Composite heat-preservation steel-reinforced concrete integrated building structure and construction technology

A steel-reinforced concrete and composite thermal insulation technology, applied in building components, building structures, buildings, etc., can solve problems such as difficulty in meeting high-strength requirements of building structures, inability to guarantee wall panels and structural beams, and strong mechanical connection effects. To achieve the effect of enhancing the heat insulation effect, enhancing the overall heat insulation performance, and enhancing the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

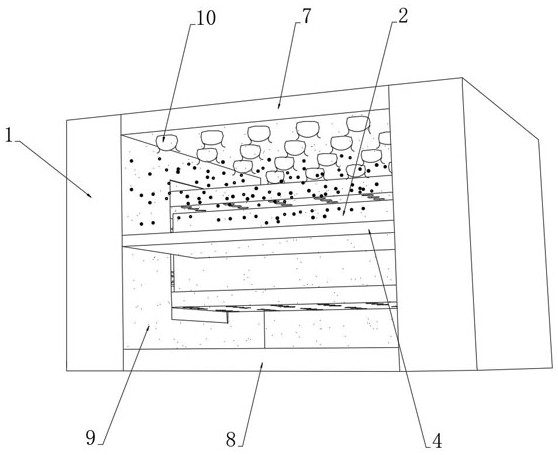

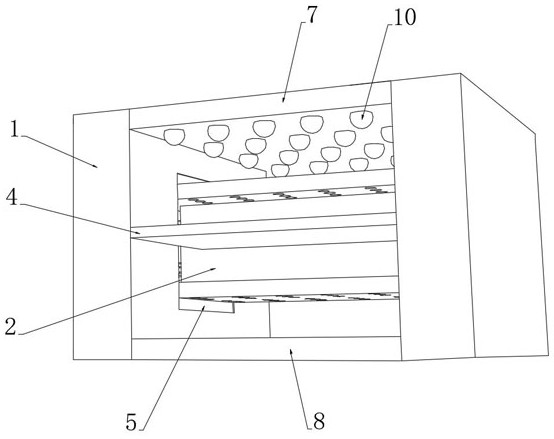

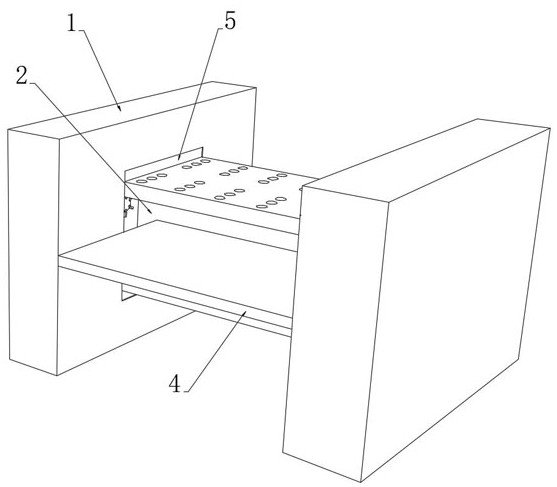

[0043] see Figure 1-3 , a composite thermal insulation steel-reinforced concrete integrated building structure, including a pair of wall panels 1 and an I-shaped steel 2 fixedly embedded between the pair of wall panels 1, and the opposite side walls of the pair of wall panels 1 are dug with embedding cavities, The two ends of the I-shaped steel 2 respectively extend into two embedded cavities, and the two embedded cavities are equipped with U-shaped steel 5 connected with the two ends of the I-shaped steel 2. The I-shaped steel 2 on the one hand serves as two wall panels 1 On the other hand, the steel structure is used to connect to enhance the connection strength between the wall panels.

[0044] see Figure 3-5 The upper and lower end surfaces of the I-shaped steel 2 are provided with a plurality of seepage holes 201, and the left and right sides of the upper and lower end surfaces of the I-shaped steel 2 are embedded with a plurality of hot-melt adhesive pockets correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com