Injection molding machine mold adjusting method based on pull rod position and torque control

A technology of torque control and injection molding machine, which is applied to mold adjustment of injection molding machines with torque control. Based on the field of tie rod position, it can solve the problems of increased difficulty in debugging for on-site debugging workers, long automatic mold adjustment time, and unstable debugging, etc., and achieves small errors, Improved simplicity and convenient mold adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

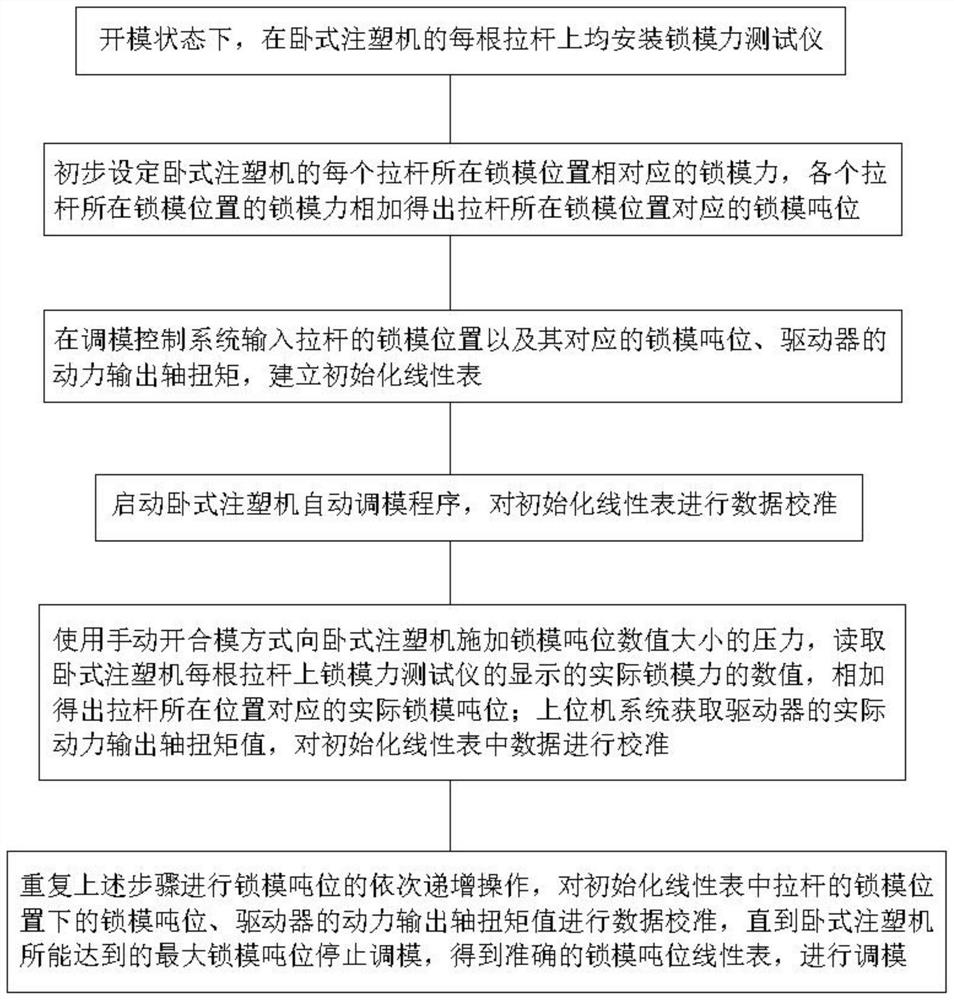

[0023] see figure 1 , a mold adjustment method for an injection molding machine based on tie rod position and torque control, comprising the following steps:

[0024] (1) In the state of mold opening, a clamping force tester is installed on each tie rod of the horizontal injection molding machine;

[0025] (2) Preliminarily set the mold clamping force corresponding to the mold clamping position of each tie rod of the horizontal injection molding machine, and add the mold clamping force at the mold clamping position of each tie rod to obtain the mold clamping tonnage corresponding to the mold clamping position of the tie rod;

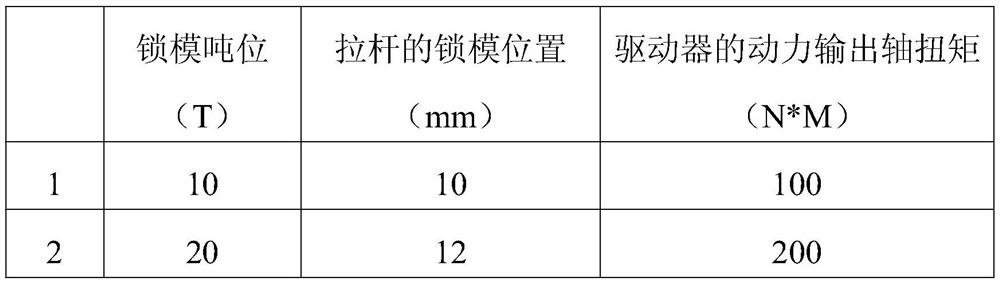

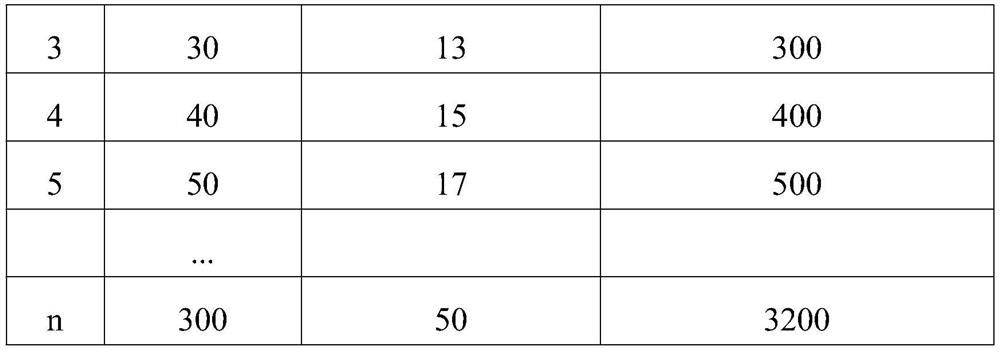

[0026] (3) Input the clamping position of the pull rod and its corresponding clamping tonnage and the torque of the power output shaft of the driver in the mold a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com