Circuit board welding device

A technology for welding devices and circuit boards, which is applied in the direction of electric heating devices, auxiliary devices, welding equipment, etc., can solve the problems of uncoiled cables, etc., and achieve the effects of easy lifting, reduced damage, and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

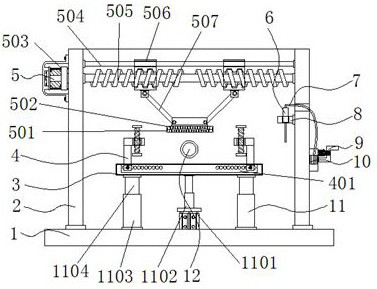

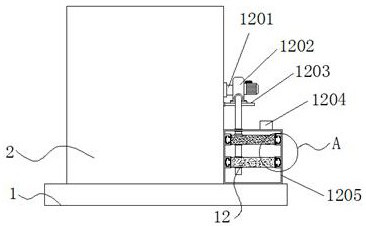

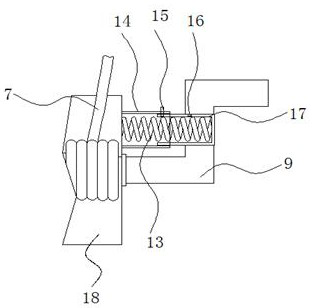

[0035] Example 1: See Figure 1-6 , a circuit board welding device, comprising a base plate 1 and a support frame 2, the two sides and one end of the top of the base plate 1 are respectively fixedly connected with the support frame 2, the top of one side of the support frame 2 is provided with a preheating mechanism 5, the top of the base plate 1 A workbench 3 is provided, a limit structure 4 is provided on both sides of the top of the workbench 3, a lifting mechanism 11 is provided between the bottom plate 1 and the support frame 2, and a support block 8 is fixedly connected to one side of the support frame 2, and the support block 8 The interior of the welding head 6 is provided with a cable 7 fixedly connected to the top of the welding head 6, one end of the support frame 2 is provided with a purification mechanism 12, and one side of the support frame 2 is provided with a winding structure;

[0036] see Figure 1-6 , a circuit board welding device also includes a winding ...

Embodiment 2

[0039] Embodiment 2: The limit structure 4 is composed of a chute 401, a limit hole 402, a limit plate 403, a spiral groove 404, a screw rod 405, a support rod 406, a limit bolt 407 and a slider 408, and the chute 401 is fixedly connected Inside the workbench 3, the support rod 406 is arranged on both sides of the top of the workbench 3, and the inside of one side of the support rod 406 is fixedly connected with a spiral groove 404, and the inside of the spiral groove 404 is provided with a screw rod 405, and the bottom of the screw rod 405 The end is fixedly connected with the limit plate 403, the bottom end of the support rod 406 is fixedly connected with a slider 408, the inside of the slider 408 is fixedly connected with the limit hole 402, and the inside of the limit hole 402 is provided with a limit bolt 407;

[0040] The limiting holes 402 are respectively fixedly connected to the inside of the chute 401 and the slide block 408, the slide block 408 is arranged inside the...

Embodiment 3

[0042] Embodiment 3: The preheating mechanism 5 is composed of a preheating plate 501, a heating wire 502, a servo motor 503, a slide rod 504, a screw shaft 505, a screw sleeve 506, a limit rod 507, an installation block 508 and a connecting block 509. The servo motor 503 is arranged on the top of the other side of the support frame 2, the model of the servo motor 503 is SMG80-M02430, the output end of the servo motor 503 is provided with a screw shaft 505, and the top of the screw shaft 505 is provided with a slide bar 504, the slide bar 504 and The screw shaft 505 is sleeved with a screw sleeve 506, the bottom end of the screw sleeve 506 is fixedly connected with a mounting block 508, the bottom end of the mounting block 508 is provided with a connecting block 509, and the bottom end of the connecting block 509 is fixedly connected with a preheating plate 501 , the inside of the preheating plate 501 is provided with a heating wire 502, the model of the heating wire 502 is OCR...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com