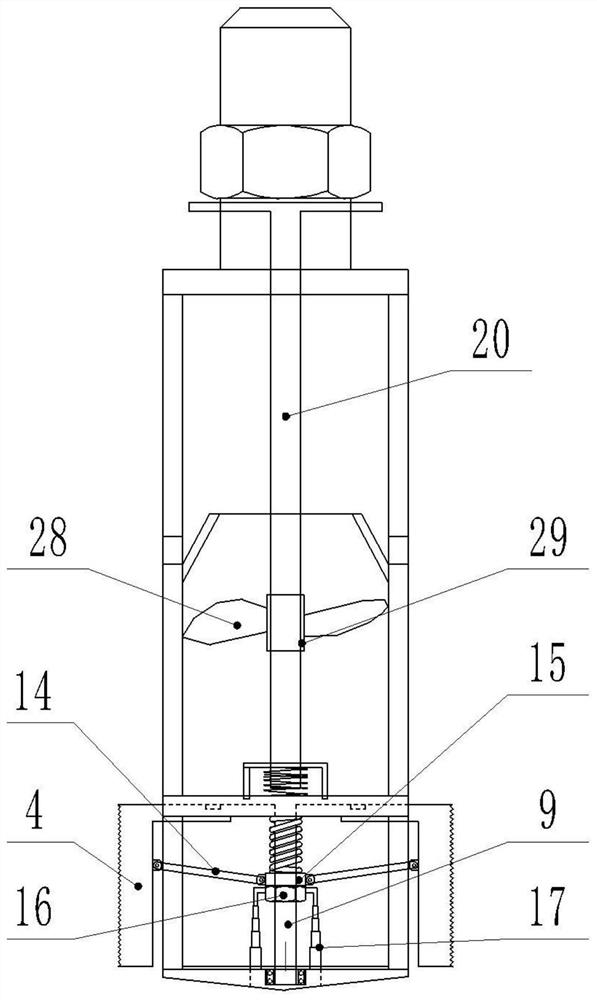

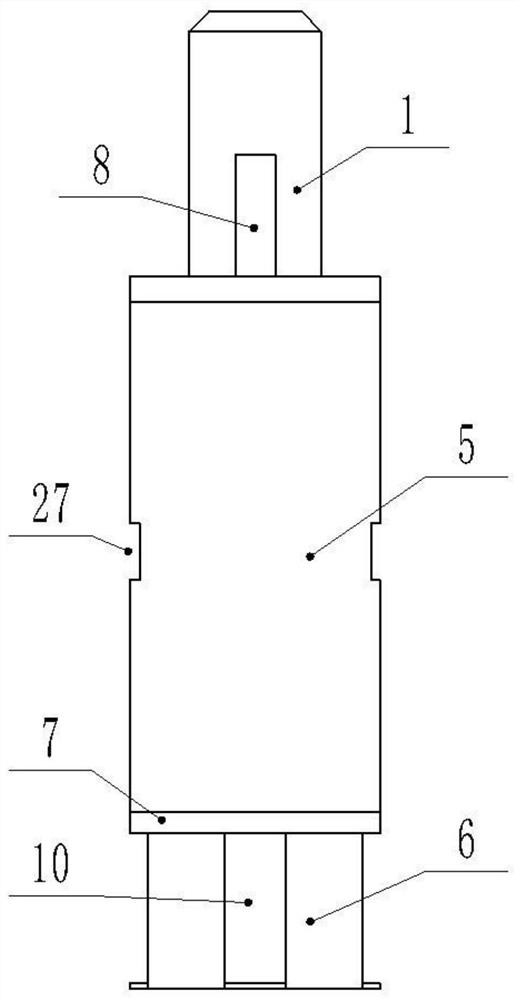

[0039] Such as Figure 1-10 Shown, a kind of method of the present invention drills T-shaped hole on the manufacture furniture plate, comprises steps:

[0040] Step 1, setting the drill tube body 1 includes an upper drill tube 5, a lower drill tube 6 and a drill tube connecting plate 7, the upper drill tube 5 and the lower drill tube 6 are connected by the drill tube connecting plate 7, and the upper end of the upper drill tube 5 is set There is a drill shank body 2, the middle part of the lower end of the drill shank body 2 is provided with an adjustment groove 8, and the inner axis position of the lower drill barrel 6 is provided with a guide connecting wire shaft 9 connected with the drill barrel connecting plate 7, and at the bottom of the lower drill barrel 6 The head is provided with a drill bit block 3, and the drill bit block 3 is connected to the guide connecting wire shaft 9 through a bearing;

[0041] Step 2. A plurality of milling cutter telescopic openings 10 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com