Metal smelting blast furnace slag bottom filtering method filtering system

A blast furnace slag and metal smelting technology, which is applied in fixed filter element filters, filtration separation, separation methods, etc., can solve the problems of inconvenient recycling of slag particles, shorten the service life of the filter layer, etc., so as to improve the service life and improve the utilization. efficiency, improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

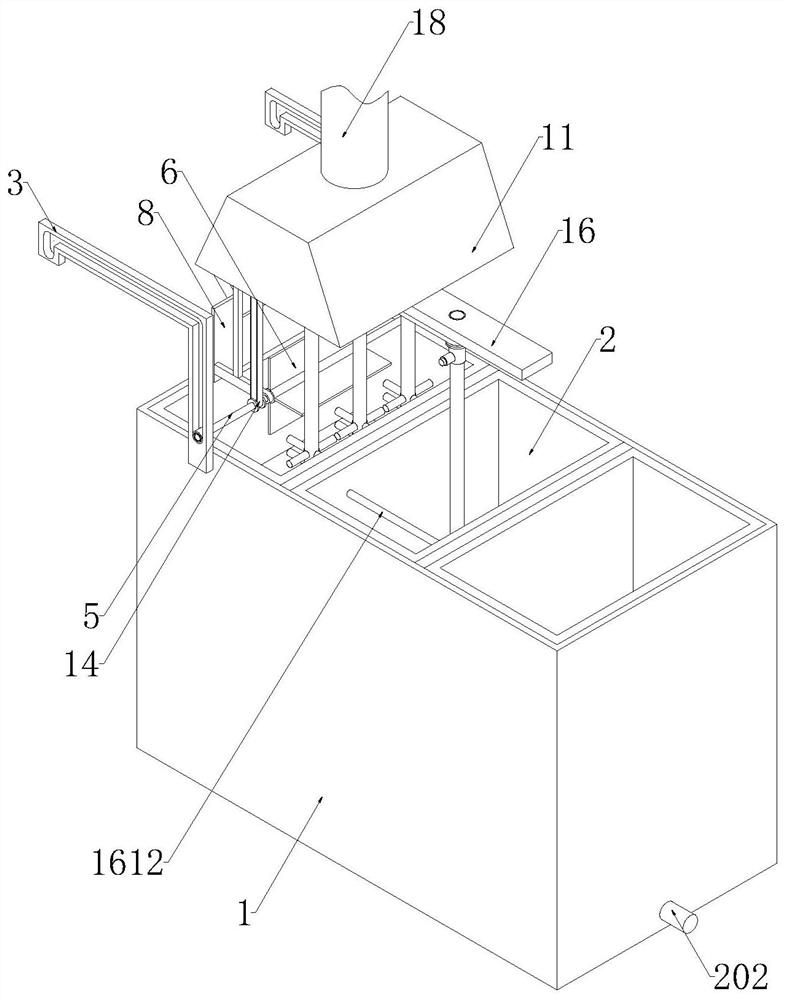

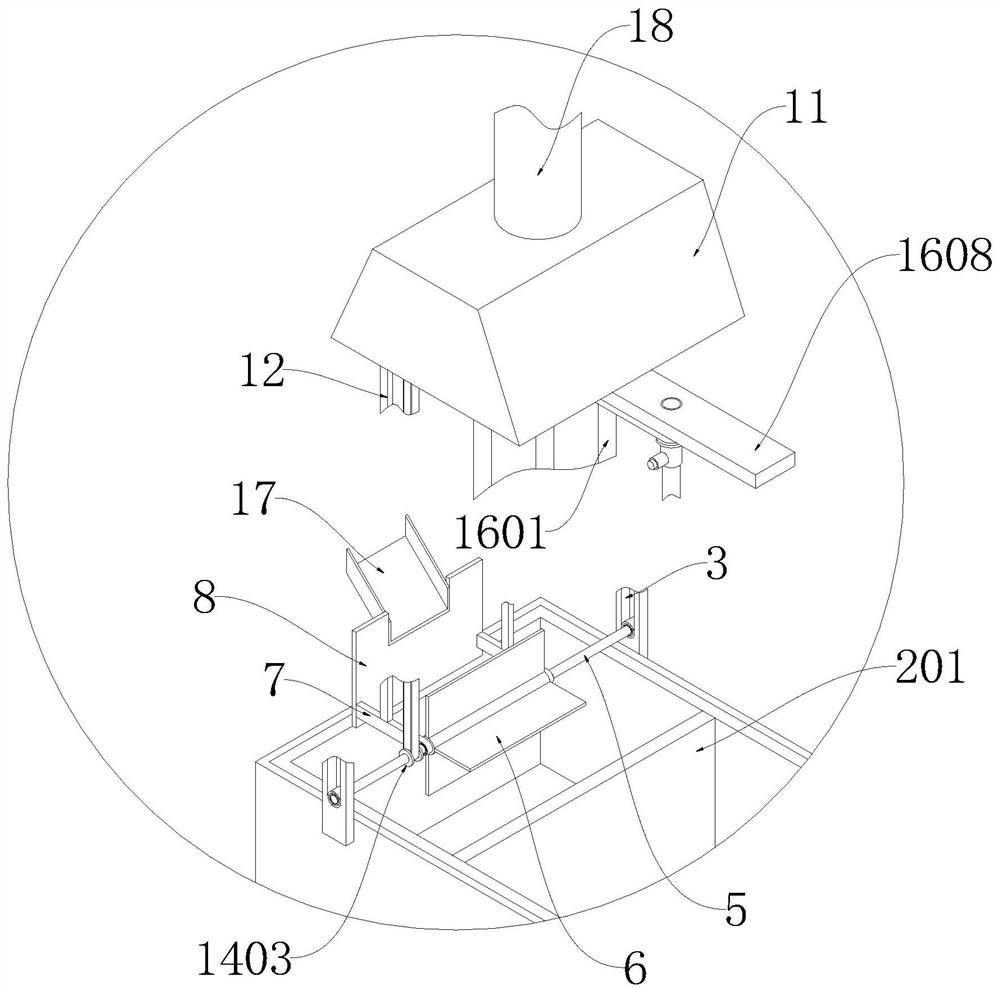

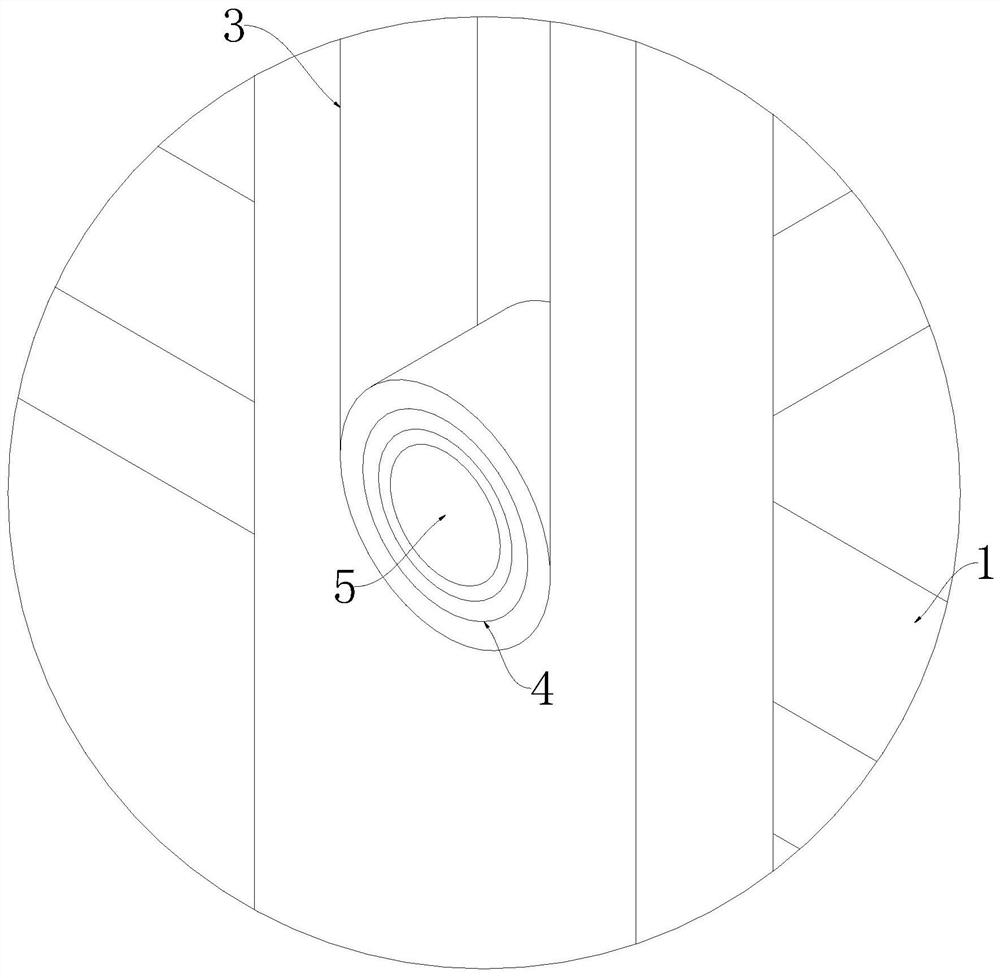

[0030] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, a filter system of the present invention for metal smelting blast furnace slag bottom filtration method includes a pool body 1, which is characterized in that a filter mechanism 2 is arranged in the pool body 1, and the filter mechanism 2 includes two first partitions 201, and Two first partitions 201 divide the interior of the pool body 1 from left to right into the first filter area, the second filter area and the third filter, and the tops of both sides of the pool body 1 are fixed with U-shaped pieces 3, And the U-shaped part 3 is facing the first filter area, and the U-shaped part 3 is provided with a U-shaped chute, and the first bearing 4 is slidably connected in the U-shaped chute, and the inner rings of the two first bearings 4 are fixedly arranged. There is a transmission rod 5, and the middle part of the transmission rod 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com