A kind of ti alloy pipe fitting welding method and welding device

A pipe fitting welding and alloying technology, which is applied in the direction of welding equipment, welding equipment, auxiliary equipment, etc., can solve the problems of cracks in the heat-affected zone, poor weldability of titanium alloys, unfavorable continuous welding, etc., and achieve the effect of fast cutting and guaranteed welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

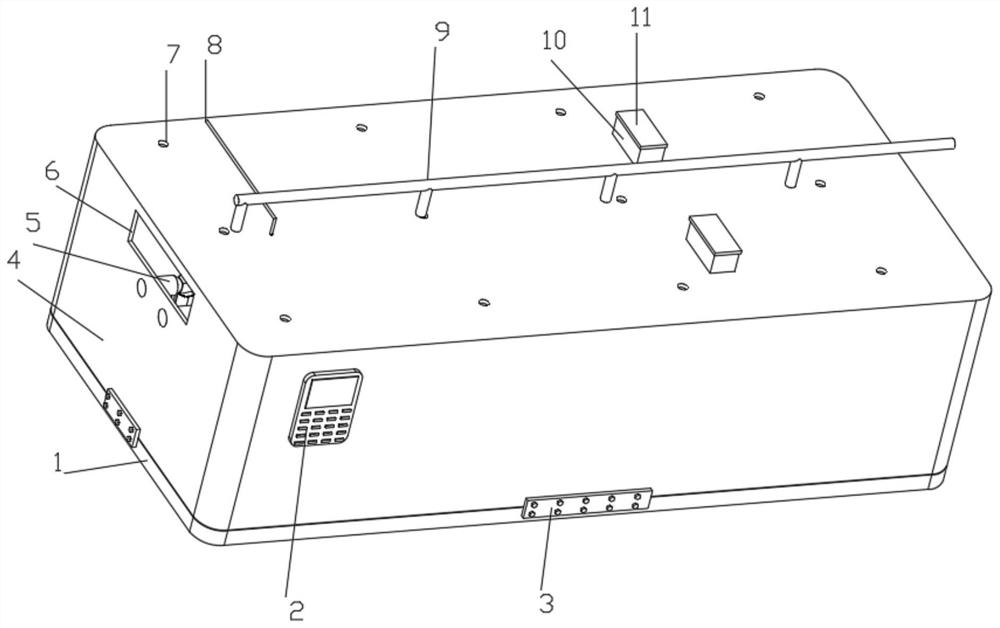

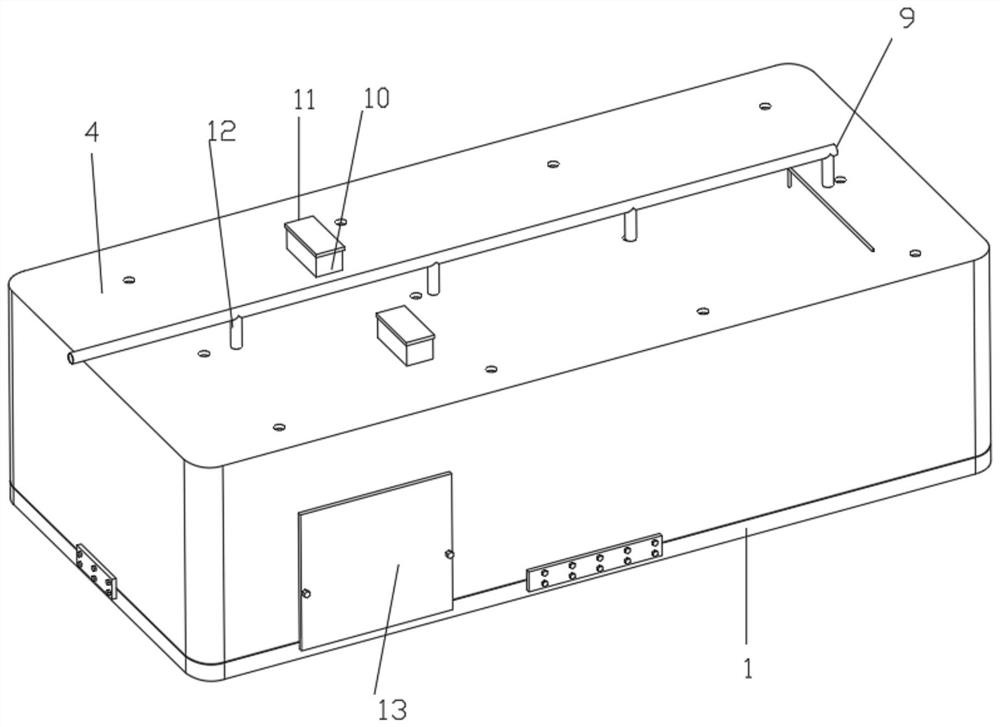

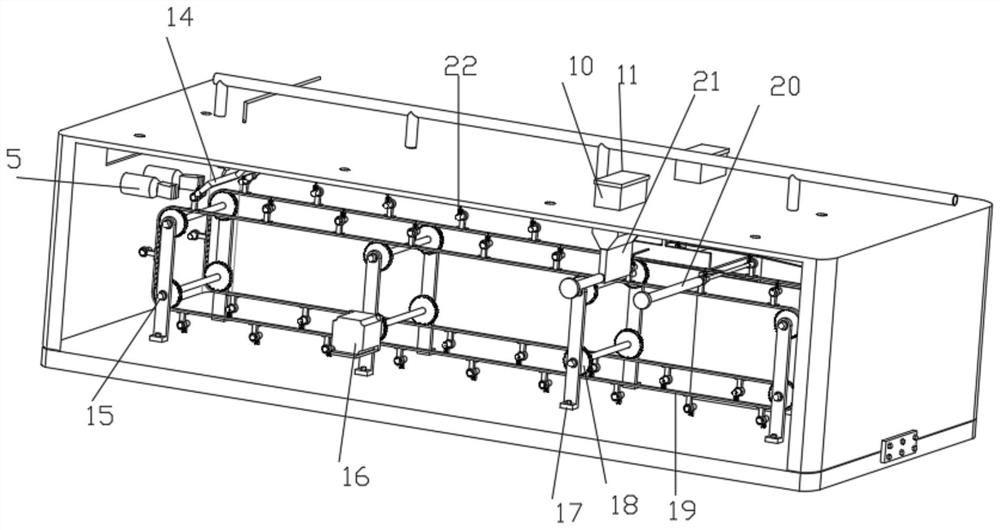

[0050] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 9, and 10 show a Ti alloy pipe welding device, including a base 1, a controller 2, a welding torch connection cable 8, a horizontal pipe 9, a gas injection pipe 12 and a welding torch 24, the base The top of 1 is connected with an intermittent moving structure for the intermittent movement of Ti alloy pipe fittings. The intermittent moving structure includes a rotating shaft 15, a stepping motor 16, a support plate 17, a ring gear 18, a chain 19, a fixed sleeve 22, a support block 36 and The one-way bearing 37, the support plate 17 is symmetrically and evenly fixed on the top of the base 1 by bolts, the upright position of the support plate 17 is connected with two groups of identical rotating shafts 15 through the connected bearings to rotate up and down, and the outer parts of one group of rotating shafts 15 end is fixedly connected with the output end of the stepper motor 16, and the stepper motor 16 is fixedly installed on the ...

Embodiment 2

[0058] Embodiment 2 is a further improvement to Embodiment 1.

[0059] Such as Figure 8 The shown fixing structure comprises an n-shaped plate 38, a straight plate 39, a round bar 40, a spring 41, an arc-shaped pressing plate 42 and a straight groove 43. The top of the n-shaped plate 38 is fixedly connected with an n-shaped plate 38, the straight hole of the n-shaped plate 38 is fitted and slidably connected with a straight plate 39, the inner wall of the straight plate 39 is fixedly connected with a round rod 40 for driving the straight plate 39 to move, and the bottom of the straight plate 39 is fixedly connected with a Arc-shaped pressing plate 42, the diameter of the bottom of the arc-shaped pressing plate 42 is the same as the diameter of the inner ring of the fixed sleeve 22, the top of the arc-shaped pressing plate 42 and the inner top of the n-shaped plate 38 are fixedly connected with a spring 41, and the spring 41 is sleeved on the straight plate On the outside of ...

Embodiment 3

[0061] Embodiment 3 is a further improvement to Embodiment 1.

[0062] Such as Figure 4 , 10As shown, the outer wall of the welding gap correction plate 26 is connected with a push structure for pushing the round rod 40 to move, the push structure includes an L-shaped support rod 27 and an oblique guide rod 28, and the right end of the L-shaped support rod 27 is fixedly connected with an oblique guide When the right end of the rod 28 and the oblique guide rod 28 contact the round rod 40, the oblique guide rod 28 pushes the round rod 40 to move upwards and move the Ti alloy pipe to the L-shaped support rod 27, and the right end of the L-shaped support rod 27 is arranged on the first electric motor. The right end of the push rod 20, the left end of the L-shaped support rod 27 is located at the left end of the third electric push rod 31, when the round rod 40 contacts the L-shaped support rod 27, the arc-shaped pressing plate 42 is separated from the Ti alloy pipe fitting, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com