A tile sewing machine

A technology for beautiful seams and ceramic tiles, applied in the field of ceramic tile beauty sewing machines, can solve the problems of uneven filling, time-consuming and laborious, low efficiency, etc., and achieve the effect of saving manpower, compact structure of the whole machine, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

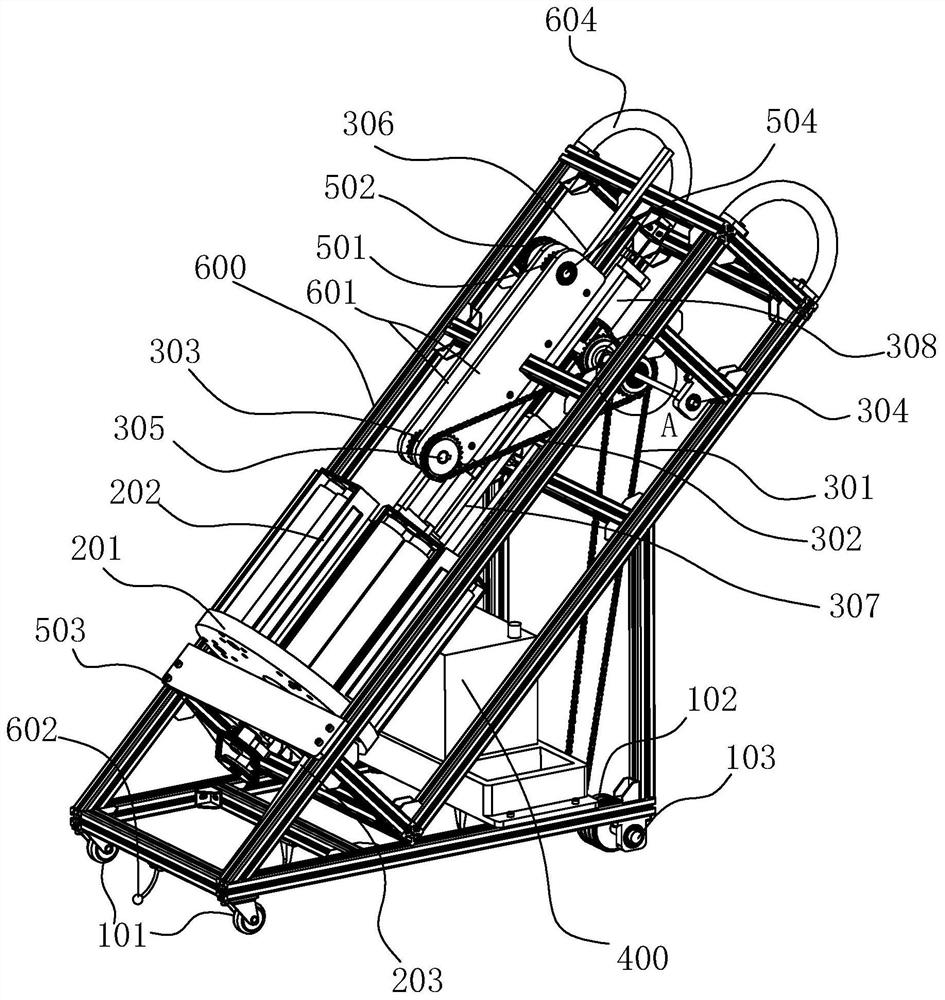

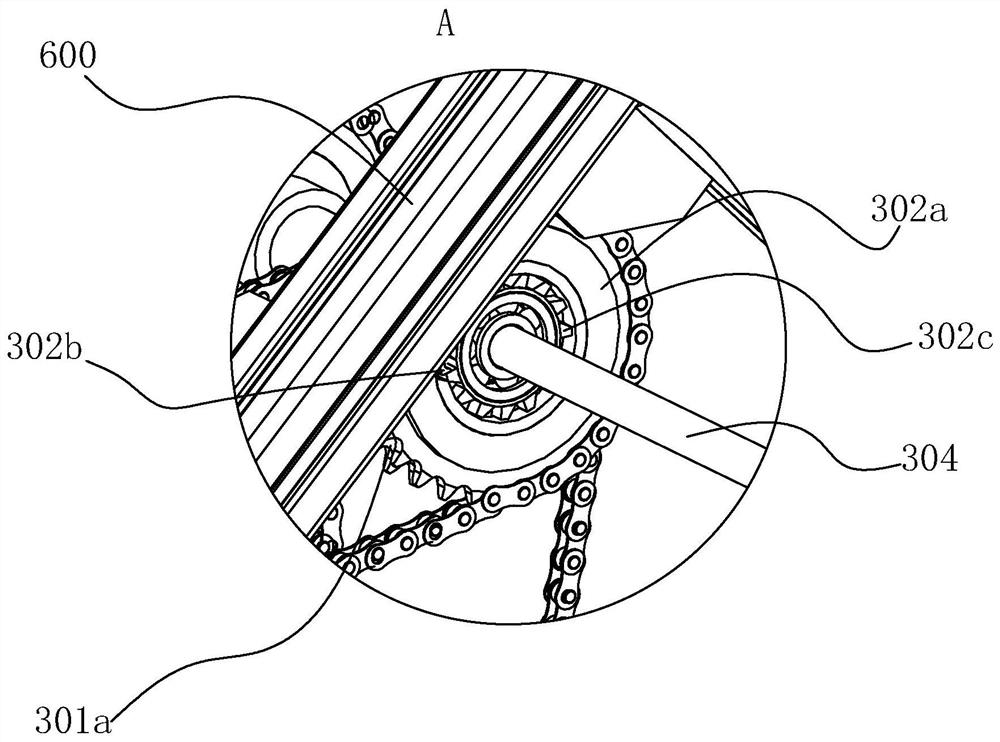

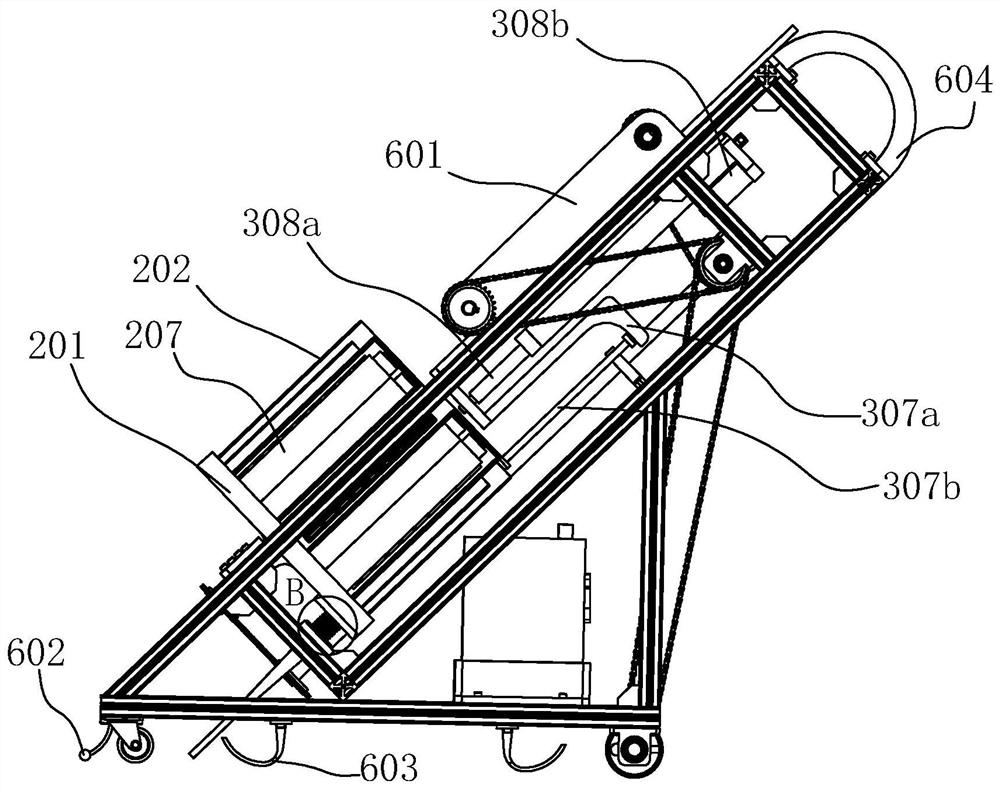

[0035] In order to clearly illustrate the technical characteristics of this program, the following specific implementation methods, combined with its attached Figures 1 to 13 , the present invention is described in detail.

[0036] Reference attached Figures 1 to 13 : The beautiful sewing machine for ceramic tiles in the present embodiment includes frame 600, and the frame 600 is mainly equipped with traveling mechanism, rubber material holder, feeding device, refueling device and control device 400, and these mechanisms and devices are installed on the frame The layout on is adapted to the connection relationship between them, such as figure 1 As shown, the ceramic tile beautifying machine of this embodiment has a reasonable structure, a compact layout, and various mechanisms and devices work in a coordinated and orderly manner. The rack 600 here is composed of aluminum profiles, which is light and strong.

[0037] Running mechanism comprises the front wheel group 101 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com