Splicing pneumatic one-way micro valve manufactured through 3D printing

A 3D printing, one-way technology, applied in the field of microfluidics, can solve the problems of switching microvalve or regulating flow error, automatic control link response delay, complex microvalve structure, etc., to avoid backflow, simple one-way flow structure, The effect of simplifying the connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

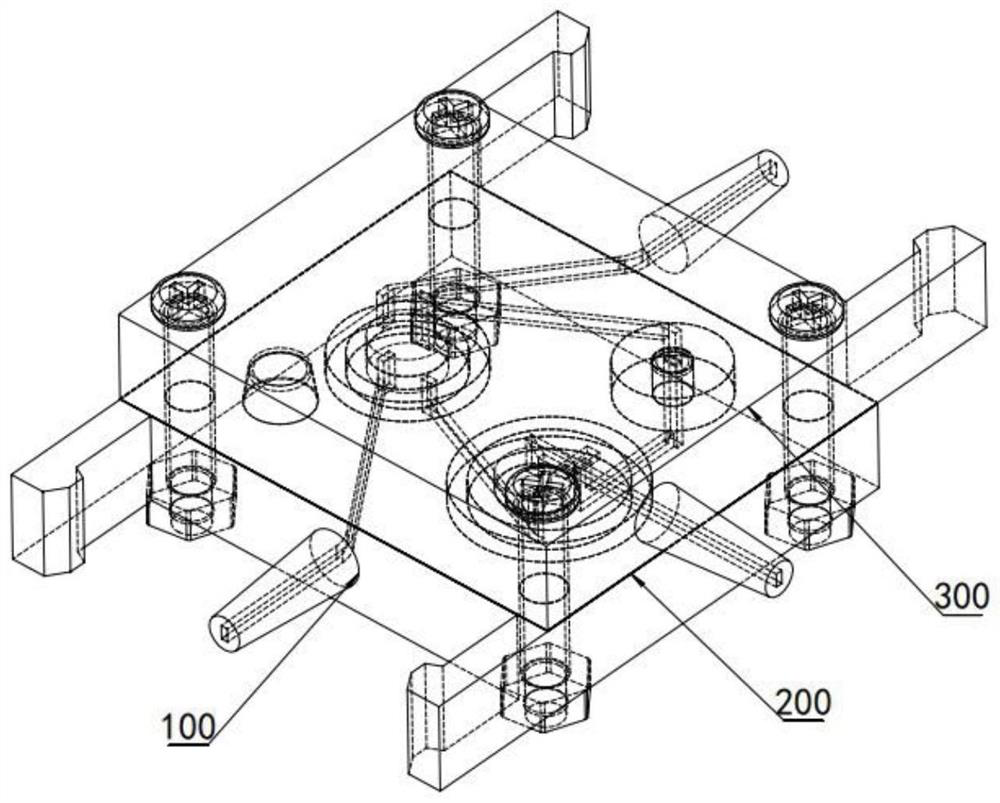

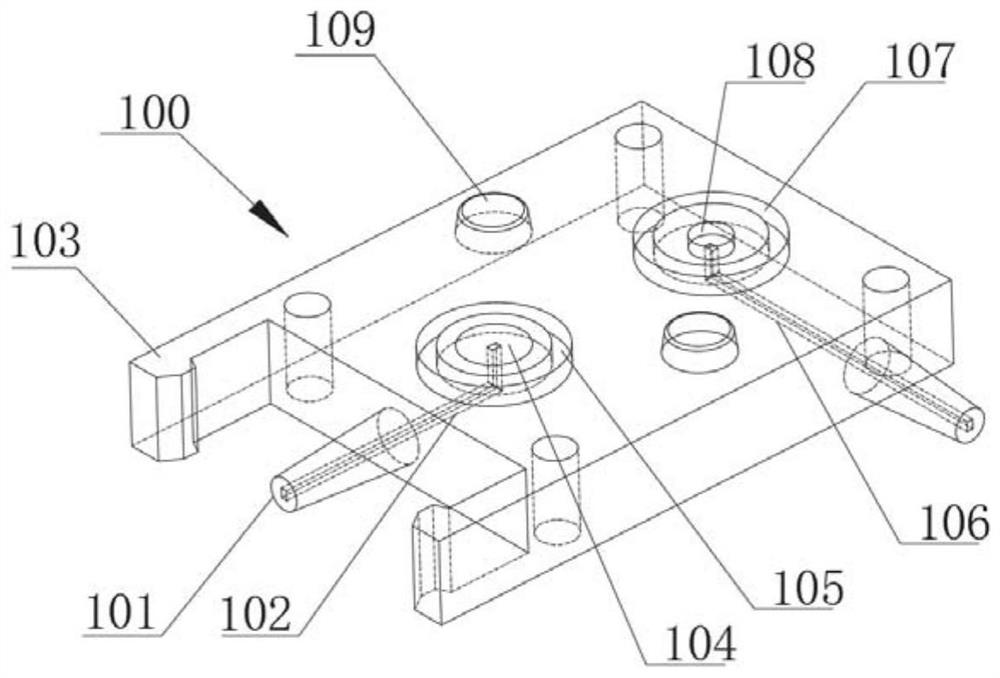

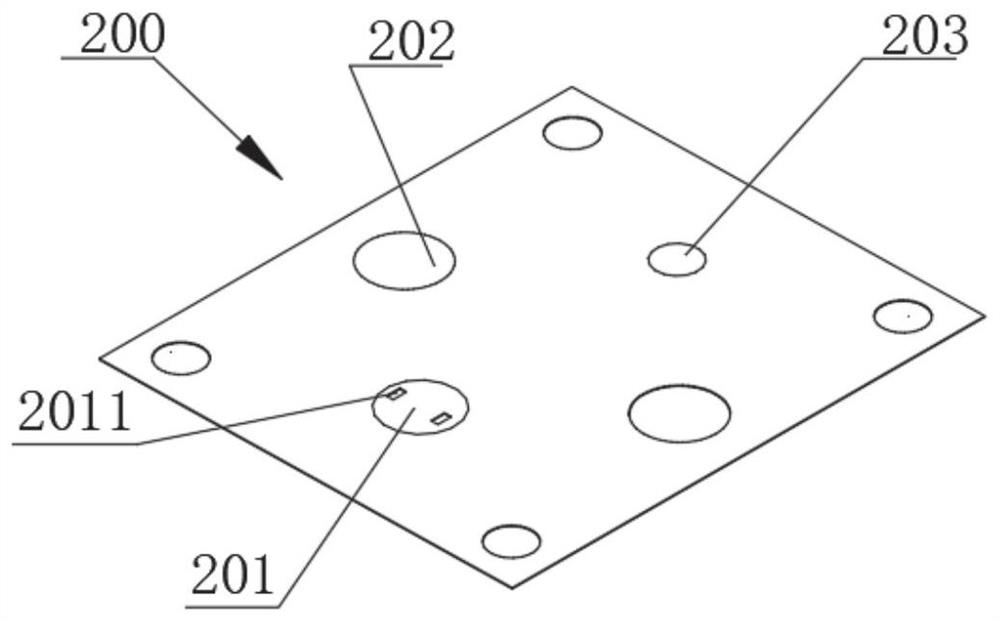

[0034] Such as figure 1 , Figure 5 and Figure 8 As shown, the spliceable pneumatic one-way microvalve produced by 3D printing in this embodiment includes an air channel block 100, a deformable film 200 and a flow channel block 300, and the deformable film 200 is sealed and connected to the top surface of the air channel block 100 and the flow channel block 300 between the bases;

[0035] Such as Figure 2-Figure 4 As shown, the top surface of the airway block 100 is provided with a lower one-way chamber 104 for communicating with an external fluid source, and the bottom surface of the flow channel block 300 is provided with an upper one-way chamber 301 corresponding to the lower one-way chamber 104, and an upper one-way chamber 301 corresponding to the upper one-way chamber. A communicating outflow chamber 305 that can be connected to the cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com