Drilling equipment for intelligent aluminum alloy window frame production

A technology of drilling equipment and aluminum alloy, applied in drilling/drilling equipment, metal processing equipment, boring/drilling, etc. The effect of mass rapid production jobs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

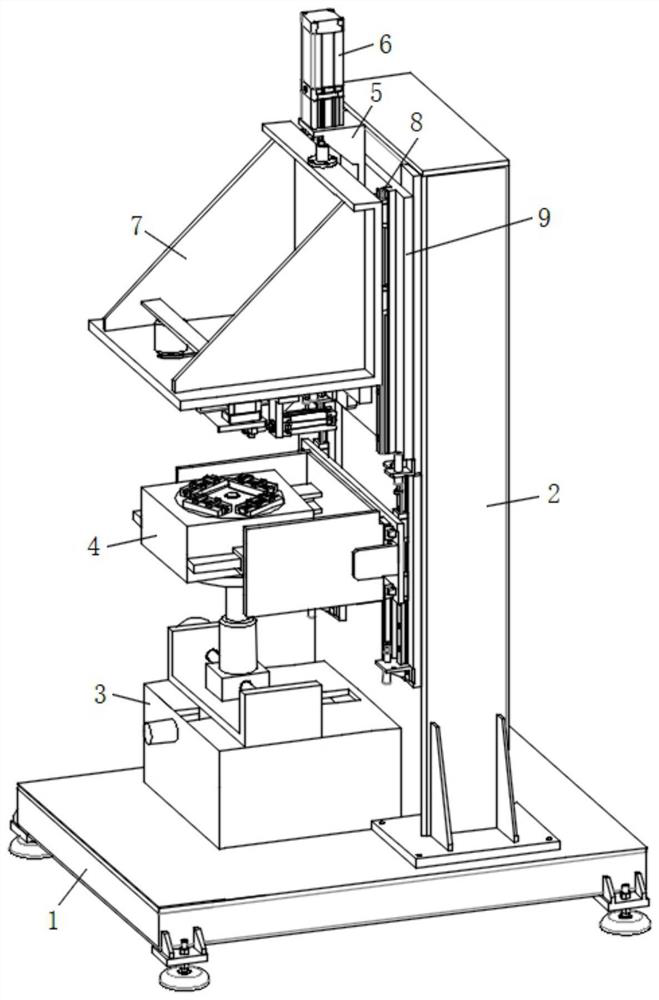

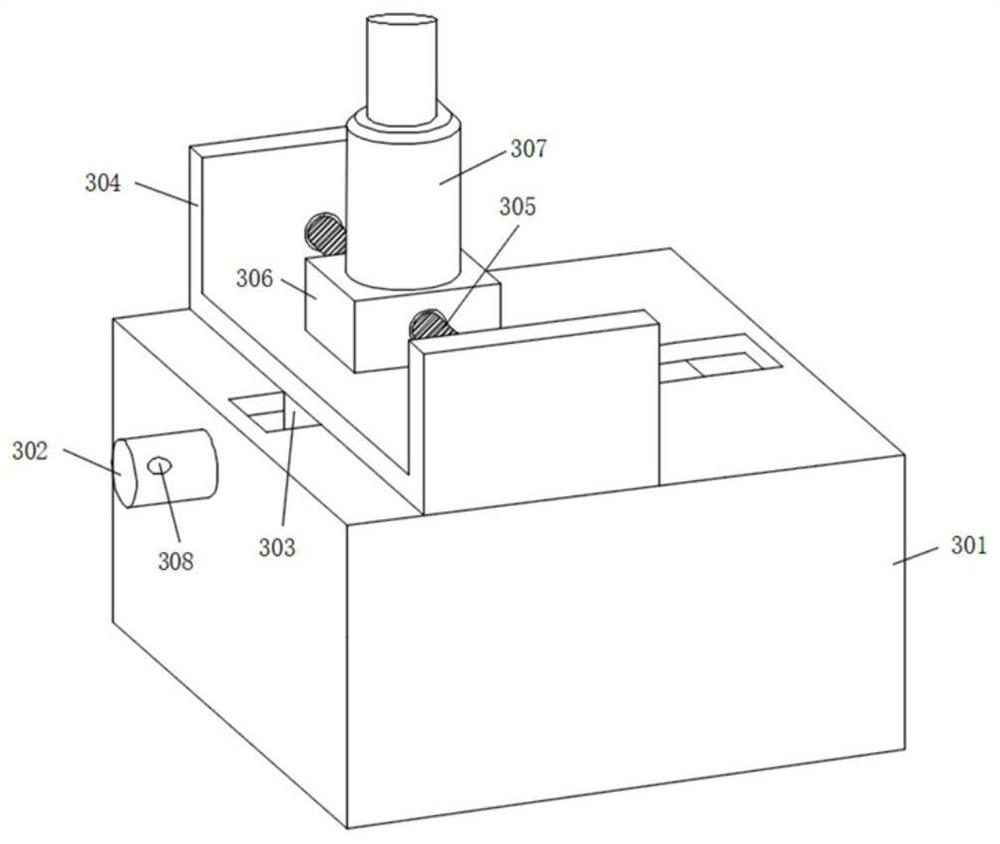

[0030] refer to Figure 1-5 , a kind of drilling equipment for the production of intelligent aluminum alloy window frames, including a base 1, a support seat 2 is welded on the rear side of the top surface of the base 1, a driving mechanism 3 is arranged in the middle of the top surface of the base 1, and the driving mechanism 3 includes a mounting seat 301. The middle part of the top surface of the seat 301 is also provided with a rectangular groove, the front and rear inner walls of the rectangular groove are rotatably connected with a screw mandrel 302, the outer wall of the screw mandrel 302 is screwed with a sliding block 303, and the top surface of the sliding block 303 is fixedly connected with a U-shaped frame by screws 304, the inner wall on both sides of the U-shaped frame 304 is rotatably connected with screw mandrel 2 305, the outer wall of screw mandrel 2 305 is fixedly connected with mounting block 306 by threads, and the top surface of mounting block 306 is fixed...

Embodiment 2

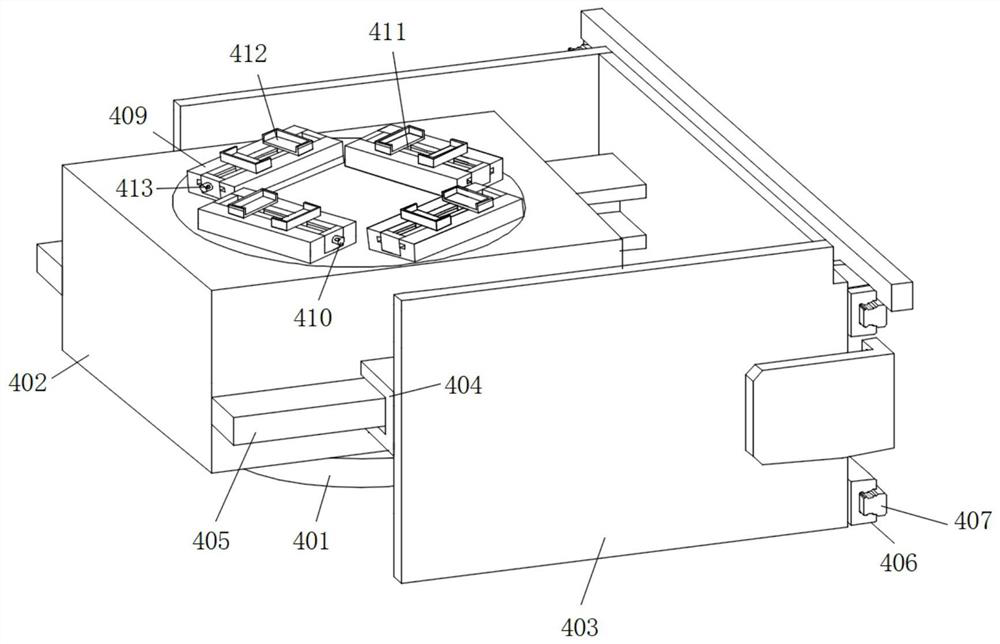

[0033] Such as figure 1 and 5 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the mounting dish 701 is fixedly connected to the output end of the cylinder 26 by screws, and both sides of the inner bottom surface of the mounting dish 701 are welded with protective plates 702. Two protective plates 702 There is also a horizontal plate 703 fixedly connected between them, and a driver 704 is also rotatably connected to the bottom surface of the mounting dish 701. The output ends of the driver 704 are all fixed with a drill bit 706 through a coupling 705. The specifications of the drill bits 706 are all inconsistent. Rotating rods 707 are fixedly connected to the stationary cylinders, and two adjacent rotating rods 707 are rotated and connected by conveyor belts 708. One side of the bottom surface of the horizontal plate 703 is also fixedly connected with a servo motor 709 by screws, and the output of the servo motor 709 The end is fixedly connected wi...

Embodiment 3

[0036] Such as figure 1 and 5 As shown, this embodiment is basically the same as Embodiment 2. Preferably, there are multiple driving elements 704 and they are evenly distributed on the bottom surface of the mounting dish 701 .

[0037] In this embodiment, a plurality of driving parts 704 are provided and evenly distributed on the bottom surface of the installation dish 701, so as to facilitate the installation of drill bits 706 of different specifications, thereby meeting the requirements for drilling aluminum alloy window frames.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com