Placing rack based on glass production and using method thereof

A technology for placing racks and glass, applied in the directions of external frames, unloading devices, containers to prevent mechanical damage, etc., can solve the problems of unclassified placement, inconvenient glass plate picking and placement, increasing the workload of staff, etc., to achieve good collection and placement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

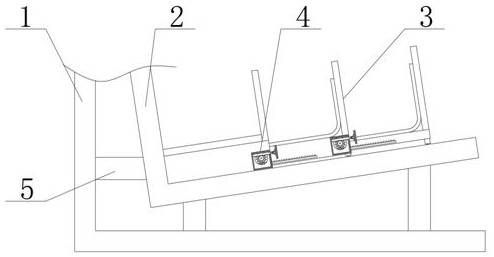

[0022] Example 1: See Figure 1-5 , the present invention provides a technical solution:

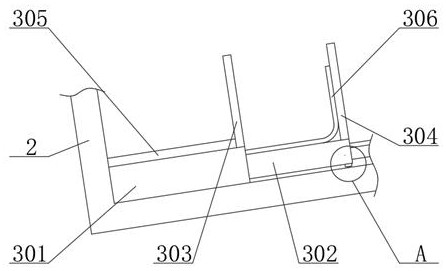

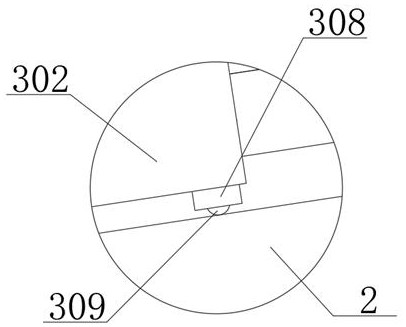

[0023] A placement frame based on glass production, comprising a right-angle base frame 1, an inclined base 2, a placement device 3 and an adjustment device 4, the top surface of the right-angle base frame 1 is provided with an inclined base 2, and the outside of the inclined base 2 is uniformly fixed and connected There is a connecting rod 5, and the other end of the connecting rod 5 is fixedly connected with the right-angle base frame 1, and the inboard of the inclined base 2 is equipped with a placement device 3, and the placement device 3 includes a first placement frame 301, a second placement frame 302, a first stop Plate 303, the second baffle plate 304, the first protective pad 305 and the second protective pad 306, the inboard of the inclined base 2 is equipped with a first placement frame 301, and the right side of the first placement frame 301 is provided with a second placeme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com