Shield segment

A technology of shield segment and segment, which is applied in wellbore lining, tunnel lining, underground chamber, etc., can solve the problems of affecting the safety of use, poor connection stability, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

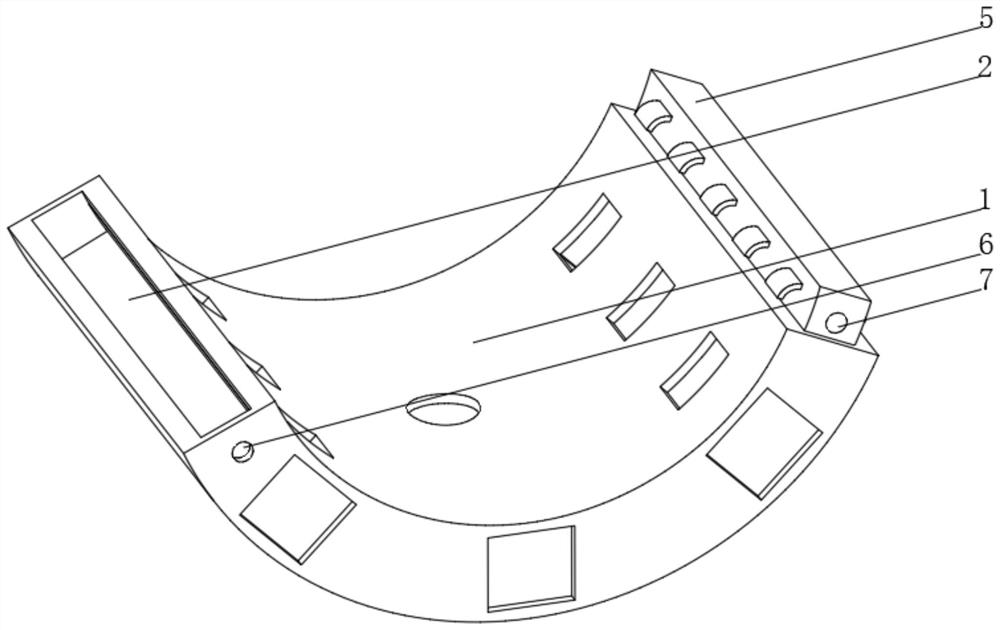

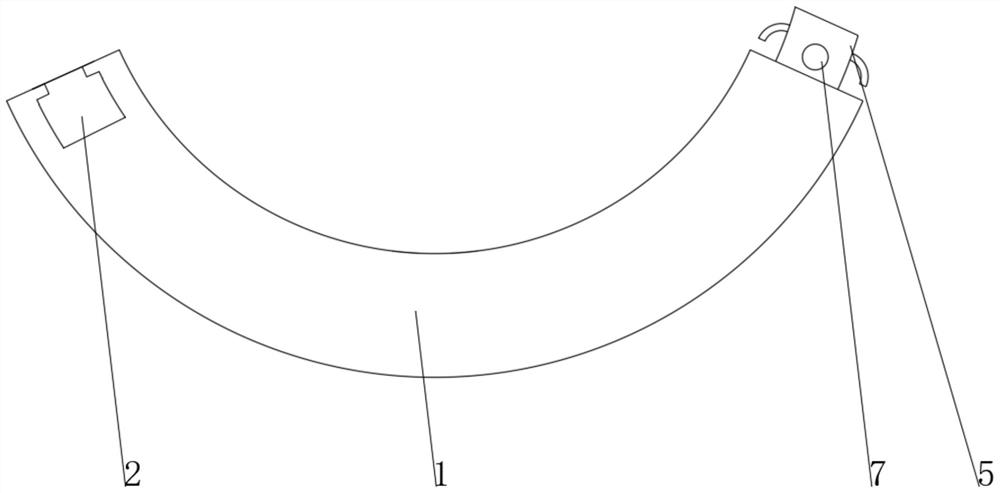

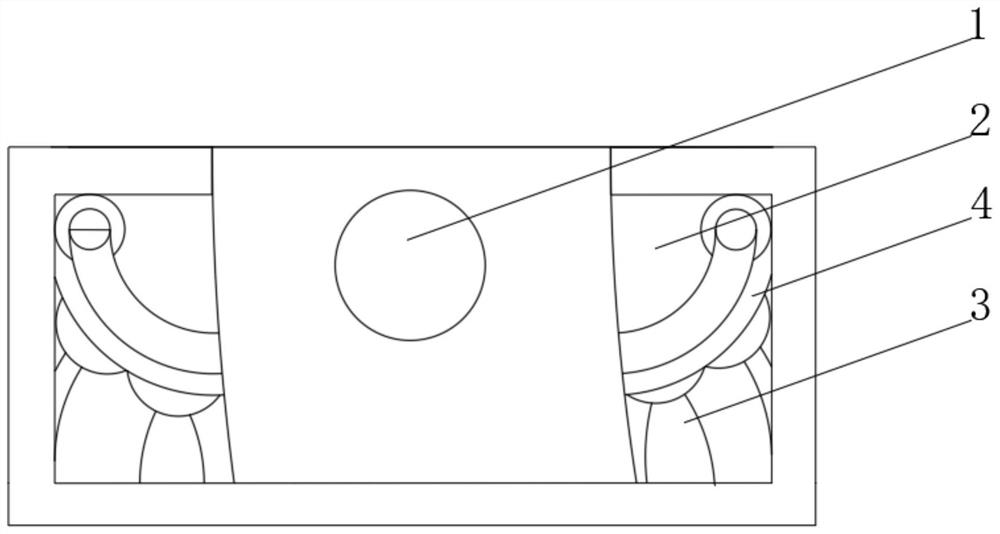

[0031] see Figure 1-4 , the present invention provides a technical solution: a shield segment, including a segment body 1, one end of the segment body 1 is provided with a mounting groove 2, the bottom of the inner wall of the mounting groove 2 is fixedly connected with a support rod 3, and the inner wall of the mounting groove 2 is a There is an air hole 6 on the side, the top of the support rod 3 is fixedly connected with an arc-shaped support plate 4, and the end of the segment body 1 away from the installation groove 2 is fixedly connected with a chuck 5, and the side of the chuck 5 is provided with an air nozzle 7, and the chuck 5 Including the chuck body 51, both sides of the chuck body 51 are provided with a chuck groove 52, the bottom of the inner wall of the chuck groove 52 is fixedly connected with a fixing seat 53, and both sides of the top of the fixing seat 53 are rotatably connected with an arc spring 54. The top of the spring 54 is rotatably connected with a ro...

Embodiment 2

[0034] see Figure 1-5On the basis of Embodiment 1, the present invention provides a technical solution: the rotating clamp 55 includes a clamp body 551, one end of the clamp body 551 is provided with an arc-shaped groove 552, and the bottom of both sides of the inner wall of the arc-shaped groove 552 is fixedly connected with Spring piece 553, the end of spring piece 553 away from arc groove 552 is connected with arc rod 554 in rotation, the end of arc rod 554 away from spring piece 553 is connected with roller 555 through rotation bolt rotation, and the bottom of clamp body 551 is fixedly connected with reinforcement Block 556, the reinforcing block 556 is fixedly connected with an arc-shaped reinforcing bar 557 on one side away from the clamp body 551, and is provided with an arc-shaped rod 554 and a spring leaf 553. The inside of 551 shrinks, which can avoid the failure of installation caused by the dimensional error between the installation groove 2 and the rotating clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com