Fireproof, waterproof and shockproof protection device for bridge cable

A bridge cable and earthquake protection technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of rising cable temperature field, lower cable elastic modulus, bridge collapse, etc., to reduce maintenance costs, reduce Lasso disease, the effect of ensuring safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

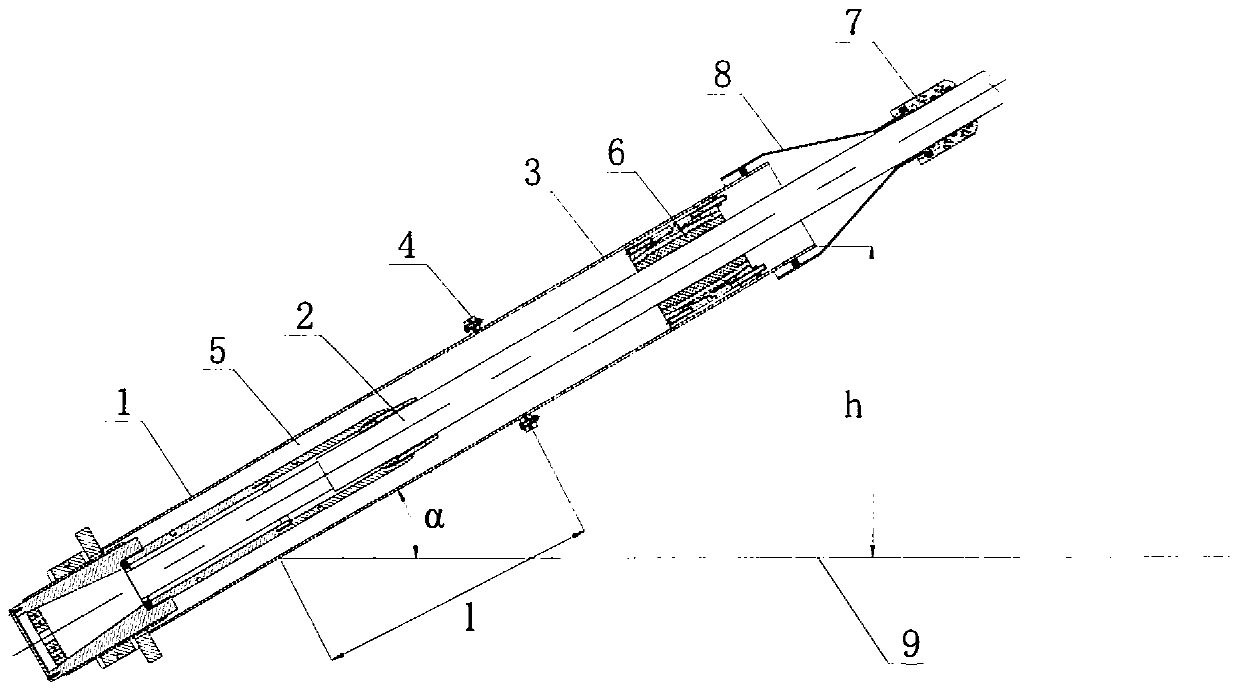

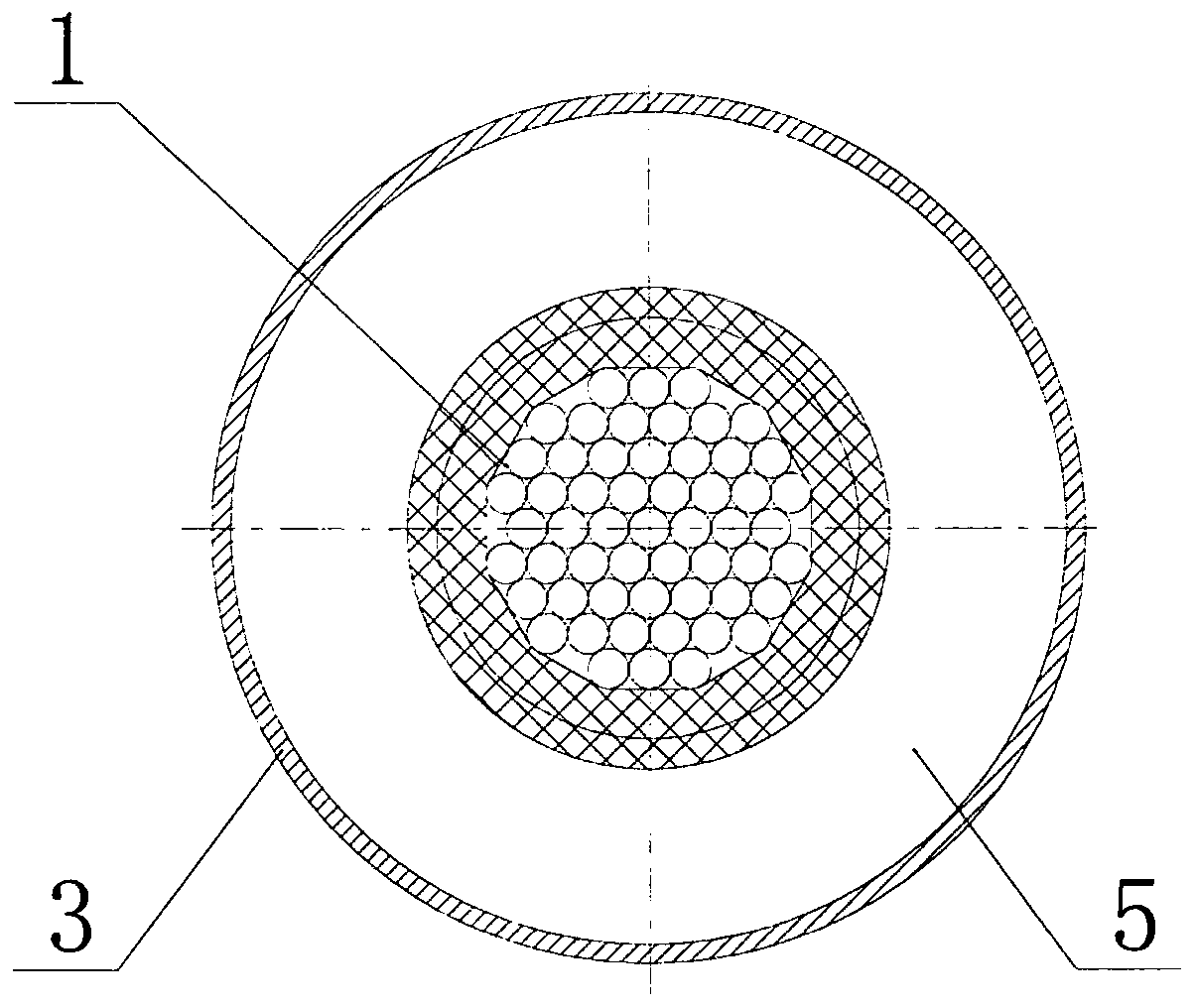

[0031] like figure 1 , figure 2 As shown, a fireproof, waterproof, and shockproof protection device for a bridge cable in this embodiment includes a pre-embedded conduit 1 arranged obliquely, and a drag cable 2 is worn inside the pre-embedded conduit 1. An elongated steel pipe 3 is arranged above the conduit 1. The elongated steel pipe 3 is set on the cable 2. The outer diameter of the elongated steel pipe 3 is the same as that of the pre-embedded conduit 1. The blue connector 4 is connected, the embedded conduit 1 and the lengthened steel pipe 3 are provided with a fireproof layer 5, the length L=h / sinα-l of the lengthened steel pipe 3, wherein h is the height of the vehicle fire source (general oil The tanker fire is the most serious, and the flame height is also the highest, whichever is the height), α is the angle between the cable and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com