Interstage sealing ring sealing structure

A technology of sealing structure and sealing ring, applied in the direction of preventing leakage, stator, jet propulsion device, etc., can solve the difficulty of disassembling and assembling the spring pressing bolt of the middle face, and does not solve the problems of sealing, inconvenient installation and disassembly, etc. Improved maintainability, reduced risk of seal failure, and easy-to-achieve effects of seal structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

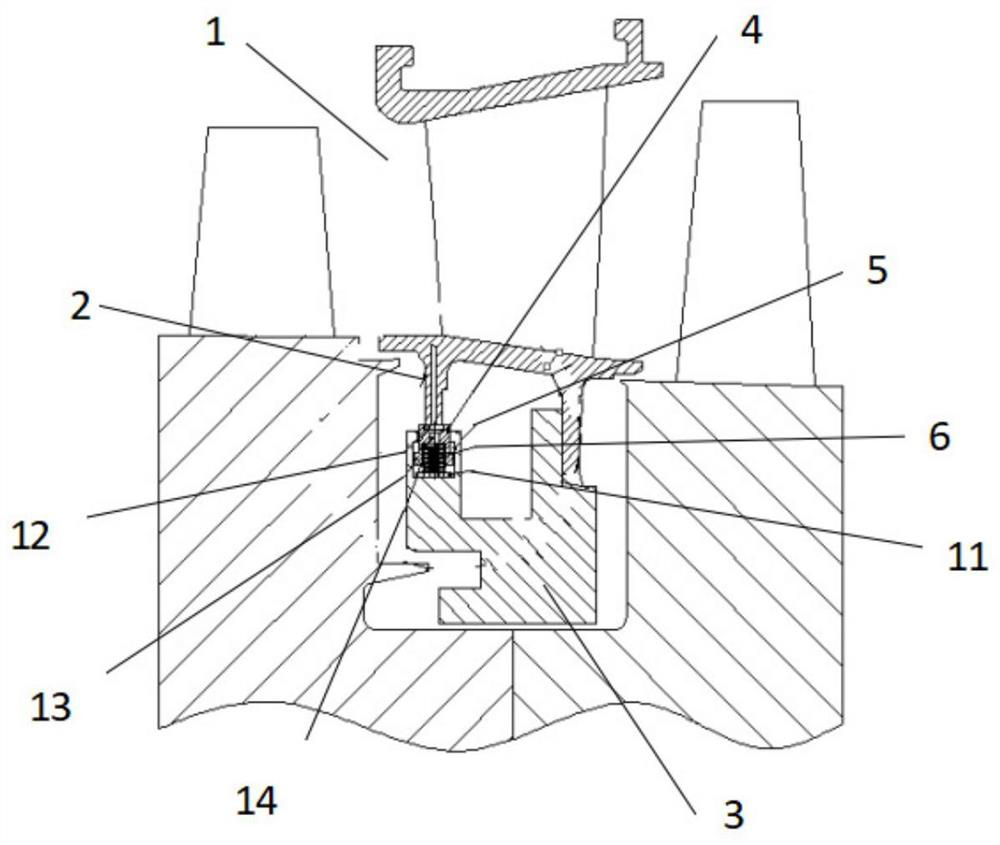

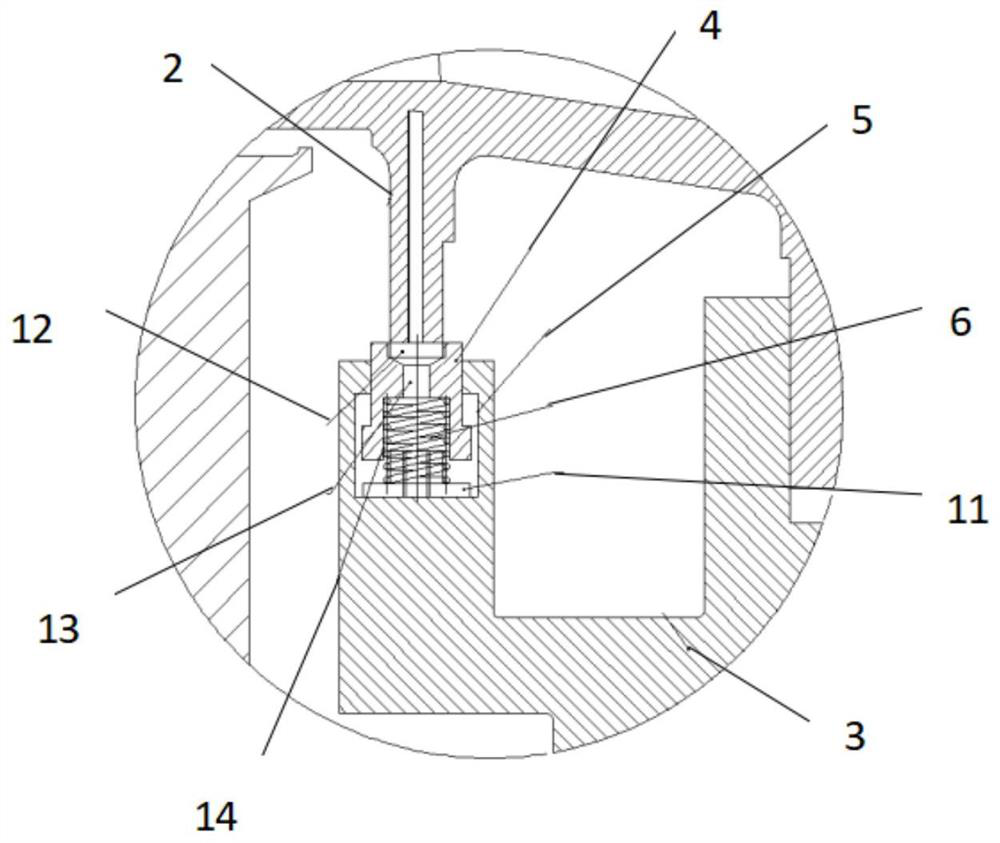

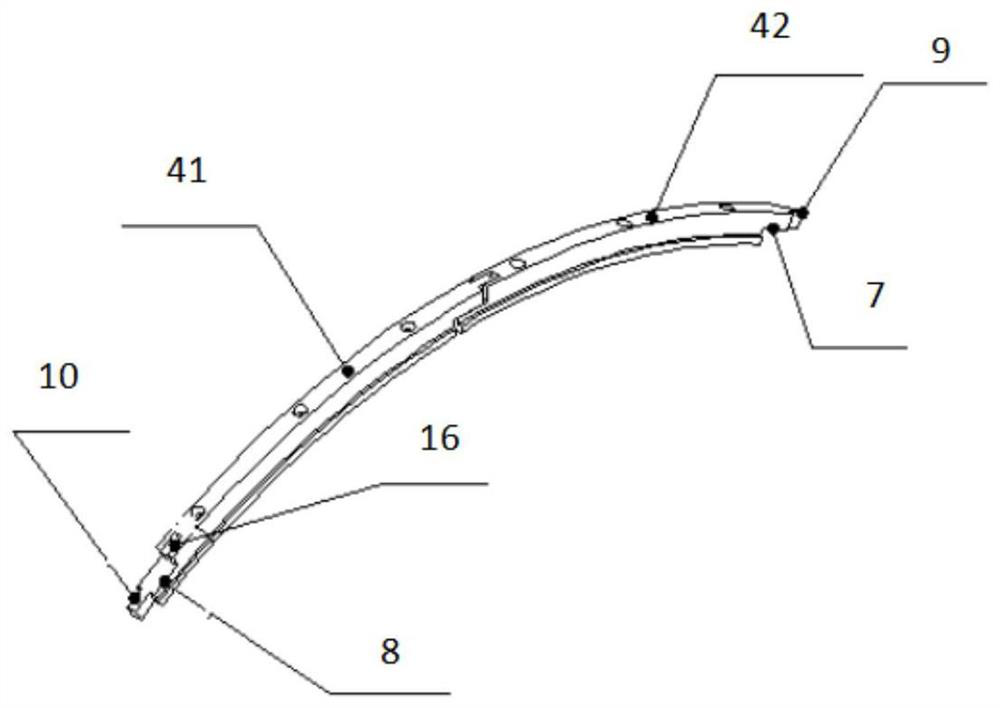

[0035] according to Figure 1-Figure 9The interstage sealing ring sealing structure shown includes the turbine stator blade 1, the sealing extension section 2 of the inner shroud of the stator blade, the interstage sealing ring 3, the T-shaped sealing ring body 4, the spring 6, and the T-shaped sealing ring. The sealing ring overlaps and seals the first extending section 7, the T-shaped sealing ring overlaps and seals the second extending section 8, the T-shaped sealing ring is embedded to seal the first extending section 9, and the T-shaped sealing ring is embedded to seal the second extending section 10. Gasket 11, T-shaped sealing ring guide hole 13; the T-shaped sealing ring body 4 includes a first T-shaped sealing ring 41 and a second T-shaped sealing ring 42; both ends of the T-shaped sealing ring body 4 Extending sections at both ends are provided, wherein, the end face of the first T-shaped sealing ring 41 is provided with a T-shaped sealing ring lapped to seal the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com