Carbon sleeve roller

A roll and carbon sleeve technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problem of difficult positioning of carbon sleeves and roll cores, and achieve the effect of reducing the failure rate of the unit, solving inconsistencies in deformation, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

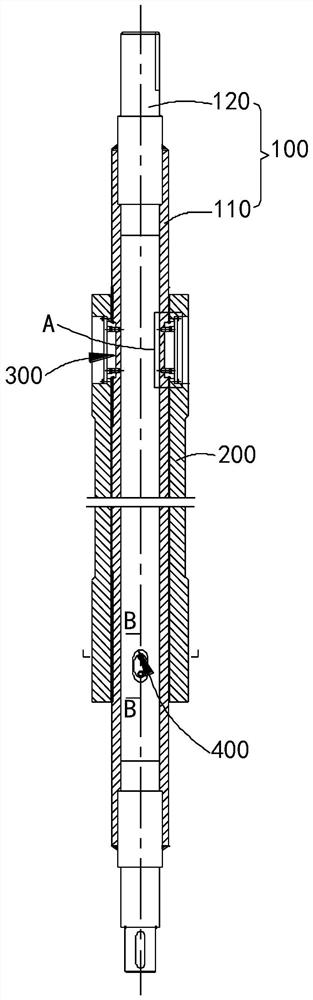

[0029] The embodiment of the present application solves the technical problem that the positioning of the carbon sleeve 200 and the roll core 100 is difficult in the prior art during strip annealing by providing a carbon sleeve roll.

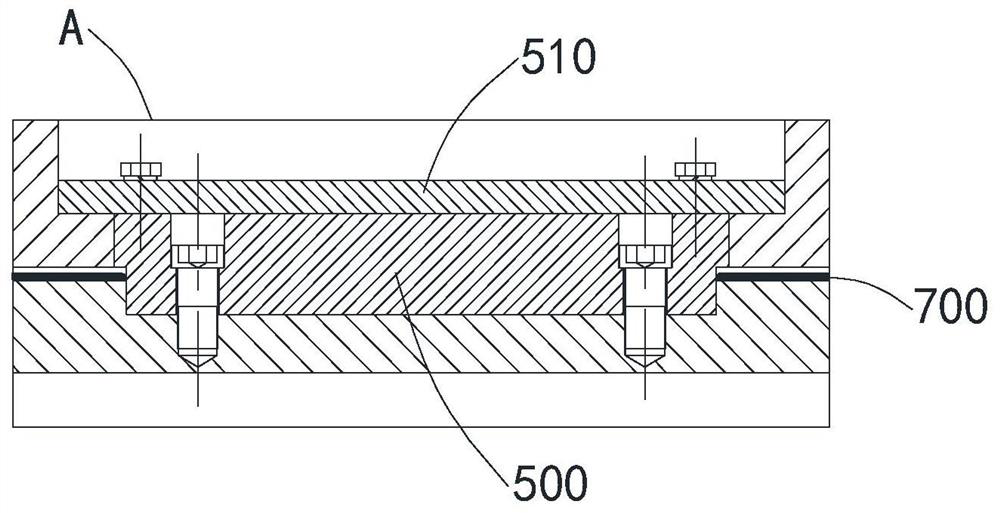

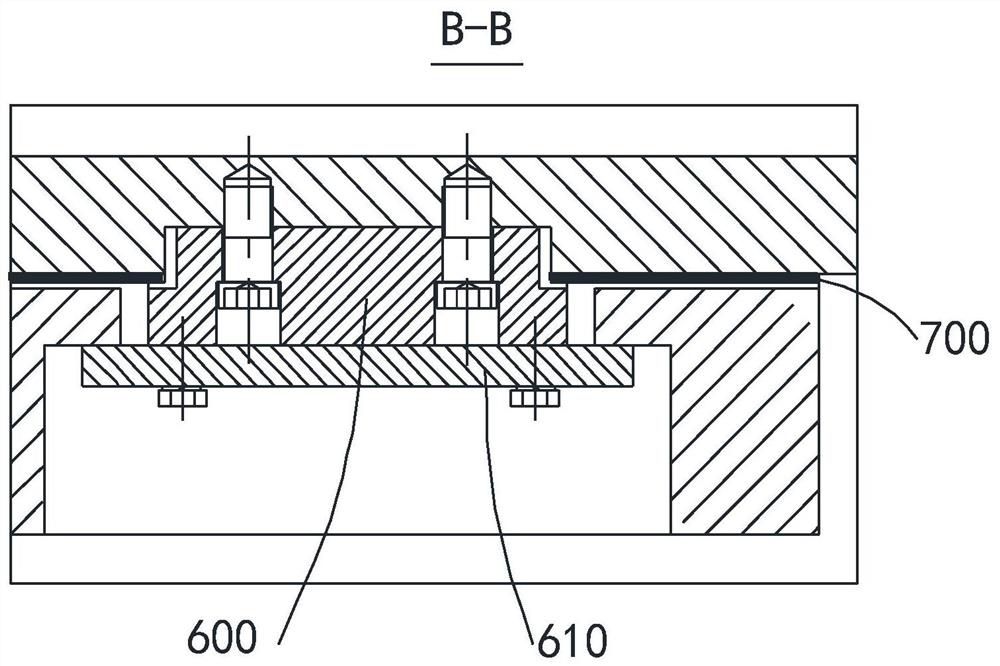

[0030] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows: a carbon sleeve roller includes a roll core 100 and a carbon sleeve 200, the carbon sleeve 200 is set on the roll core 100, and the carbon sleeve 200 is arranged along the axial direction. One end is provided with a positioning keyway 300 , and the other end is provided with a sliding keyway 400 to realize the axial positioning and circumferential positioning of the carbon sleeve 200 .

[0031] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com