Bearing capacity evaluation method of sandy soil box

An evaluation method and technology of bearing capacity, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of difficult operation of the main installation project of the pipeline, leakage of liquefied gas, affecting the pipeline, etc., to reduce the impact, The effect of reducing the damage of buried pipelines and evaluating the results accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

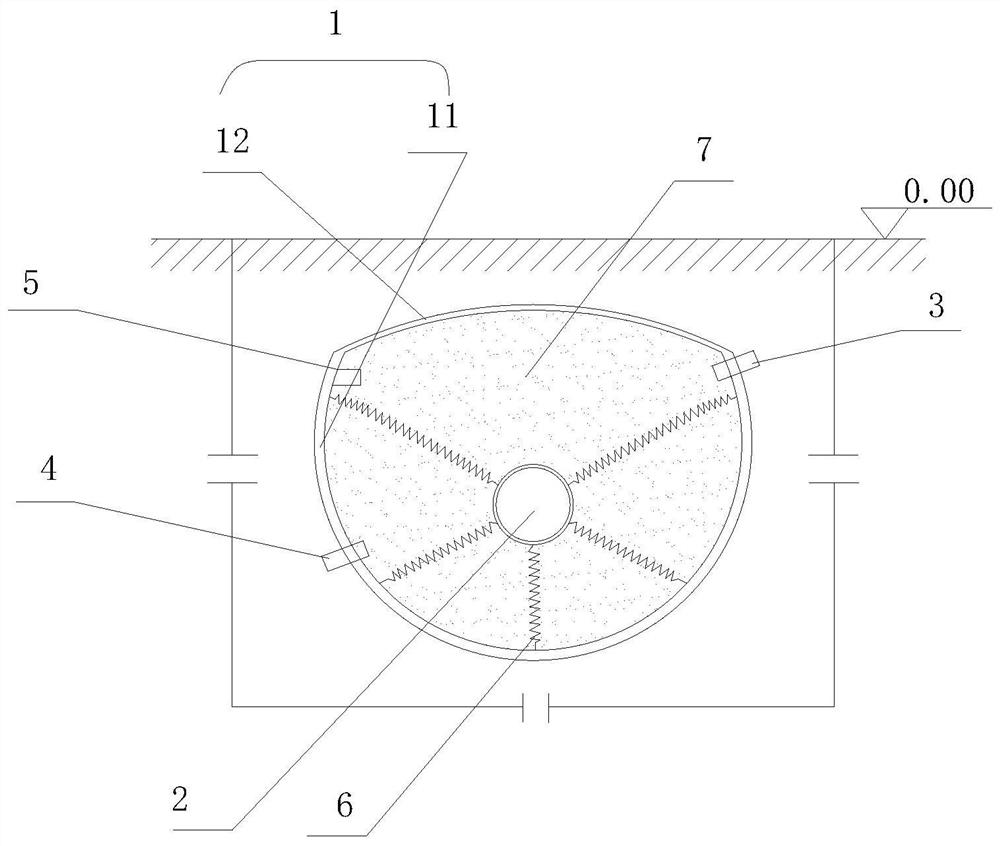

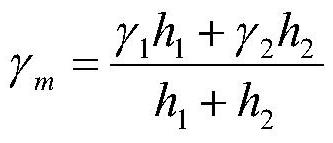

[0085] Assume that there is a fire engine load q=20kN / m acting on the upper part of the sand box 2 , It is confirmed by geotechnical engineering survey that the place where the sand box is buried at the ground fissure is cohesive soil. its severity r 1 =18kN / m 3 , the thickness of the soil above the sand box soil layer is h 1 = 3m, the soil weight r within the design range of the height of the sand box 2 =20kN / m 3 , corresponding to the thickness of the soil layer h 2 =2.31m, the width of the sand box is b=2m, the length direction of the sand box is calculated as 1m, and the self-weight of the soil above the sand box within the range of the soil layer is G 0 , the self-weight within the scope of the sand box is G 1 , the buried depth of the sand box is d=2.5m, and the characteristic value of the bearing capacity of the basement is obtained from geotechnical engineering investigation f ak =160kPa, porosity ratio e=0.8, liquid index I L = 0.78.

[0086] It is calculate...

Embodiment 2

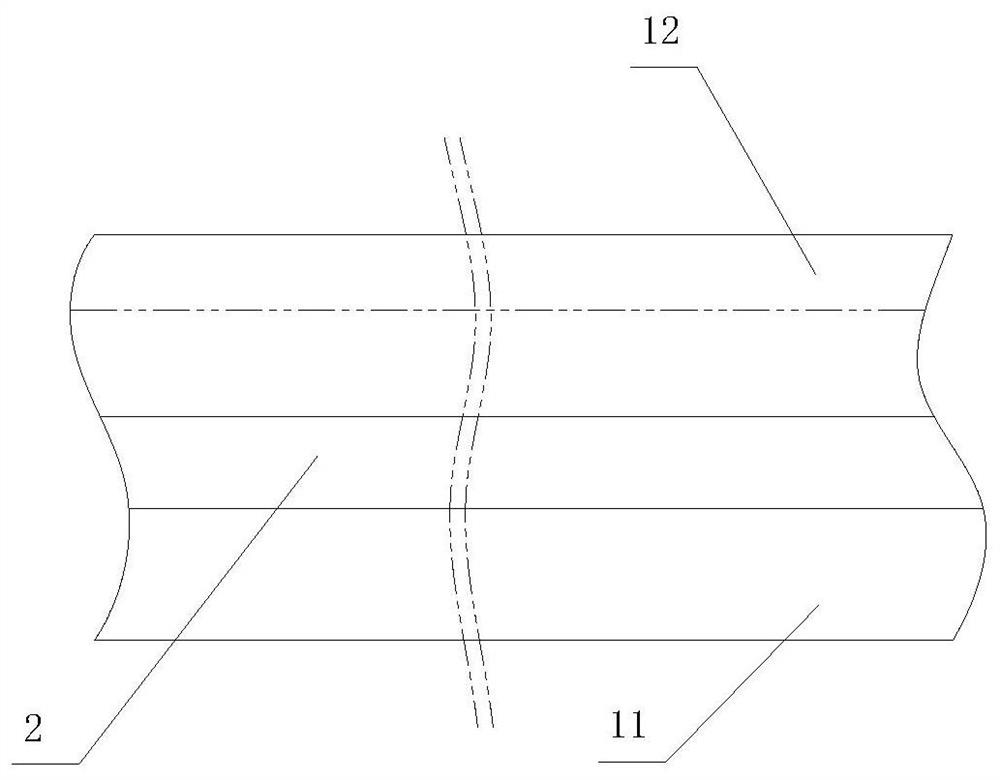

[0092] The buried depth of the sand box is d, the width of the sand box is b, the length of the sand box is l, the height of the sand box is H, and the bulk density of the soil on the top of the sand box is r 1 =18kN / m 3 , the overall bulk density of the sand box r 2 =20kN / m 3 (Including the total bulk density of sand and water inside the sand box). The self-weight of the soil above the sand box within the soil layer is G 0 , the self-weight within the scope of the sand box is G 1 , the buried depth of the sand box is d=4m.

[0093] It is calculated by the following formula:

[0094]

[0095] G 0 =bld×18=18bld

[0096] G 1 =blH×20=20blH

[0097] therefore,

[0098] Among them, the height H of the sand box is 3m, and the characteristic value f of the foundation bearing capacity obtained from the geotechnical engineering investigation is ak =160kPa, porosity ratio e=0.8, liquid index I L = 0.78.

[0099] f a =f ak +η b γ(b-3)+η d gamma m (d-0.5)=160+1.6×18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com