Ultrasonic cleaning device with pre-cleaning function

A cleaning device, ultrasonic technology, applied in the field of ultrasonic cleaning, can solve the problems of reducing the number of times of use, increasing the time of cleaning, increasing the cost of cleaning, etc., to achieve the effect of reducing cleaning costs, increasing the number of times of use, and reducing dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

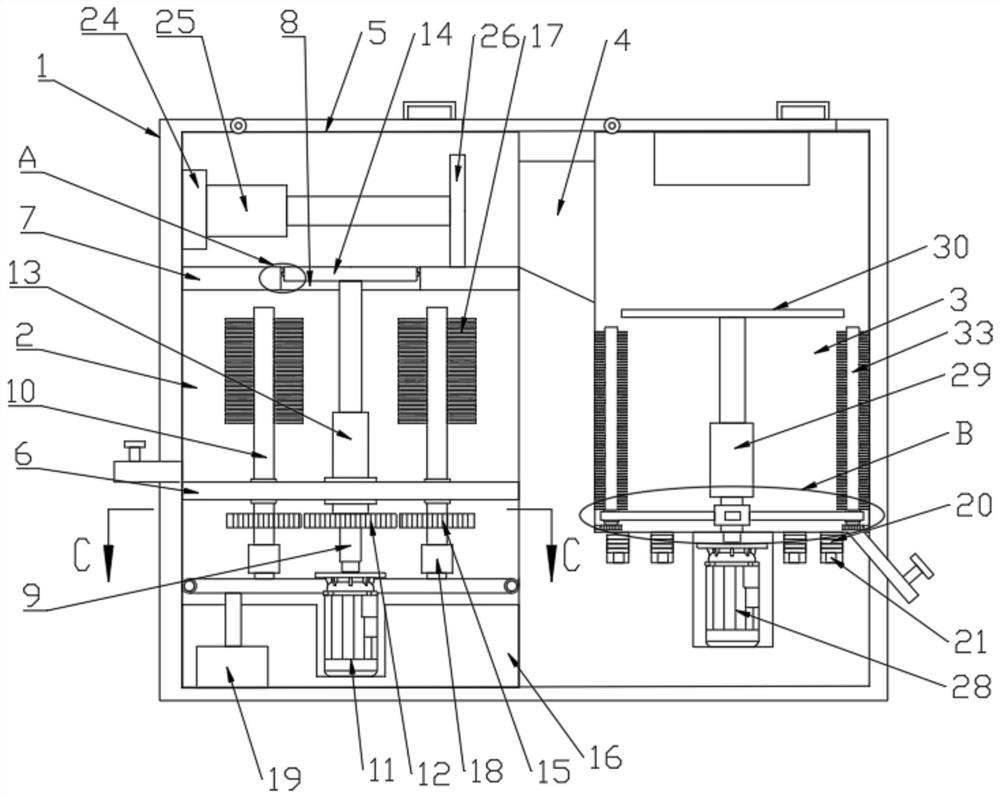

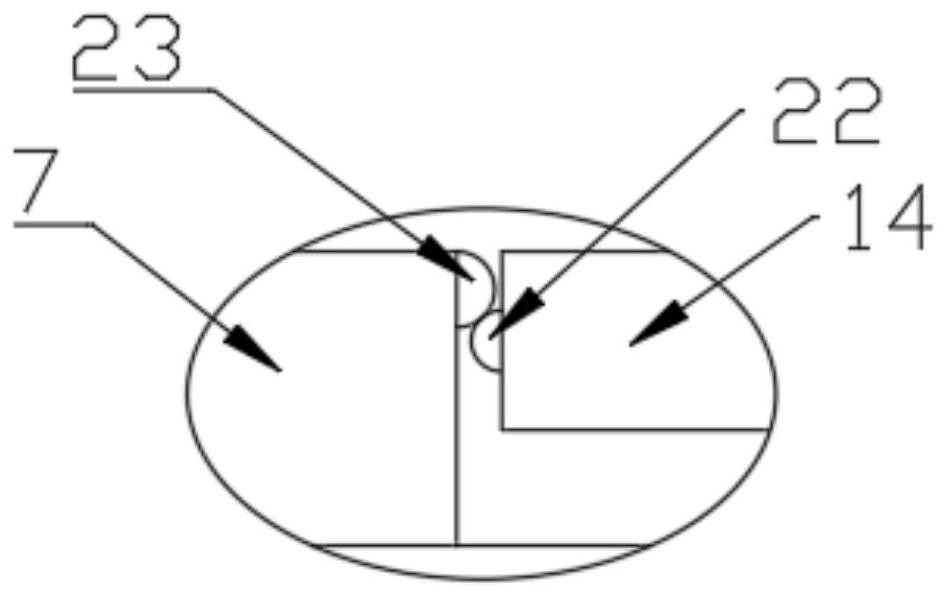

[0026] see Figure 1-7 , an ultrasonic cleaning device with a pre-cleaning function, including a cleaning box 1, a first cleaning cabin 2 and a second cleaning cabin 3 are arranged in the cleaning box 1, and the first cleaning cabin 2 and the second cleaning cabin 3 are provided with water outlets at the bottom of the side, and the top of the side of the first cleaning chamber 2 close to the second cleaning chamber 3 is provided with a through hole 4, and the top surface of the cleaning box 1 is located between the first cleaning chamber 2 and the second cleaning chamber. 3 positions are hingedly provided with a box cover 5, the first cleaning compartment 2 is provided with a first partition 6, and the first cleaning compartment 2 is fixedly provided with a second partition 7 above the first partition 6, The second dividing plate 7 is provided with a placement hole 8, and the top surface of the second dividing plate 7 is at the same horizontal position as the bottom of the thr...

Embodiment 2

[0032] This embodiment has been improved on the basis of Embodiment 1, specifically:

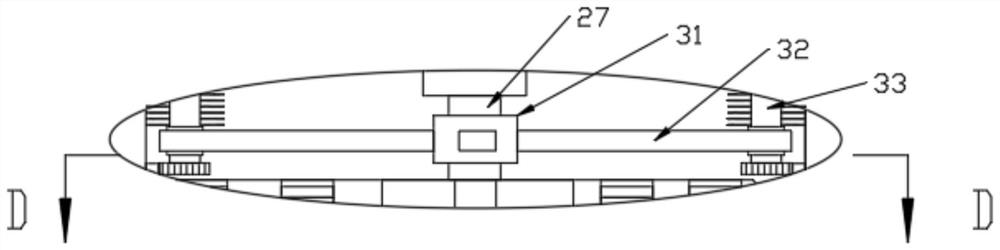

[0033] A cleaning mechanism is also provided in the second cleaning chamber 3, and the cleaning mechanism includes a third rotating shaft 27. The third rotating shaft 27 is sealed and rotationally connected with the bottom surface of the second cleaning chamber 3, and the third rotating shaft 27 is arranged in the box. Driven by the second motor 28, the top of the third rotating shaft 27 is connected with the loading plate 30 through the third telescopic rod 29, and the outer wall of the third rotating shaft 27 is fixedly provided with a rotating block 31, and the outer wall of the rotating block 31 is fixed A connecting plate 32 is provided, the end of the connecting plate 32 is rotatably connected with a cleaning rod 33, the cleaning rod 33 is uniformly provided with cleaning brushes 17, and the cleaning rod 33 is fixedly sleeved with a third gear 34, the The inner wall of the second clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com