Aluminum secondary battery and its electrolyte

An aluminum secondary battery, electrolyte technology, applied in secondary battery, electrolyte battery manufacturing, non-aqueous electrolyte battery and other directions, can solve the problems of strong electrolyte corrosion, unfavorable large-scale application, battery shell corrosion, etc., to achieve cycle Good stability, good application prospects, high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

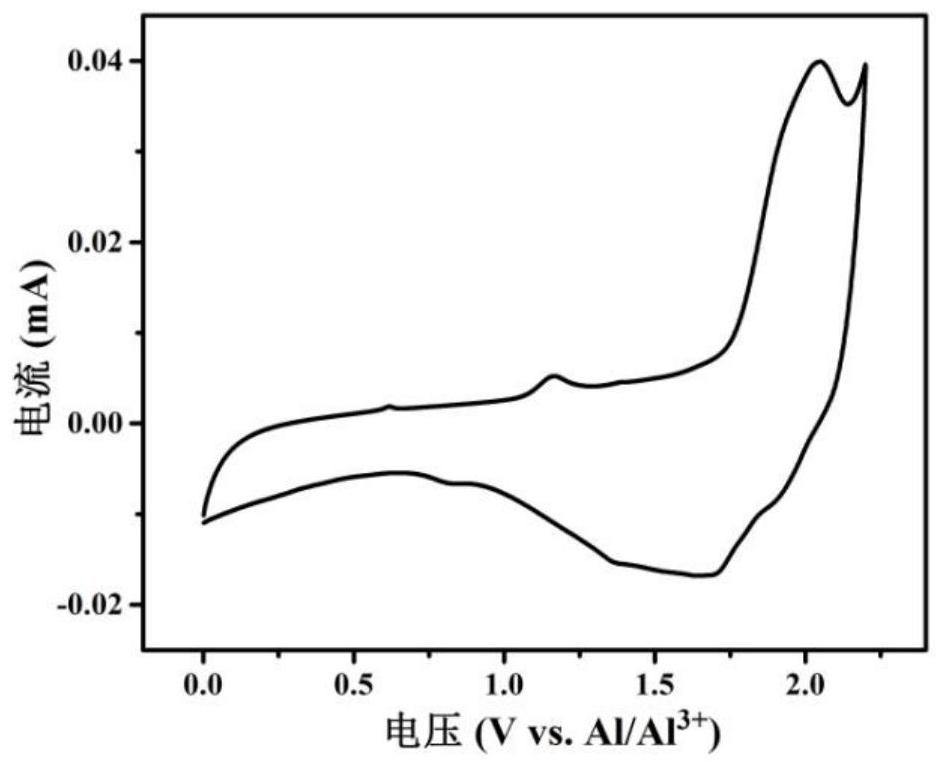

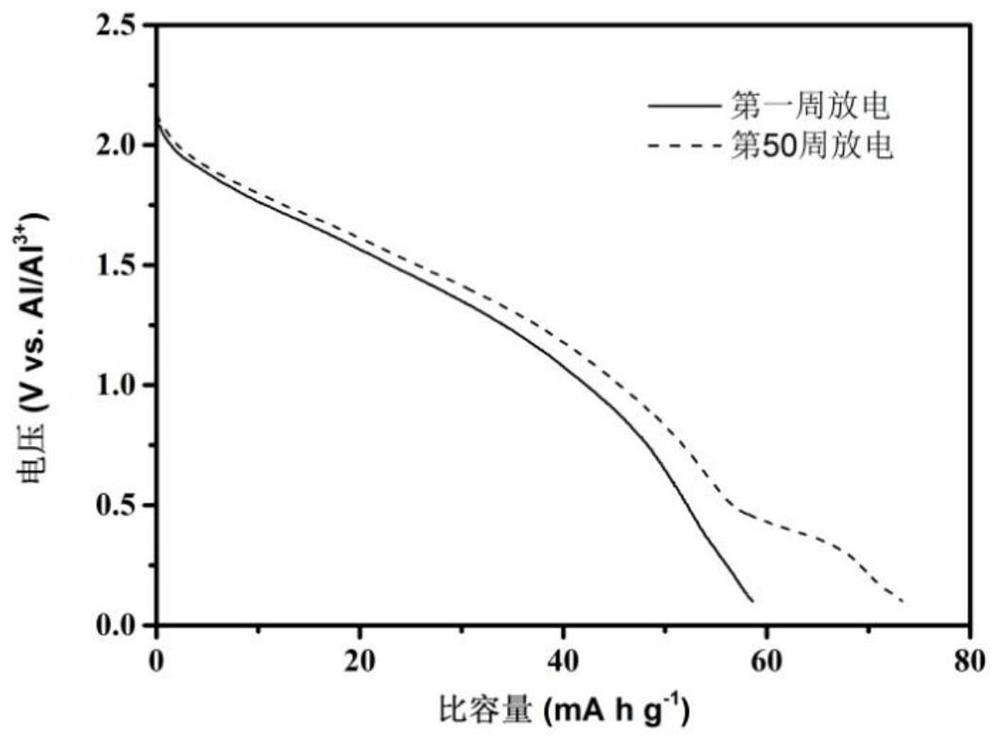

Method used

Image

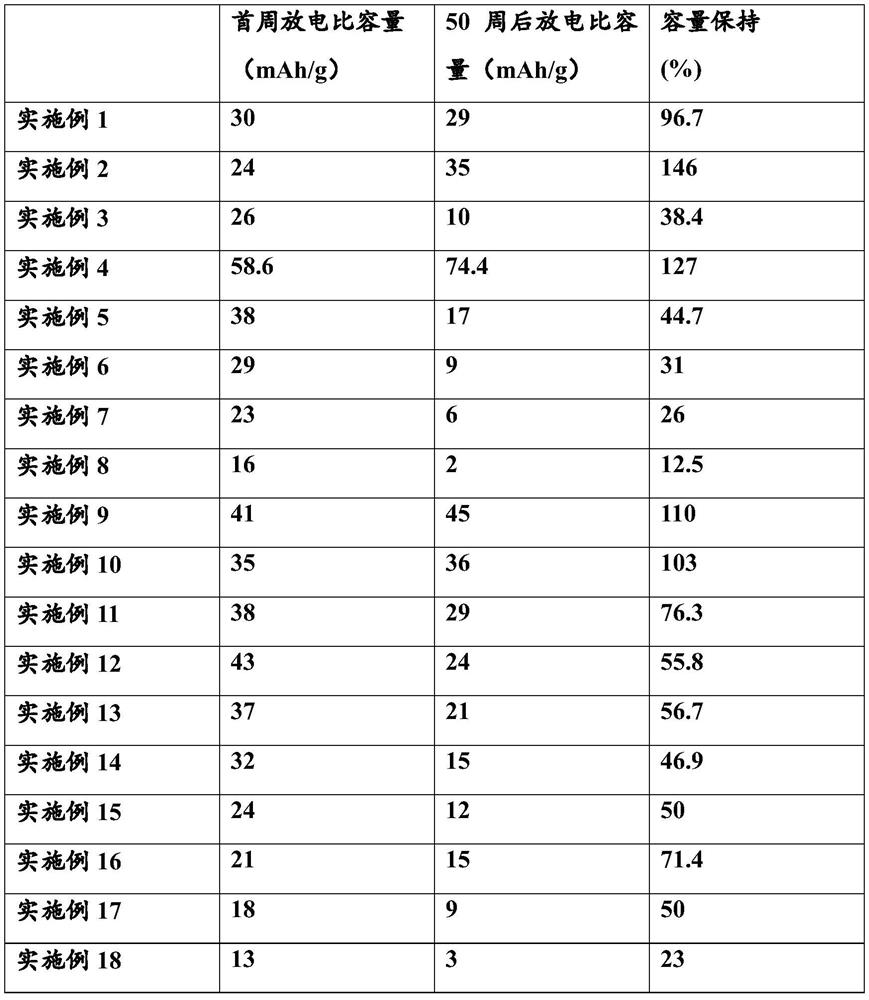

Examples

Embodiment 1

[0022] In a glove box containing an inert gas, slowly add aluminum trichloride to methyl urea, wherein the molar ratio of aluminum trichloride to methyl urea is 1.5, stir while adding, after the addition is completed, at a temperature of 80°C Stir for 30 minutes at a magnetic stirring speed of 300 rpm to obtain an electrolyte solution.

Embodiment 2

[0024] Adopt dimethyl urea to replace the methyl urea in embodiment 1, other are the same as embodiment 1.

Embodiment 3

[0026] Adopt trimethylurea to replace the methylurea in embodiment 1, other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com