Sleeve outer wall polishing device

A casing and outer cylinder technology, which is applied in the field of casing outer wall grinding devices, can solve problems such as poor casing sealing, and achieve the effects of increasing safety and reducing the risk of being cut off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be further described below in conjunction with specific examples.

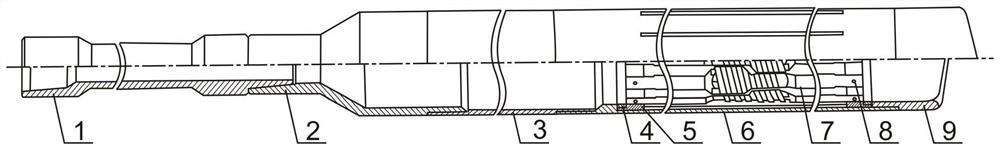

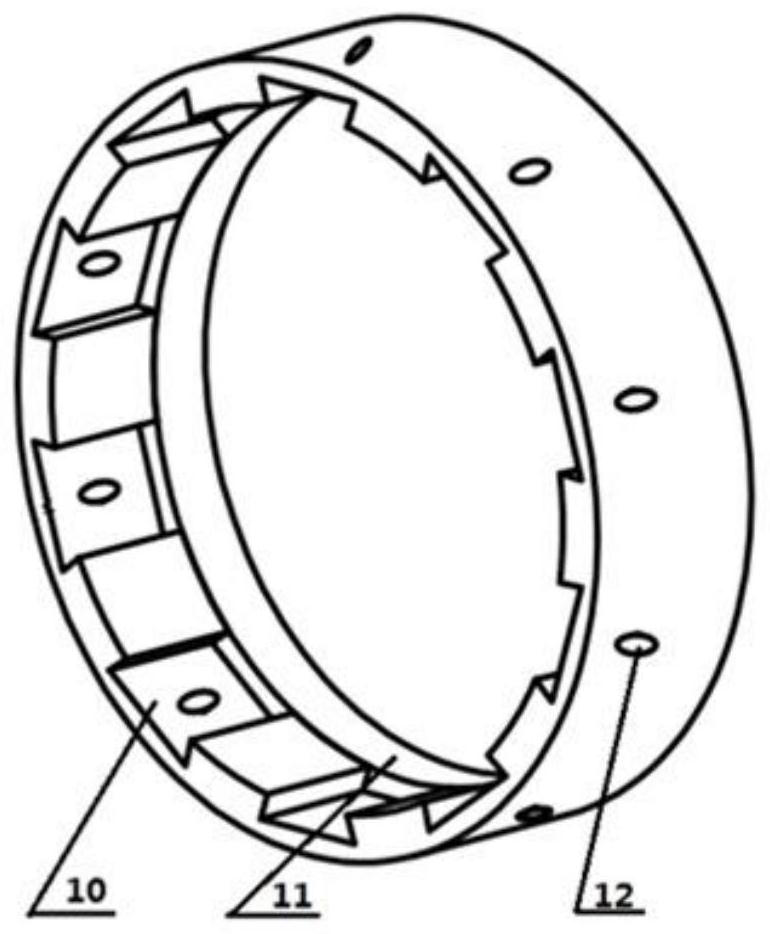

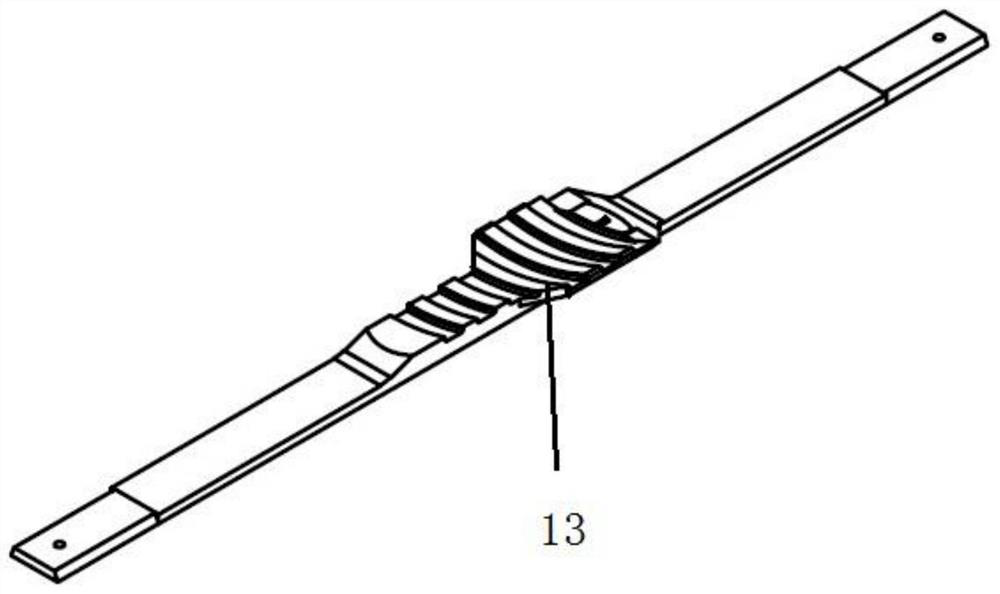

[0021] Such as figure 1 As shown, this embodiment provides a casing outer wall grinding device, which is in the shape of a cylinder as a whole, and at least includes an upper joint 1, a change button 2, an extension tube 3, a grinding section, and a guide shoe 9 from top to bottom, and sequentially Threaded connection is adopted; the upper end of the upper joint 1 is a female buckle; the lower part of the guide shoe 9 is in a spiral shape, which is convenient for being inserted into the pipe string during the rotation.

[0022] The variable buckle 2 is divided into upper, middle and lower sections as a whole, the upper section is smaller in size, the lower section is larger in size, and the middle section is used as a transition section between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com