Pulp distribution device of rice straw decoration plate production line

A rice straw and production line technology, which is applied in cleaning devices, transportation and packaging, and pretreatment of molding materials, etc., can solve the problems of easy falling off, low strength, and poor use effect, so as to ensure cleanliness, facilitate long-term use, Avoid the effect of grout sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

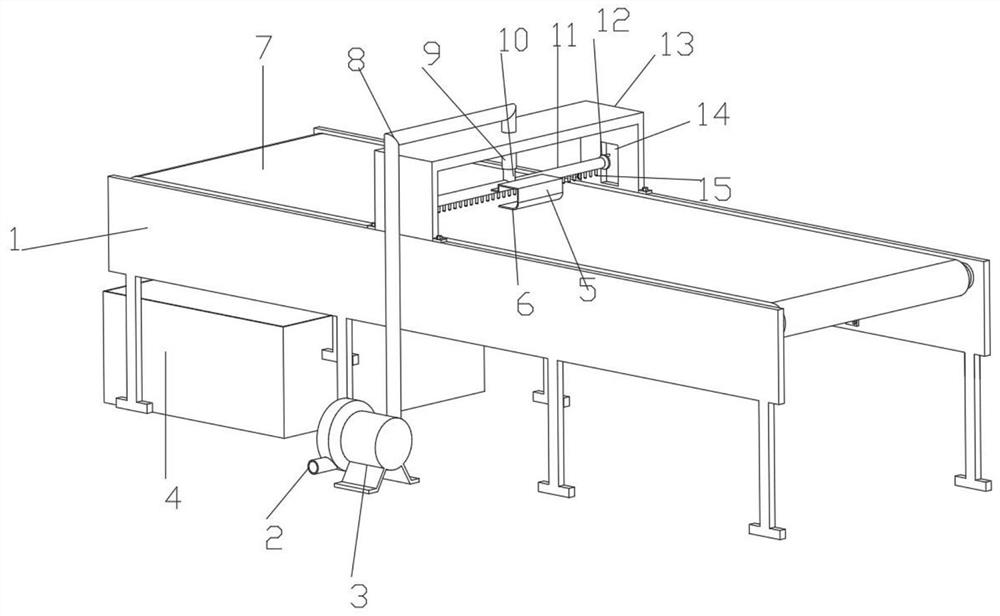

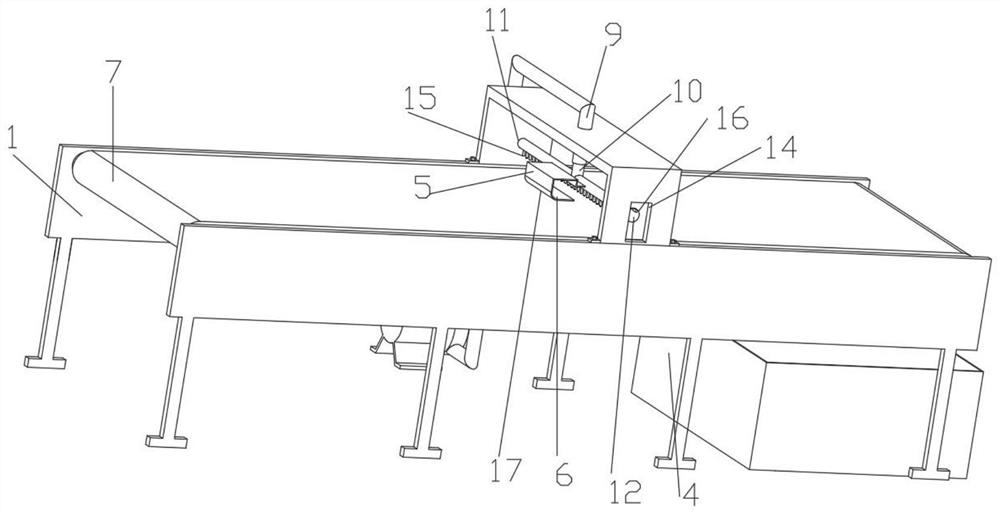

Embodiment 1

[0031] Such as figure 1 , 2 , 4, 6 shows a kind of paddy distributing equipment of rice straw decoration board production line, comprises support frame 1 and liquid pump 3, the inner wall of support frame 1 is evenly fixedly connected with bearing 20, the outer ring of bearing 20 and support frame 1 The inner wall is fixedly connected, and one set of rotating shafts 23 is not fixedly connected to the external drive motor. The inner ring of the bearing 20 is fixedly connected to the rotating shaft 23, and the rotating shafts 23 are fixedly connected to the transmission roller 18. The transmission roller 18 A conveyor belt 7 is movably connected, and the support frame 1 is connected with a dust-scraping structure for removing impurities on the surface of the conveyor belt 7. The top of the support frame 1 is fixedly connected with an n-shaped frame 13, and the top middle end of the n-shaped frame 13 is fixedly connected with a casing 9 , the top of the casing 9 is fixedly conne...

Embodiment 2

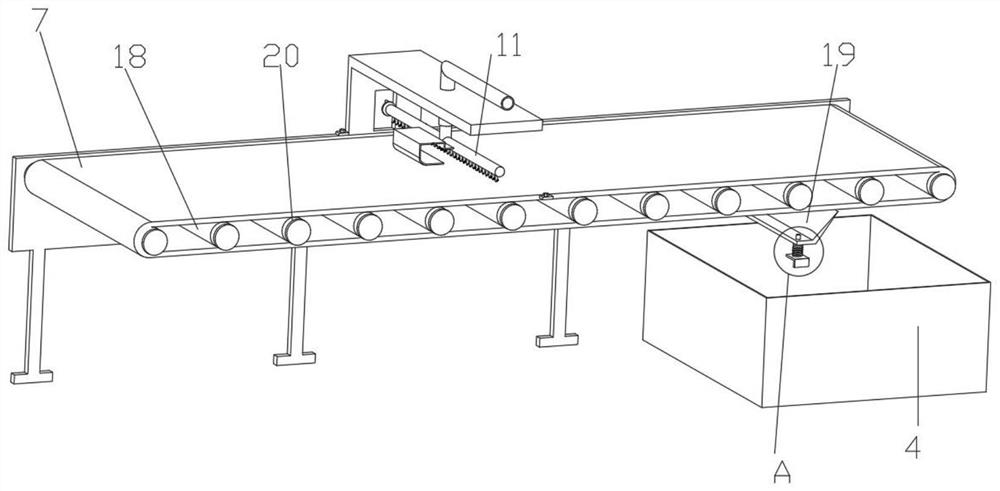

[0034] Embodiment 2 is a further improvement to Embodiment 1.

[0035] Such as figure 1 , 3As shown in , 5, a pulp distribution equipment for a rice straw decoration board production line includes a support frame 1 and a liquid pump 3, the inner wall of the support frame 1 is uniformly fixedly connected with a bearing 20, and the outer ring of the bearing 20 is fixed to the inner wall of the support frame 1 One set of rotating shafts 23 is fixedly connected with the external drive motor, the inner ring of the bearing 20 is fixedly connected with the rotating shaft 23, and the transmission roller 18 is fixedly connected between the rotating shafts 23, and the transmission roller 18 is flexibly connected There is a conveyor belt 7, and the support frame 1 is connected with a dust-scraping structure for removing impurities on the surface of the conveyor belt 7. The dust-scraping structure includes a collection box 4, an inclined scraper 19, a slide bar 24, a horizontal plate 25,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com