Production workshop management software system, computer, mobile phone and tablet terminal

A technology of production workshop and management software, applied in computing, manufacturing computing system, image data processing, etc., can solve problems such as imperfect statistical management, chaotic work arrangement, and inability to realize remote workshop production management.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] refer to figure 1 , shows a schematic structural diagram of an embodiment of a production workshop management software system of the present invention, the system includes: an input module 101 and a display module 102,

[0025] The input module 101 is configured to receive a request instruction input by a user according to a preset item label;

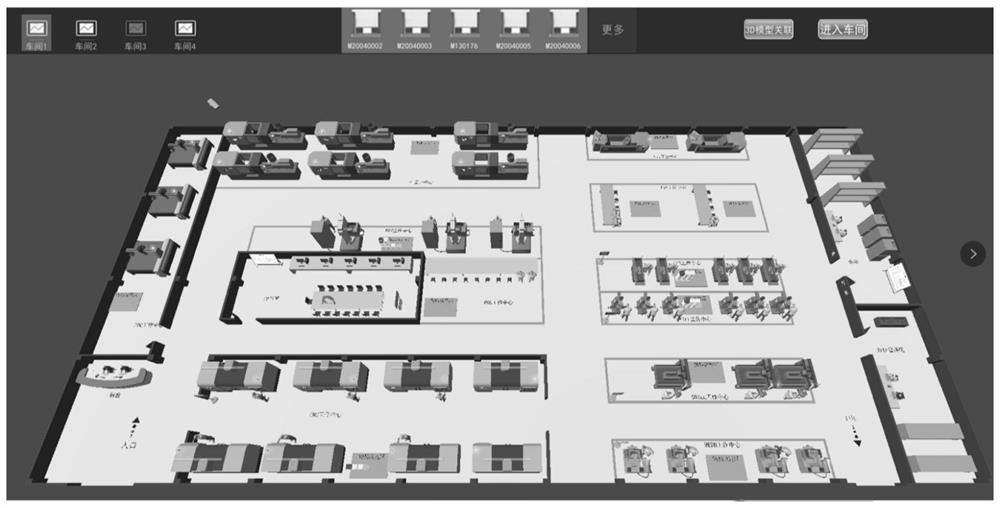

[0026] The display module 102 is used to display the parameter information corresponding to the item label according to the request instruction input by the user, wherein the parameter information includes: production workshop location information, operator configuration information, operator profile information, One or more of production order content information, work plan inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com