Drying device for solid wood door sheet production

A drying device and door panel technology, which is applied to the surface coating liquid device, pretreatment surface, coating, etc., can solve the problems of single structure, uneven drying, low drying efficiency, etc., and achieve uniform distribution, Guaranteed drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

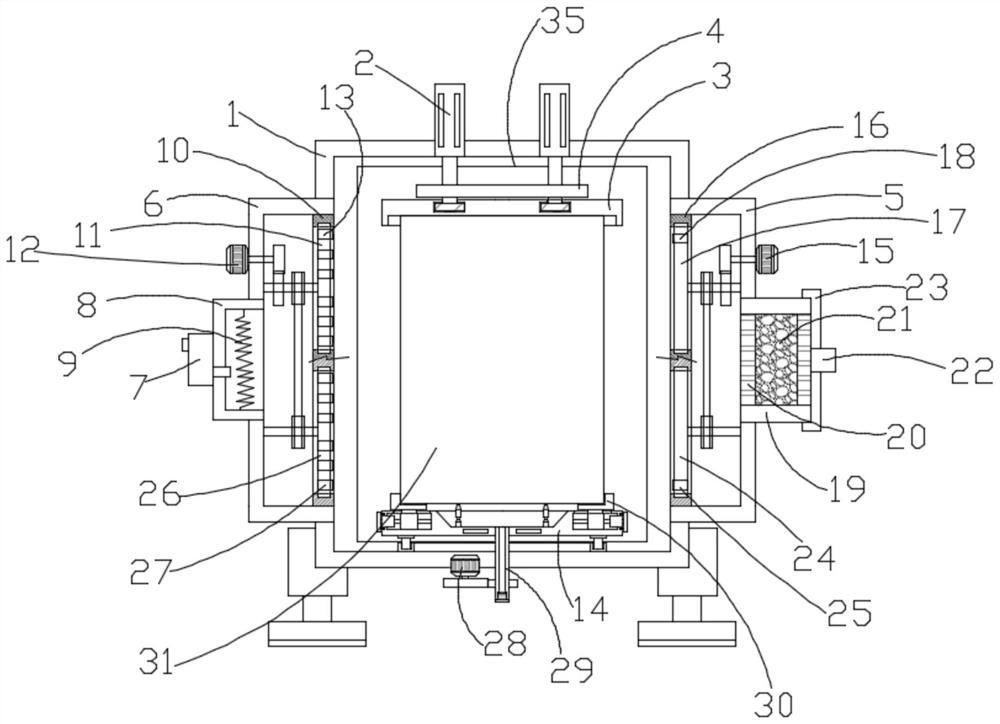

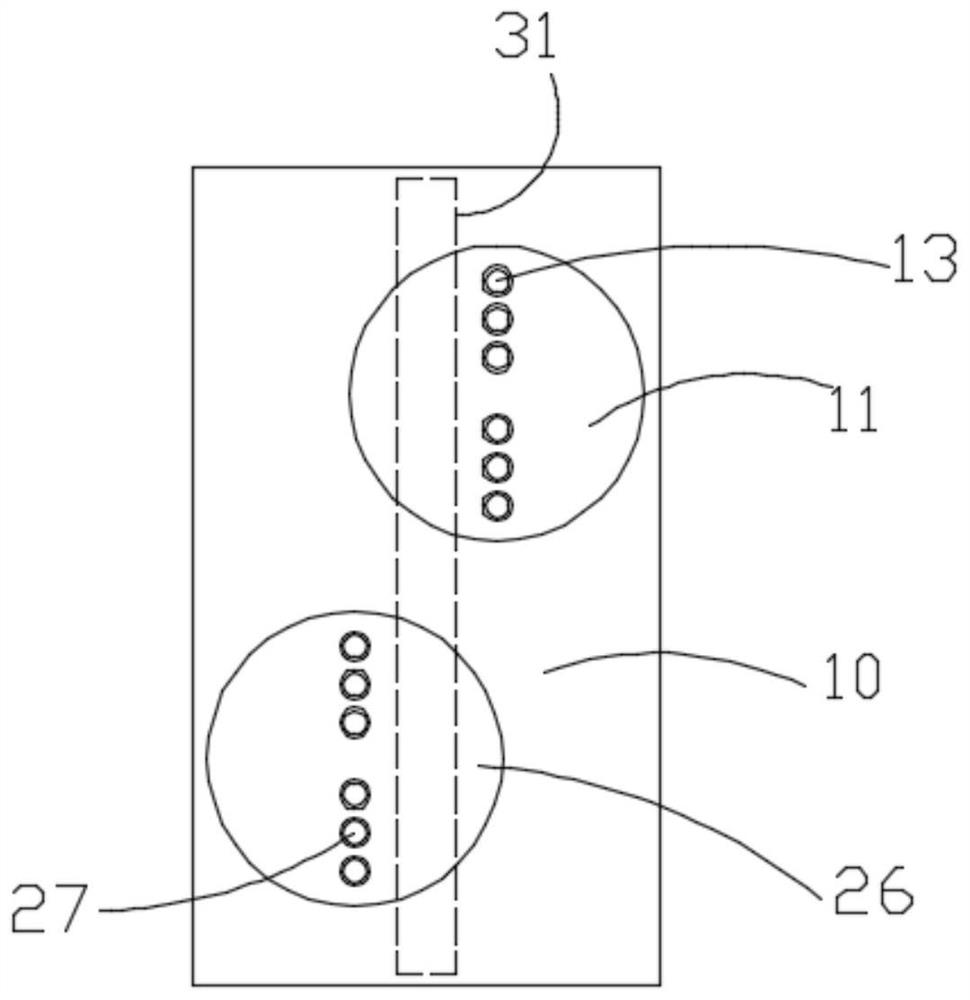

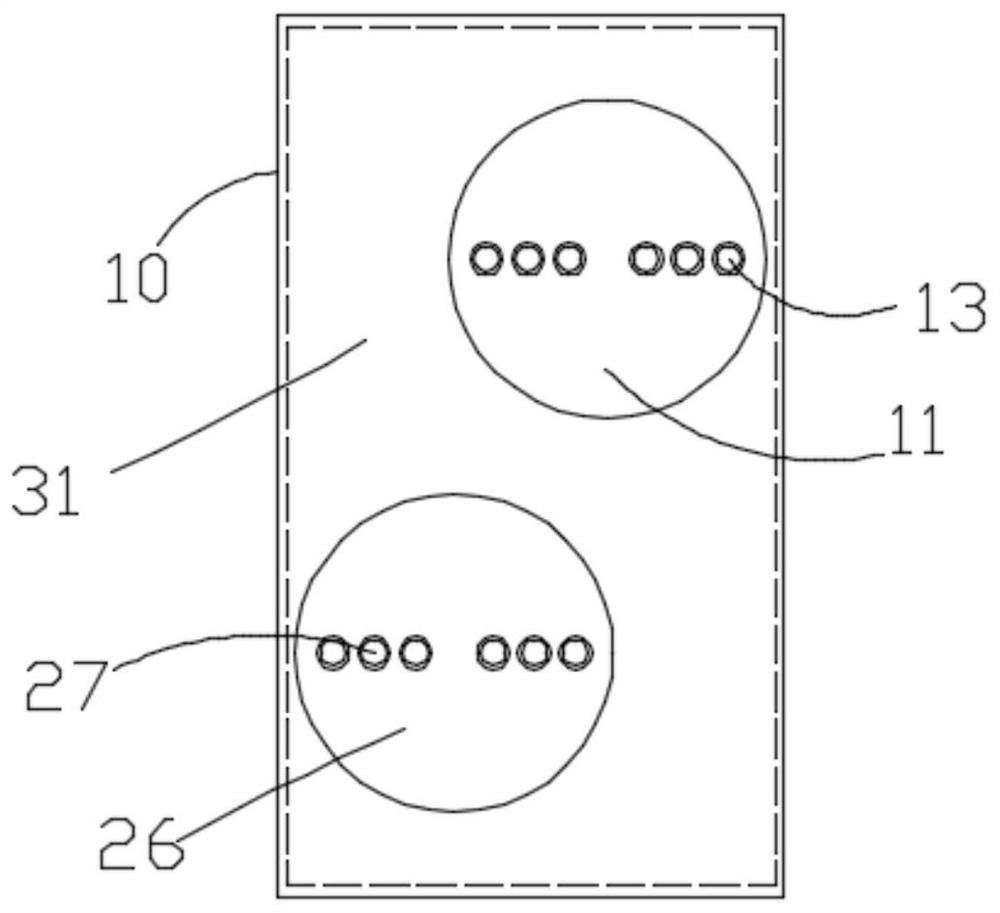

[0038] Such as figure 1 As shown, in a preferred embodiment provided by the present invention, a drying device for the production of solid wood door panels includes a drying box 1, the bottom of the drying box 1 is rotatably provided with a support mechanism, and the drying box 1 The inner top is provided with a compression mechanism corresponding to the support mechanism. After the bottom of the door panel 31 is placed on the support mechanism, the door panel 31 is compressed and fixed by the compression mechanism, so that the door panel 31 maintains a vertical state. When the mechanism rotates, it can drive the door panel 31 to rotate.

[0039] Further, in the embodiment of the present invention, one side of the drying box 1 is provided with a hot air blowing mechanism, and the other side of the drying box 1 is provided with an exhaust mechanism. Cooperating with each other, a flowing hot air flow can be formed in the drying box 1, and then the door panel 31 can be fully dr...

Embodiment 2

[0042] Such as figure 1 , Figure 5 , Figure 6 and Figure 7 As shown, different from Example 1, in another preferred embodiment provided by the present invention, the support mechanism includes a hollow tube 29 rotatably arranged on the bottom plate of the drying box 1, and the drying The bottom surface of the box 1 is provided with a third motor 28 for driving the hollow tube 29 to rotate. Preferably, the output shaft of the third motor 28 is connected to the hollow tube 29 through gear engagement.

[0043] Further, in the preferred embodiment provided by the present invention, the support mechanism also includes a support base 14 coaxially fixed on the top end of the hollow tube 29, and the support base 14 supports and rotates on the drying The inner bottom of the box 1; both sides of the support seat 14 along its length direction are provided with supporting parts, and the two supporting parts support the two corners of the bottom end of the door panel 31 respectively....

Embodiment 3

[0048] read on figure 1 , Figure 5 , Figure 8 and Figure 9 , different from Embodiment 2, in the preferred embodiment provided by the present invention, the surface of the door panel 31 is painted by a paint spraying mechanism (not shown in the figure) arranged in the drying box 1, and the rotation of the door panel 31 is coordinated. , the surface of the door panel 31 can be evenly sprayed, it can be understood that this embodiment does not describe the spraying mechanism, and those skilled in the art can set a suitable painting mechanism in the drying box 1 according to conventional technical means, such as The inner wall of the front side plate of the drying box 1 is provided with a paint spraying mechanism. The paint spraying mechanism can apply for a paint liquid pump and a paint spray nozzle connected with the paint liquid pump. Provide paint liquid; the above-mentioned paint liquid pump, paint spray nozzle and paint liquid tank all belong to those skilled in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com