Production process of high-wear-resistance antibacterial fabric

A technology of antibacterial fabric and production process, which is applied in the field of production process of high wear-resistant antibacterial fabric, can solve the problems of short antibacterial effect, decline of antibacterial effect of fabric, not enough environmental protection and health, etc., and achieve the effect of improving antibacterial effect and short antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

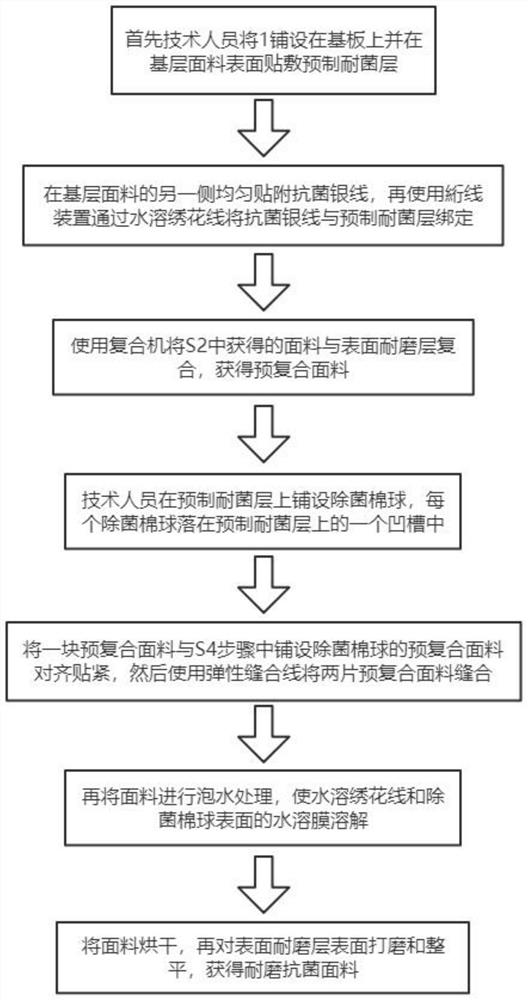

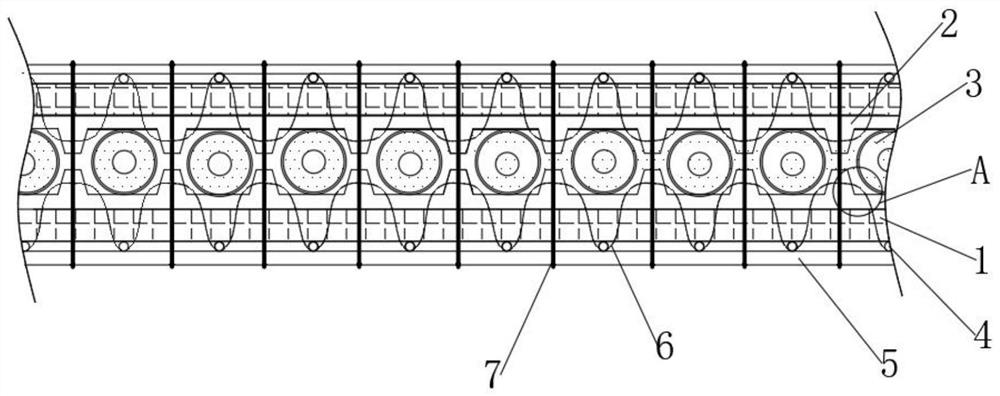

[0045] see Figure 1-2 , a production process of high wear-resistant and antibacterial fabrics, the specific process is:

[0046]S1, first the technician lays 1 on the substrate and sticks the prefabricated antibacterial layer 2 on the surface of the base fabric 1;

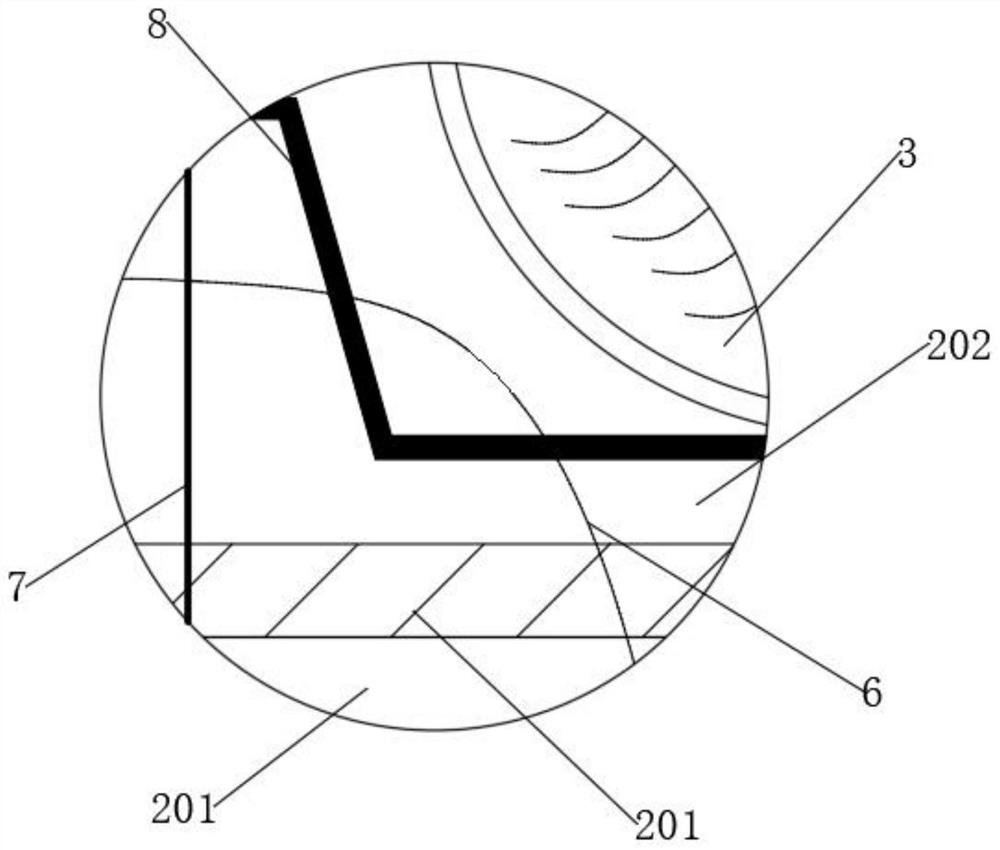

[0047] S2, attach antibacterial silver thread 4 evenly on the other side of base fabric 1, use water-soluble resin glue to bond when attaching, silver thread 4 is located at the center of the groove on the prefabricated antibacterial layer 2, and then use quilting device The antibacterial silver thread 4 is bound to the prefabricated antibacterial layer 2 through the water-soluble embroidery thread 6. When the water-soluble embroidery thread 6 is quilting, the water-soluble embroidery thread 6 will bind and fix the antibacterial silver thread 4 on the base fabric 1, and the water-soluble embroidery thread 6 Sequentially penetrate two adjacent grooves on the prefabricated antibacterial layer 2, so that after the w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com