Wood board paint spraying and drying device and working method thereof

A technology for wooden boards and drying devices, which is applied in the direction of spraying devices, liquid spraying devices, spray booths, etc., and can solve problems such as defects in the spraying of wooden boards, poor drying efficiency of wooden boards, and easy contamination of dust and impurities. Effect of increasing clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

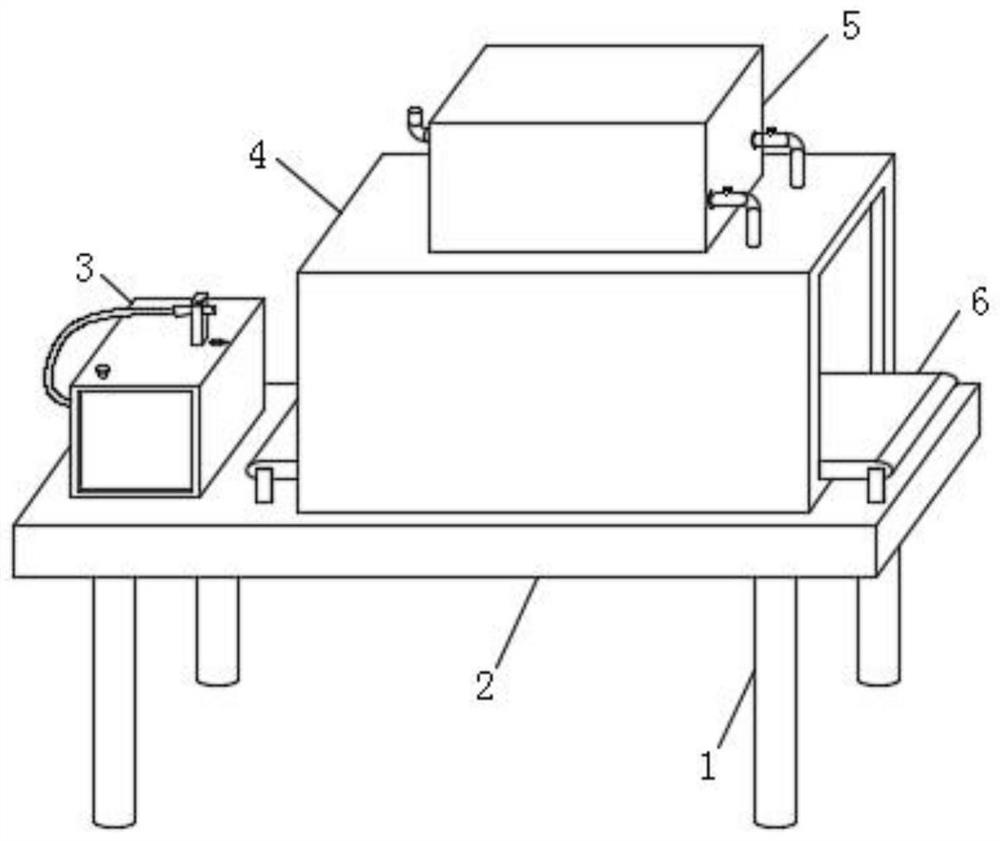

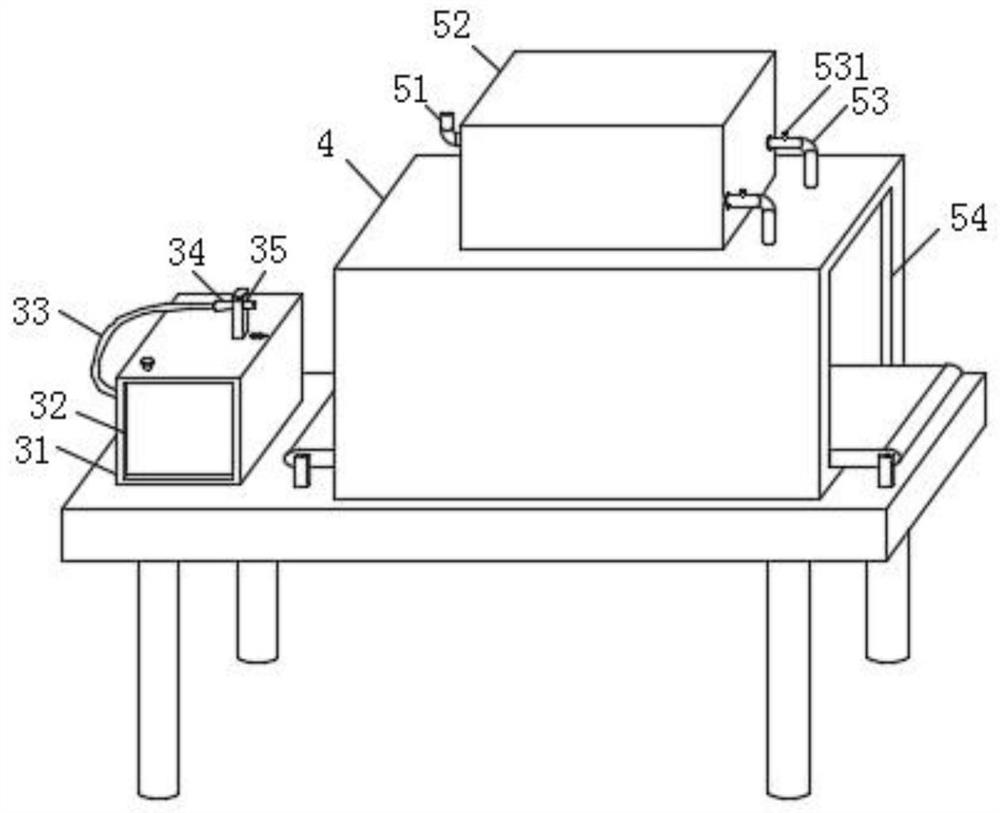

[0034] see Figure 1-7 As shown, a wooden panel paint spraying and drying device includes a support leg 1, a base plate 2, a paint spraying assembly 3, a drying box 4, a drying assembly 5 and a conveyor 6. One side of the upper end is provided with a painting assembly 3, and the other side of the upper end of the bottom plate 2 is provided with a drying box 4, and the upper side of the drying box 4 is provided with a drying assembly 5, and a conveyor 6 is installed inside the drying box 4;

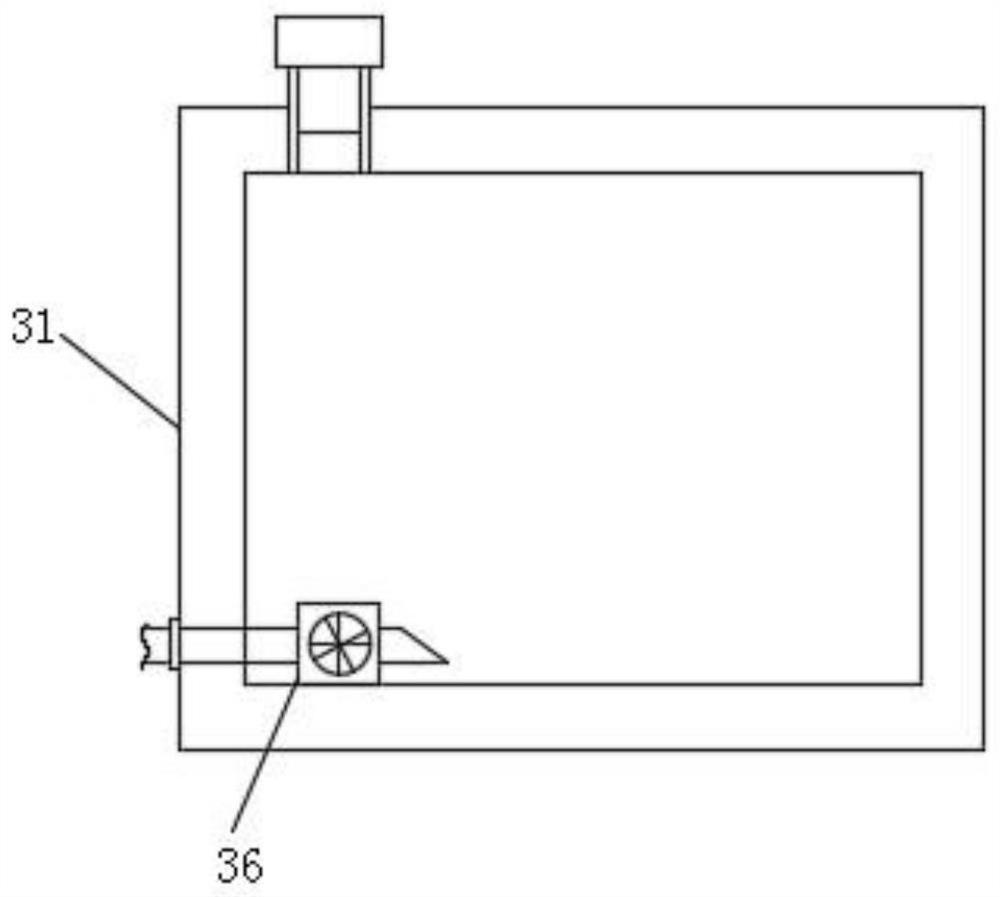

[0035] The paint spray assembly 3 includes a paint storage box 31, an observation mirror 32, a delivery pipe 33, a paint spray head 34, a placement plate 35, a cylindrical hole 351, a placement hole 352, a delivery pump 36, a clamping plate 37, a pulling block 38 and a pulling rod 39 A paint storage box 31 is installed on one side of the upper end surface of the bottom plate 2, and an observation mirror 32 is installed on one side of the paint storage box 31. A delivery pump 36 is installe...

Embodiment 2

[0043] A working method for spraying and drying wooden boards. The working method for spraying and drying wooden boards includes the following specific steps:

[0044] Step 1, open the sealing plug, the paint spray liquid enters the paint storage box 31 through the feed pipe for storage, and the staff checks the capacity of the paint spray liquid through the observation mirror 32. 391 is compressed by force, and the pulling rod 39 moves upward along the cylindrical hole 351. At this time, the clamping plate 37 is separated from the spraying head 34, and the worker takes out the spraying head 34 from the placement hole 352, and the spraying head 34 faces the wooden surface that needs to be painted. Plate, delivery pump 36 is energized to work, and the paint spray liquid inside the paint storage box 31 is transferred to the paint spray head 34 through the delivery pipe 33, which can realize the spraying of wood panels. In the placement hole 352, the pulling block 38 is released,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com