Ironing-free pocket cover template capable of meeting human body comfort requirement

An iron-free bag flap and comfort technology, applied in the field of garment sewing, can solve the problems of not considering the capacity of the outer fabric of the bag flap, increasing the use of templates, reducing the efficiency of templates, etc., to simplify the steps of curling, The effect of simplifying the use process and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

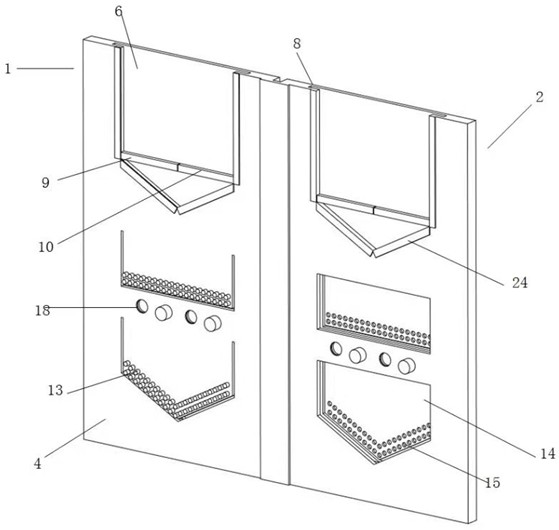

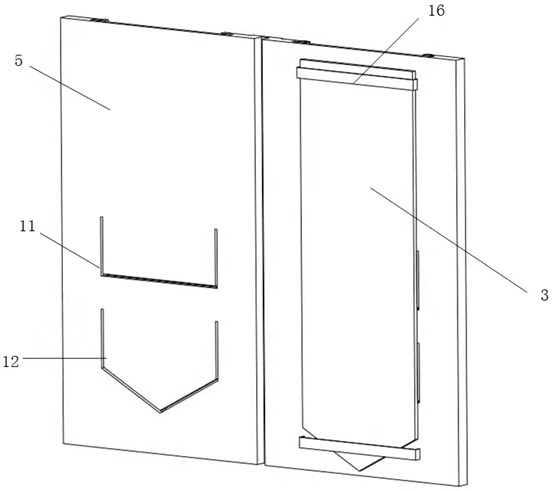

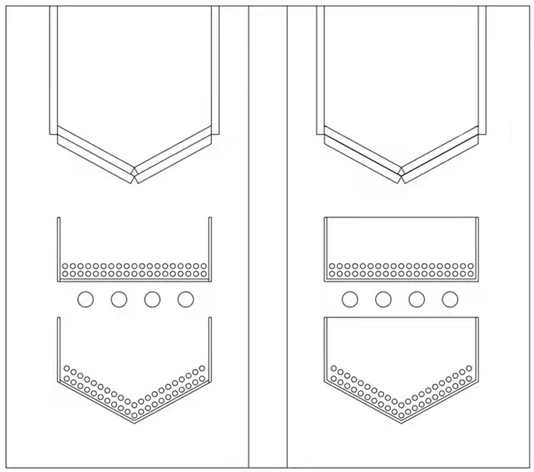

[0041] refer to Figure 1-Figure 6 As shown, a non-ironing bag cover template that satisfies human comfort, the template includes an upper template 1, a lower template 2 and a wedge-shaped pressing plate 3, and the upper template 1 is connected to the lower template 2;

[0042]The upper template 1 and the lower template 2 all include a first template 4 and a second template 5, the top of the first template 4 is provided with a hollow opening 6, and the outer sides of the hollow opening 6 on the upper template 1 and the lower template 2 are respectively There is a frosted positioning sticker 24 for the bag cover fabric, the bottom of the first template 4 and the second template 5 is provided with a sewing through groove, and a cushion layer 7 is provided between the first template 4 and the second template 5, The cushion layer 7 is placed on the left and right sides of the hollow opening 6 to form a groove 8, and the longitudinal length of the groove 8 directly leads to the pla...

Embodiment 2

[0055] refer to Figure 1-Figure 5 As shown, a non-ironing bag cover template that satisfies human comfort, the template includes an upper template 1, a lower template 2 and a wedge-shaped pressing plate 3, and the upper template 1 is connected to the lower template 2;

[0056] The upper template 1 and the lower template 2 all include a first template 4 and a second template 5, the top of the first template 4 is provided with a hollow opening 6, and the outer sides of the hollow opening 6 on the upper template 1 and the lower template 2 are respectively There is a frosted positioning sticker 24 for the bag cover fabric, the bottom of the first template 4 and the second template 5 is provided with a sewing through groove, and a cushion layer 7 is provided between the first template 4 and the second template 5, The cushion layer 7 is placed on the left and right sides of the hollow opening 6 to form a groove 8, and the longitudinal length of the groove 8 directly leads to the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com