Two-way composite floor slab with four sides without rib extending and free of formwork supporting and dismounting and construction method thereof

A technology of stacking floor and four sides, applied in the direction of floor, building structure, building, etc., can solve the mismatch between the prefabricated plate pressing grooves on both sides of the joint, unfavorable work efficiency guarantee and cost control, affecting the insertion of connecting steel bars into the pressing groove, etc. problems, to achieve the effect of improving the versatility of the template, convenient positioning, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

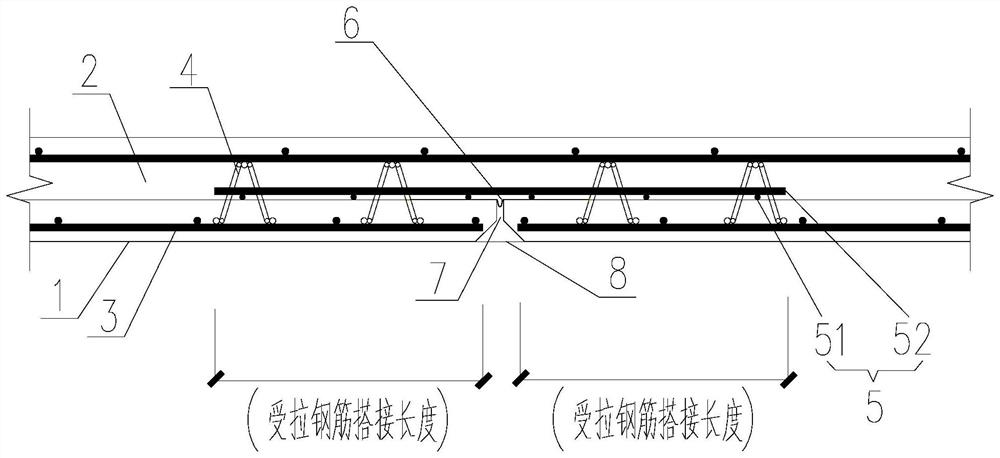

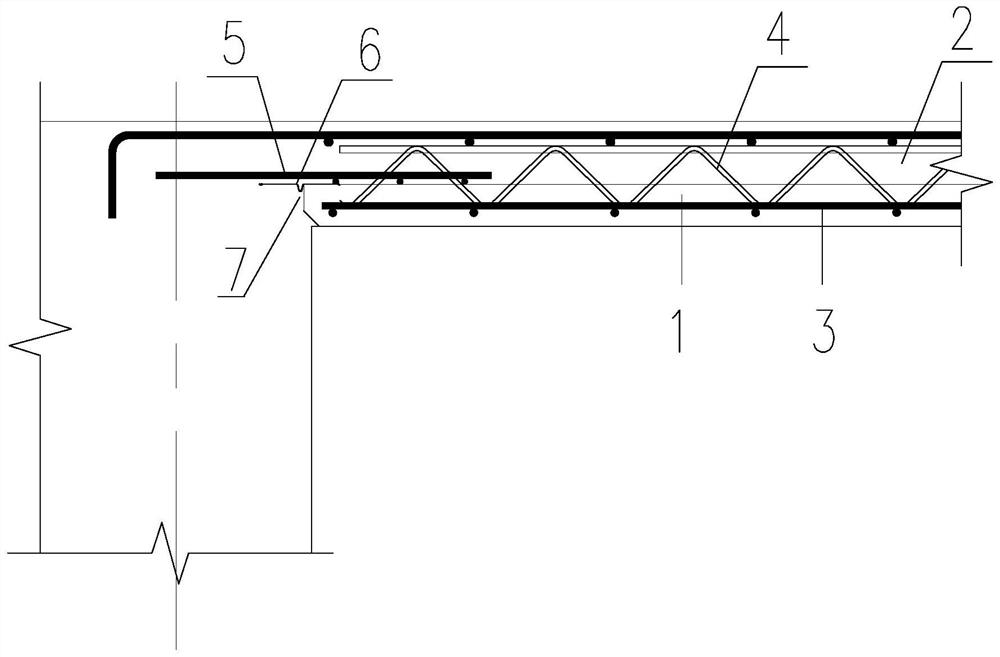

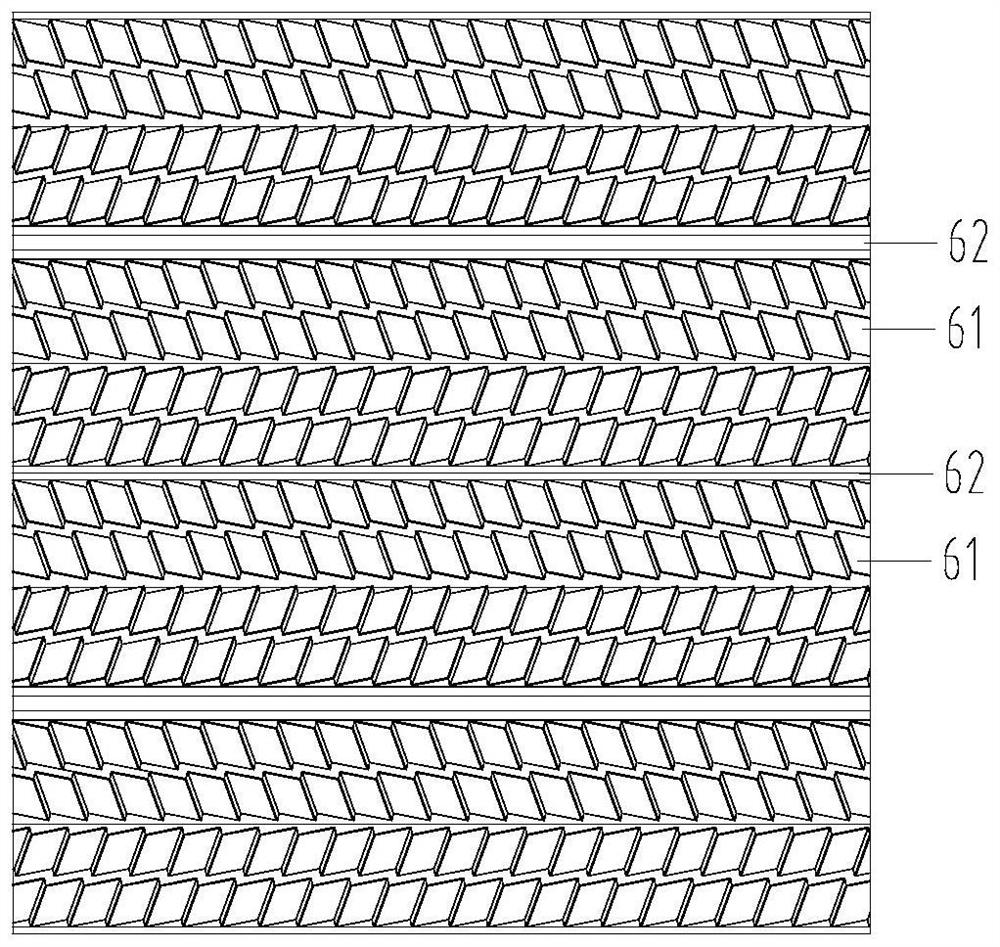

[0038] see figure 1 and figure 2 , which shows a two-way laminated floor slab with no ribs on four sides and no formwork removal provided by this embodiment, which includes at least two prefabricated slabs 1, a cast-in-place laminated layer 2, and a prefabricated slab bottom stressed reinforcement mesh 3 , a number of truss reinforcement bars 4, additional reinforcement mesh 5, steel formwork mesh 6 and patchwork 7.

[0039] There are no ribs on the four sides of the prefabricated slab 1, and several truss steel bars 4 are vertically installed in the prefabricated slab 1 and the cast-in-place composite layer 2. Moreover, several truss reinforcement bars 4 are densely arranged near the side of the prefabricated slab 1 .

[0040] The prefabricated slab bottom stress reinforcement mesh 3 is horizontally laid on the bottom of the prefabricated slab 1 .

[0041] The joint 7 is located between two adjacent prefabricated panels 1, and a gap of a certain width is reserved at the j...

Embodiment 2

[0068]This embodiment provides a two-way laminated floor slab with no ribs on four sides and no support and formwork removal. The difference from Embodiment 1 is that the anti-cracking treatment layer 8' of this embodiment adopts a dry construction method. Please refer to Figure 8 , showing the structure of the anti-cracking treatment layer. The anti-cracking design of the joints at the bottom of the dry construction method is combined with the structure of the board edges. It also uses elastic materials 9 to seal the joints, and is connected by metal or non-metal gussets. The masking and covering of the seam of the board is carried out by means of a method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com