Split primary collimator

A split-type, collimator technology, applied in the direction of using diaphragm/collimator, etc., can solve the problem of unsolved shielding, increase the difficulty of alignment, affect the shielding effect, etc., to meet the support, save production materials, The effect of increasing the shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

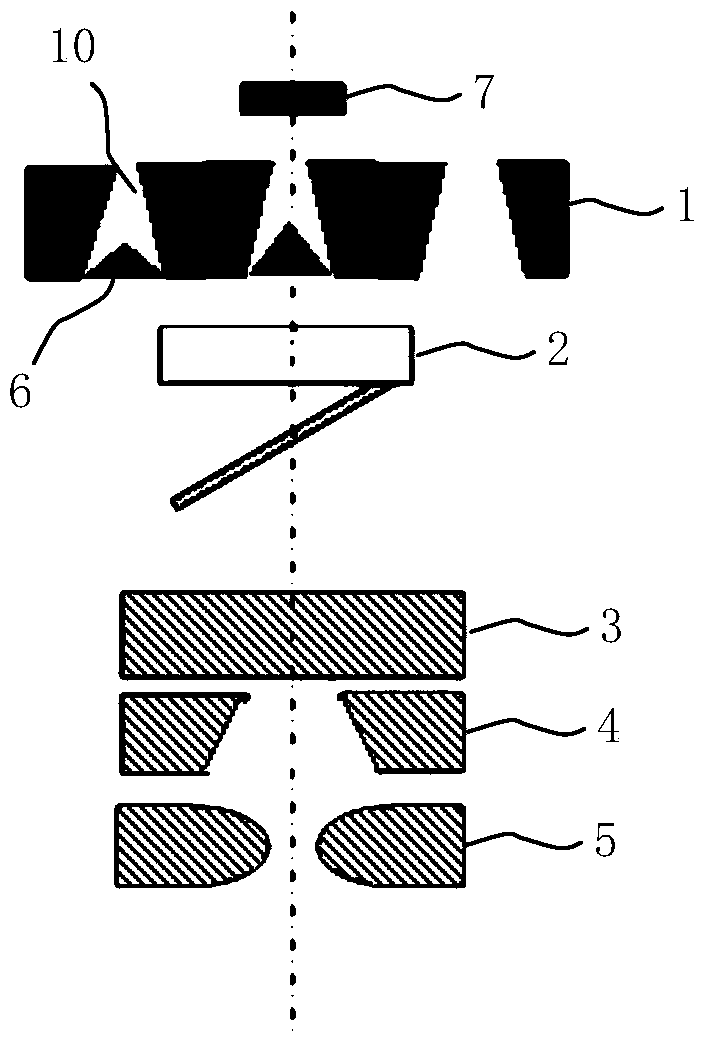

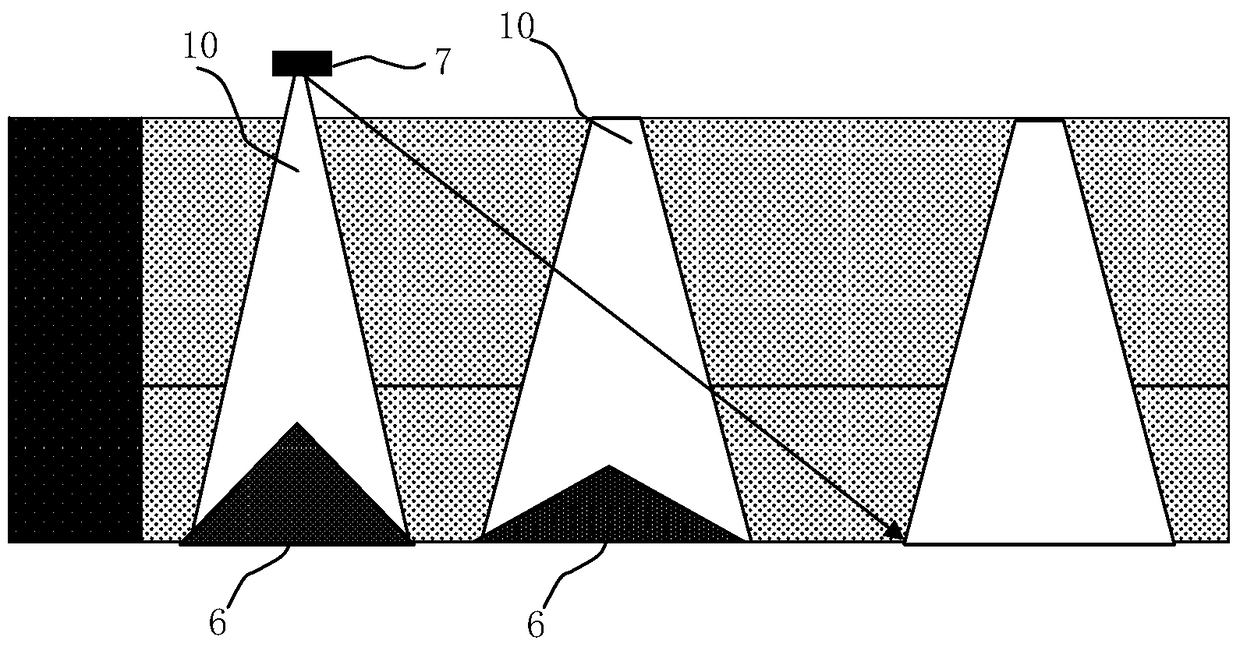

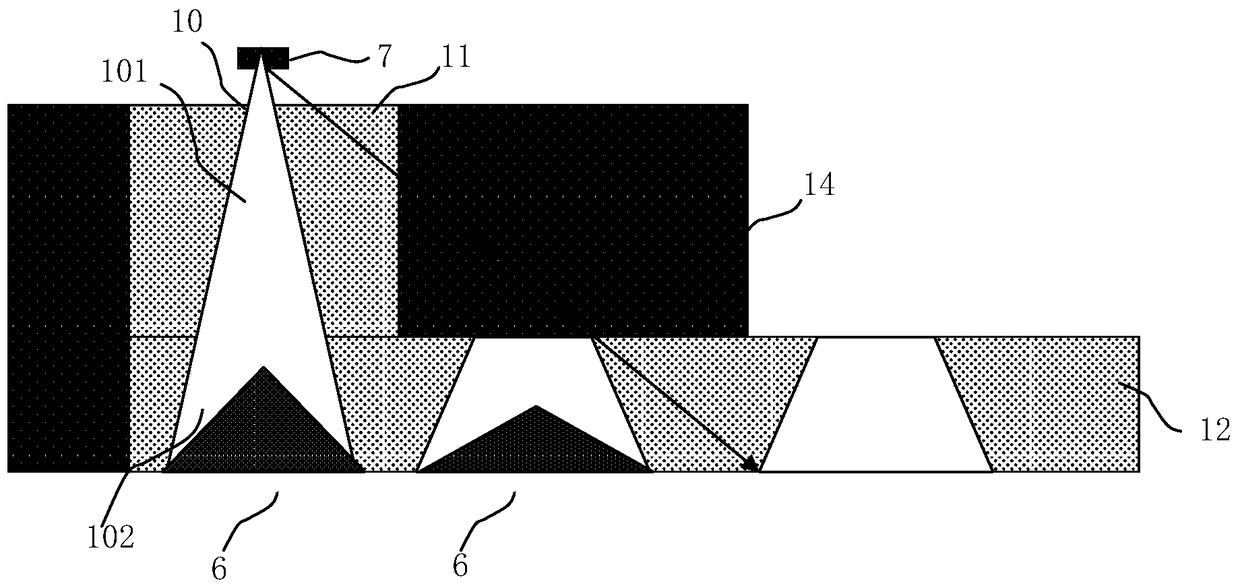

[0033] image 3 It is a schematic diagram of the split primary collimator structure and ray path of the present invention.

[0034] See image 3 , the split primary collimator provided by the present invention separates the upper half of the primary collimator from the lower half, and divides it into a fixed part 11 with a first through hole 101 and a movable part with a plurality of second through holes 102 part 12, the second through hole 102 is an empty hole or is provided with a leveler 6; The first through hole 101 and the second through hole 102 are matched, and combined to form a beam limiting hole 10 for the radiation beam to pass through. Preferably, both the first through hole 101 and the second through hole 102 are conical holes, and the first through hole 101 and the second through hole 102 are matched and combined to form the conical bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com