Salt spray test box for eddy current circulation type ship steel plate corrosion resistance detection

A salt spray test and circulation technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve problems such as poor practicability, improve convenience, reduce labor intensity, and improve uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

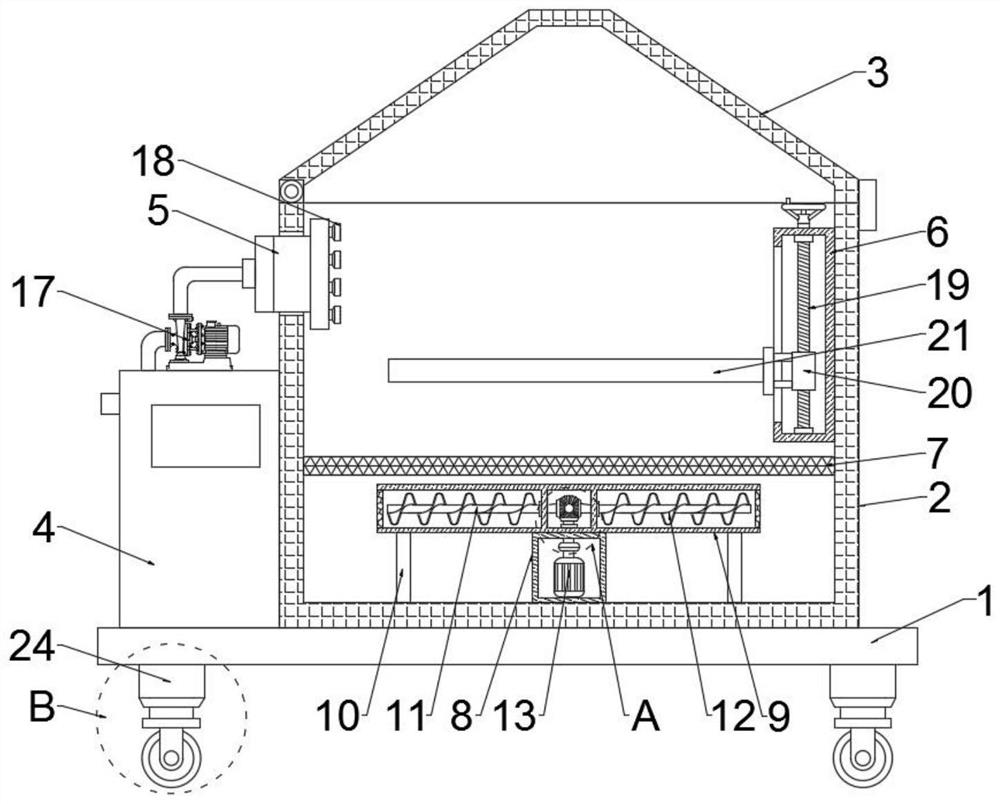

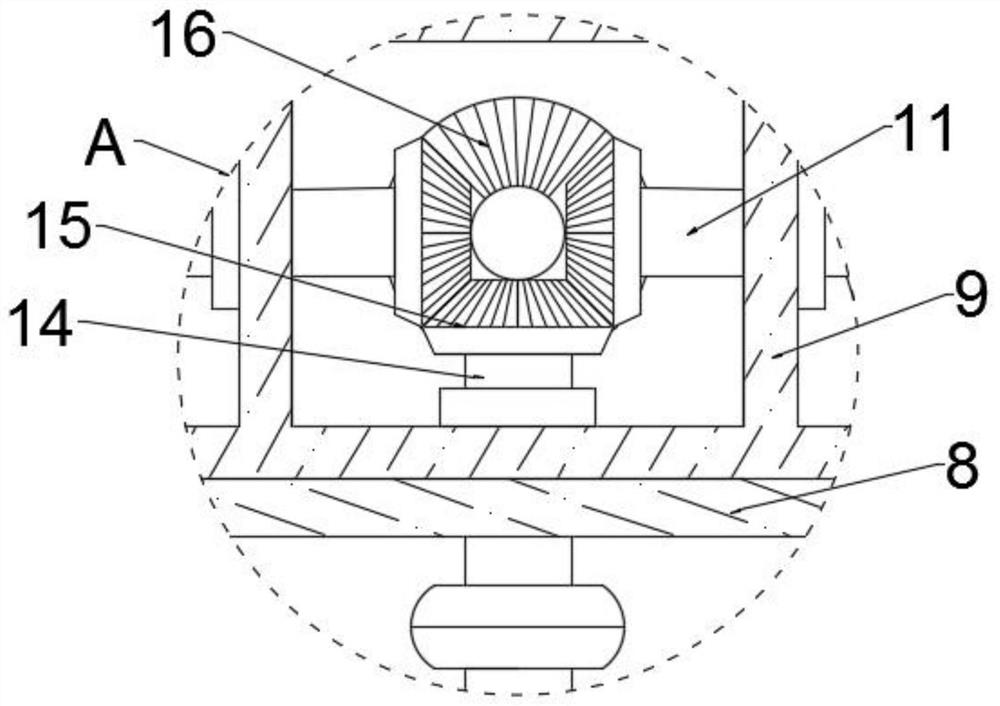

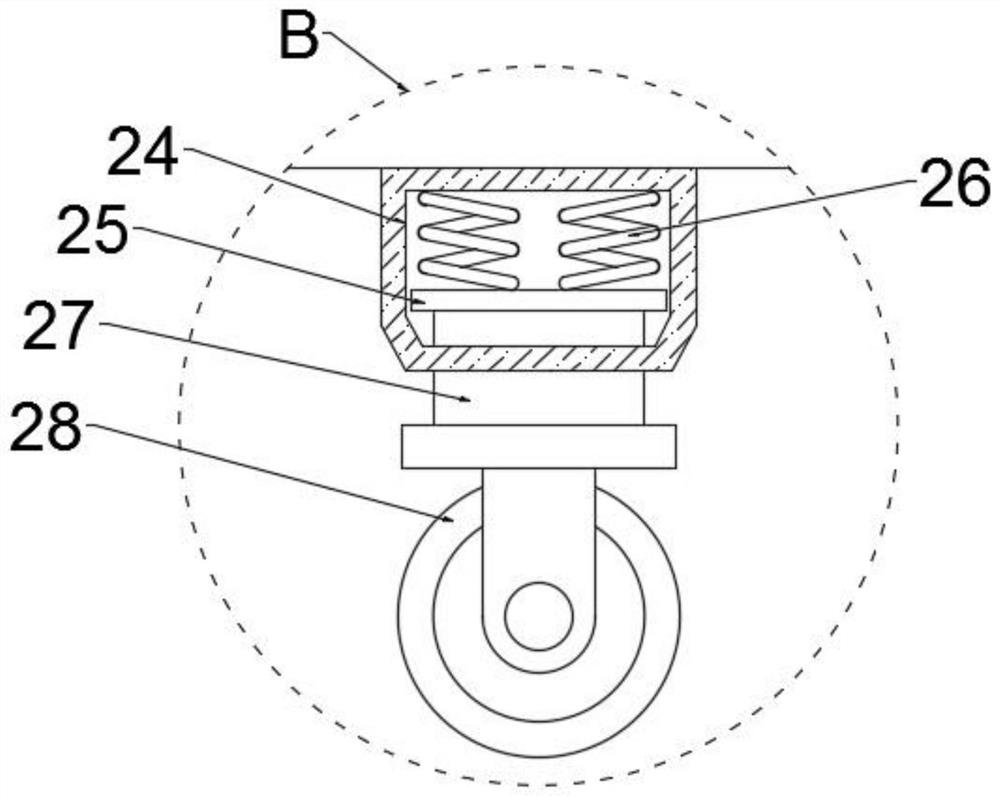

Embodiment 1

[0022] Embodiment 1: see Figure 1-5 , an eddy current circulation salt spray test chamber for corrosion resistance detection of ship steel plates in the present invention, comprising a base 1, the base 1 is in the shape of a rectangular plate arranged horizontally, and the middle part of the top surface of the base 1 is fixedly connected with a test chamber with an opening facing upwards 2. One side of the top opening of the test box 2 is hinged with a box cover 3 through a hinge, the base 1 on one side of the test box 2 is fixedly connected with the solution box 4, and the top of one side of the test box 2 is provided with a circular installation port for installation. A circular booster box 5 is fixed horizontally in the mouth; a rectangular box 6 is vertically fixed on the other side of the test box 2, and a lifting assembly is arranged in the rectangular box 6; a partition is fixed horizontally in the lower part of the test box 2 Net 7, the middle part of the inner bottom...

Embodiment 2

[0027] Embodiment 2: when the present invention is used, at first the motor 13 and the booster pump 17 are electrically connected to the external power supply respectively through wires; The screw 19 is driven to rotate by rotating the adjusting hand wheel, and the rotation of the screw 19 facilitates the lifting and moving of the threaded cylinder 20, and the lifting and moving of the threaded cylinder 20 facilitates the lifting of the sliding plate at the outer end of the connecting rod, and the lifting of the sliding plate It is convenient to drive the bearing frame 21 to drive the ship steel plate to be tested to the lower part of the test chamber 2; the lift assembly is convenient to lift and move the ship steel plate to be tested, which is convenient for the operator to quickly pick and place the ship steel plate, effectively improving the The convenience of ship steel plate detection effectively reduces the labor intensity of operators when placing ship steel plates; it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com