Manufacturing and quality management method for digital remote rocket projectile guidance cabin

A quality management and rocket technology, applied in the field of digital manufacturing, can solve the problem that the production and manufacturing management form cannot meet the new requirements of the army equipment manufacturing and quality management, etc., achieving the effect of strong demonstration, remarkable effect, and avoiding missed inspections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

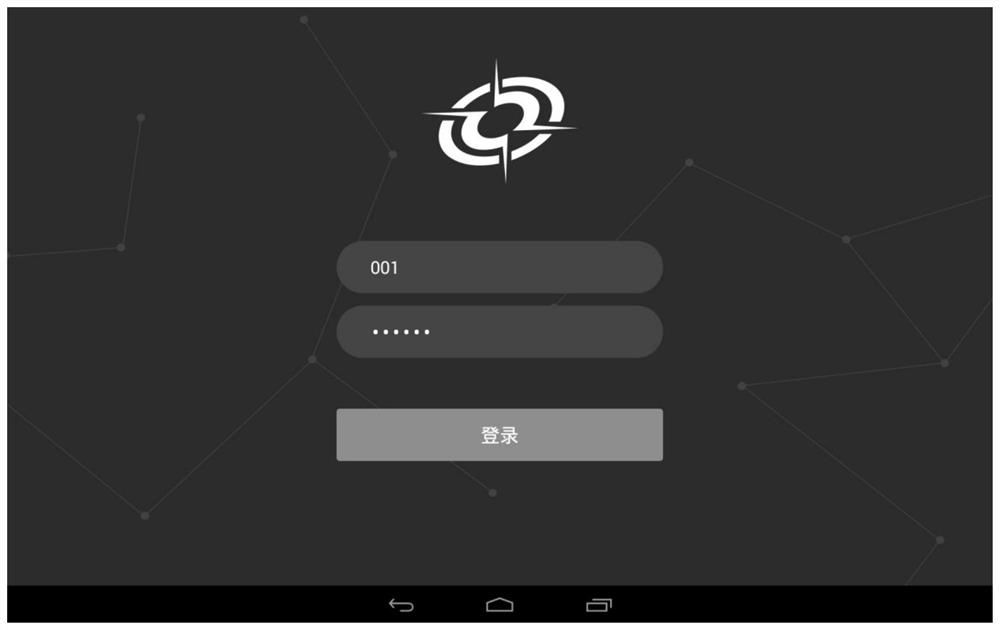

[0032] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0033] Aiming at the manufacturing of the guidance cabin of the remote guided rocket, a set of digital remote rocket guidance cabin manufacturing and quality interactive management equipment was developed in combination with the actual production situation of the factory. This equipment uses modern computer and multimedia technology to load the digital interactive system of manufacturing and quality management. The workshop assembly site establishes an information visualization human-computer interaction system, and transmits relevant information such as product design, assembly process and inspection to the production site in digital form. This set of equipment overcomes the problems of poor visualization of paper-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com