Microcrystalline glass, microcrystalline glass product and manufacturing method of microcrystalline glass product

A technology of glass-ceramics and products, applied in glass manufacturing equipment, manufacturing tools, glass tempering and other directions, can solve the problems of difficult to achieve mechanical properties and difficult chemical tempering.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0329] In order to further clearly illustrate and illustrate the technical solution of the present invention, the following non-limiting examples are provided. Efforts have been made to ensure accuracy with respect to values (eg, amounts, temperature, etc.) in the embodiments of the invention, but some errors and deviations must be accounted for. The composition itself is given in weight % based on oxides and has been normalized to 100%.

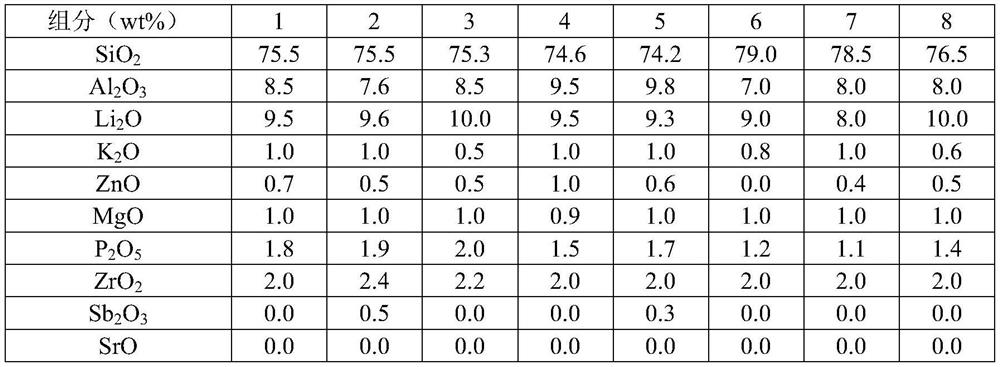

[0330] Shown in the following Tables 1 to 3 are examples of glass compositions

[0331] Table 1.

[0332]

[0333]

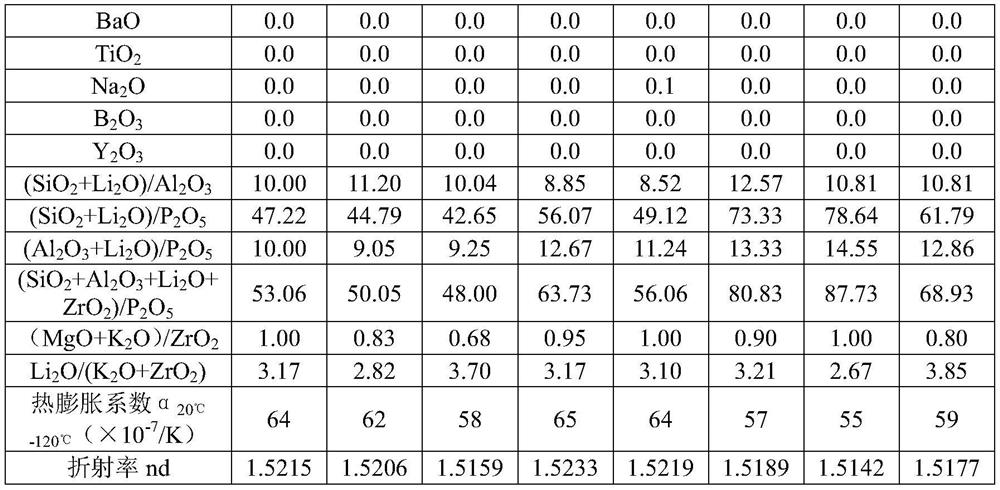

[0334] Table 2.

[0335]

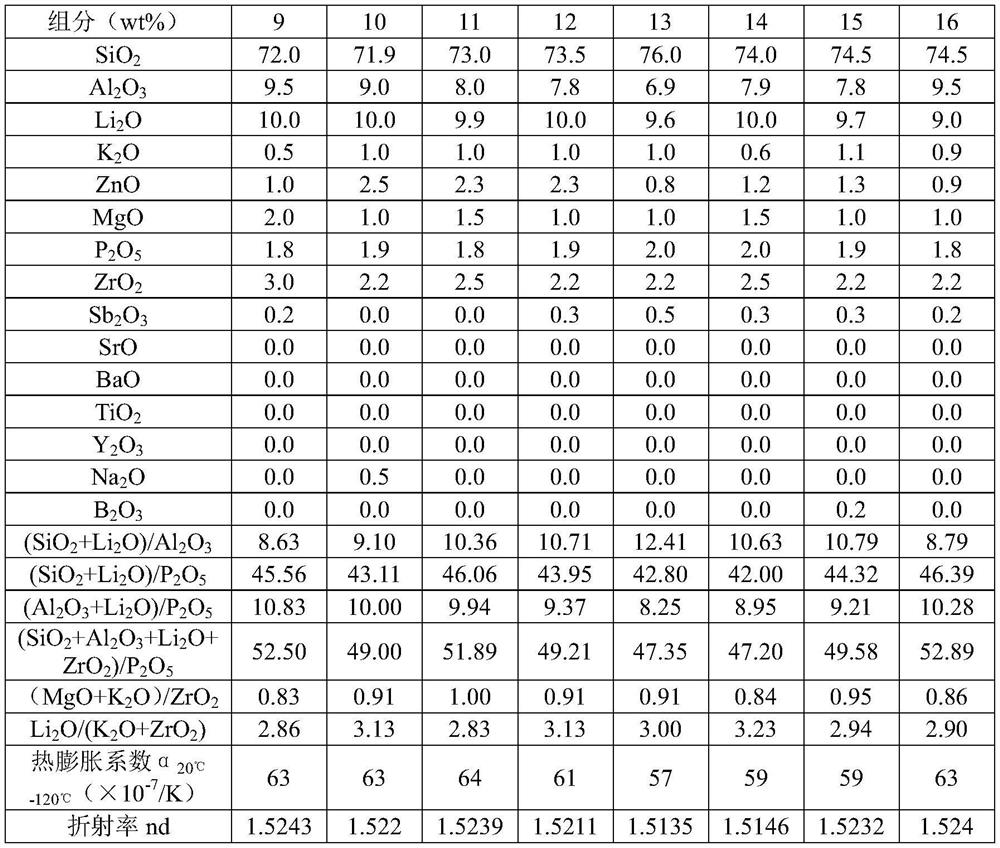

[0336] table 3.

[0337]

[0338]

[0339] Shown in following table 4~6 is glass-ceramic embodiment

[0340] Table 4.

[0341]

[0342]

[0343] table 5.

[0344]

[0345]

[0346] Table 6.

[0347]

[0348]

[0349] Shown in the following tables 7 to 9 are glass-ceramic product embodiments

[0350] Table 7.

[0351]

[0352]

[0353] Table 8.

[035...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| surface stress | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com