Nanofluidic device

A nanofluidic control and flow channel technology, applied in the field of in-situ experimental instruments, can solve the problems of tedious manual operation, switching and inconvenience of operators, and achieve the effect of improving user experience, convenient use and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

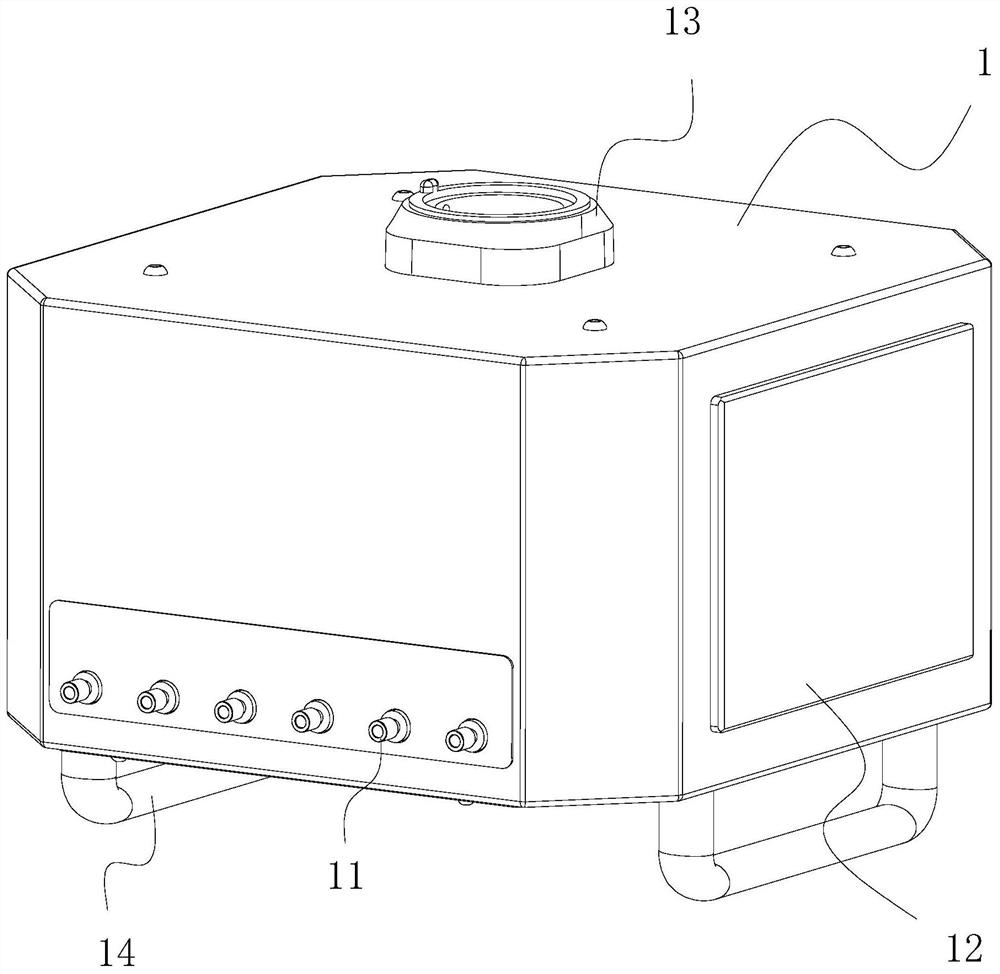

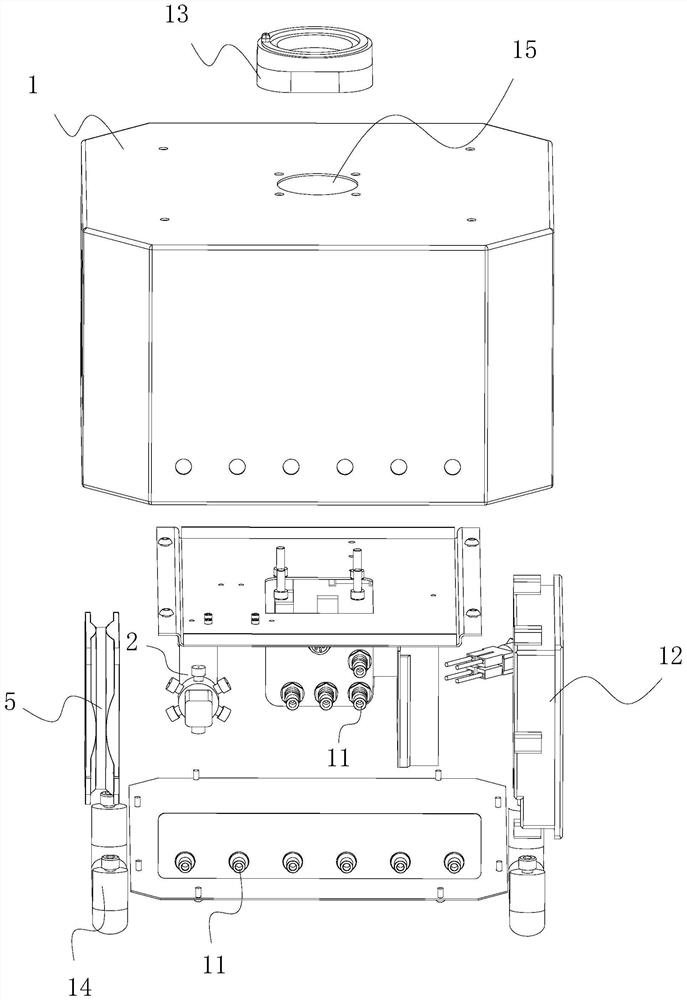

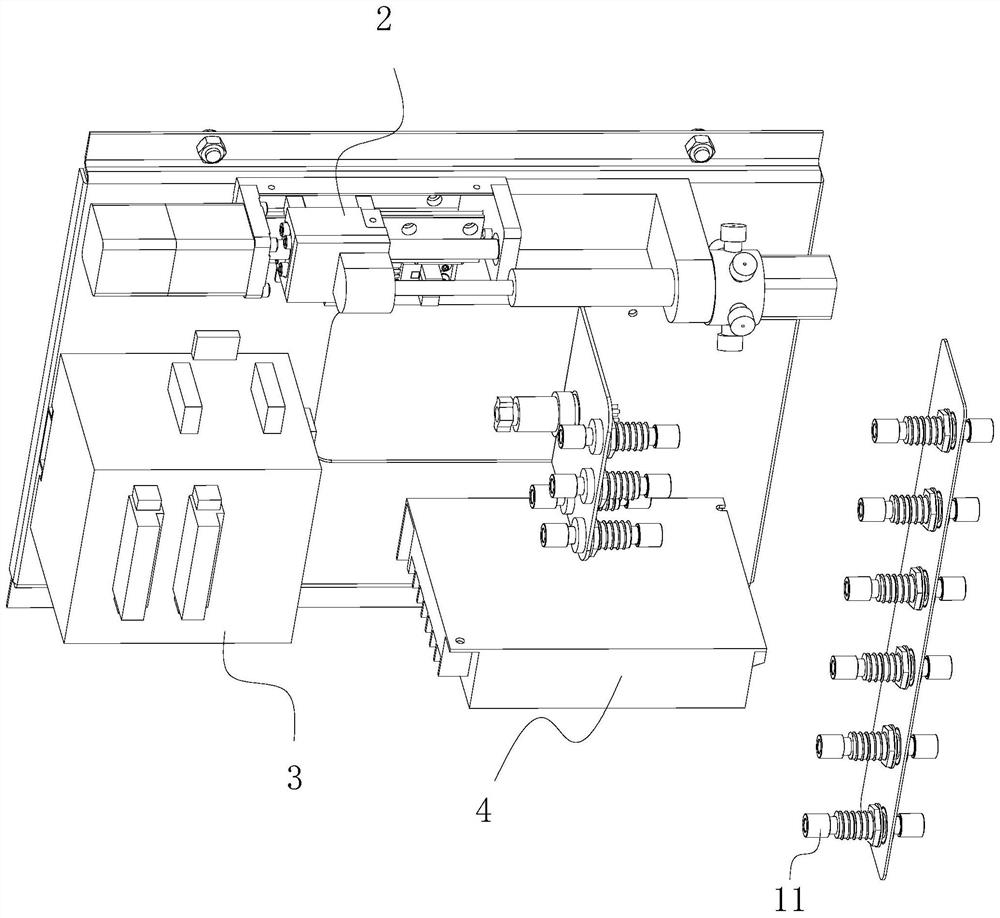

[0025] Such as Figures 1 to 5 As shown, a nanofluidic control device includes a casing 1 , a fluid control component 2 and a controller 3 are arranged inside the casing 1 , and the output terminal of the controller 3 is connected to the control input terminal of the fluid control component 2 . The controller 3 may be an existing PLC (Programmable Logic Controller, Programmable Logic Controller).

[0026] The fluid control assembly 2 has a flow channel switching valve 23 , a syringe 22 and a plurality of internal flow channel interfaces 21 . The channel switching valve 23 is used to switch the internal channel interface 21 communicating with the syringe 22: the internal rotation switching action of the channel switching valve 23 is controlled by the control signal provided by the controller 3, so that the fluid flows in from a specific internal channel interface 21 or flow out.

[0027] The casing 1 is provided with a plurality of external flow channel interfaces 11 , and di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com