A spherical three-dimensional force measuring piezomagnetic sensor and three-dimensional force measuring method

A piezomagnetic sensor and three-dimensional force measurement technology, applied in the field of force measurement, can solve the problems of inability to obtain accurate values of induced voltages, coupling errors in multiple dimensions, and measurement of excitation voltages that are suddenly large and small, so as to improve measurement accuracy and The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

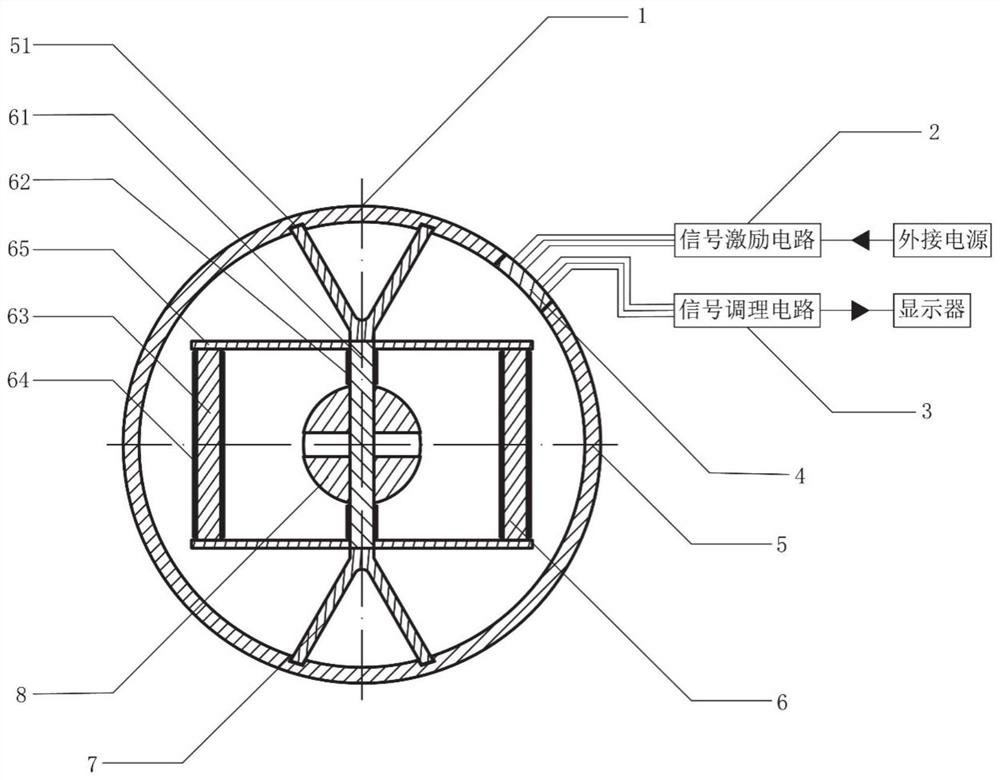

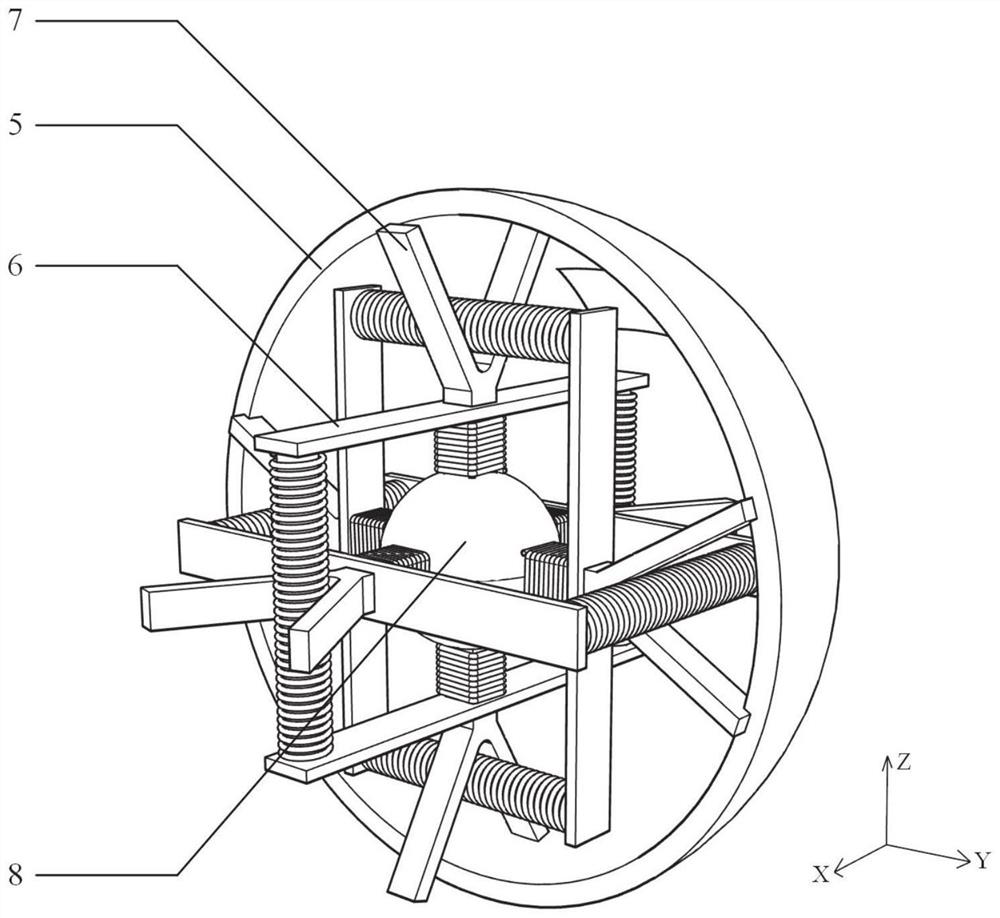

[0039] Such as figure 1 As shown, the present embodiment provides a spherical three-dimensional force-measuring piezomagnetic sensor, comprising: a force-measuring mechanism 1, a signal excitation circuit 2 and a signal conditioning circuit 3; The force transmission element 7 connected in the three-dimensional orthogonal direction of the inner surface and the piezoelectric element 6 connected with the force transmission element 7;

[0040] The piezoelectric element 6 receives the external force exerted on the spherical shell 5 through the force transmission element 7;

[0041] After the piezomagnetic element 6 receives an external force, the signal excitation circuit 2 transmits an excitation signal to the piezomagnetic element 6, so that the piezomagnetic element 6 converts the external force into a non-zero induced voltage, and transmits the induced voltage to the signal conditioning circuit 3 ;

[0042] The signal conditioning circuit 3 performs signal compensation, outpu...

Embodiment 2

[0069] Based on the specific structure of the spherical three-dimensional force-measuring piezomagnetic sensor described in Embodiment 1, this embodiment provides a three-dimensional force measurement method for a spherical three-dimensional force-measuring piezomagnetic sensor, including:

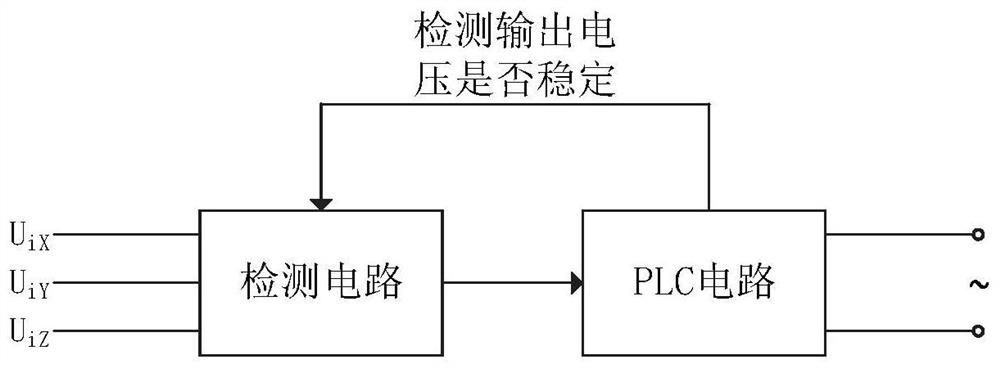

[0070] After applying an external force to the force measuring mechanism, the external force is decomposed into component forces in multiple directions orthogonally, and the force measuring mechanism receives the component force and the excitation signal transmitted by the signal excitation circuit, so that the external force is converted into a non-zero induced voltage, and transmit the induced voltage to the signal conditioning circuit;

[0071] After the signal conditioning circuit performs signal compensation, output decoupling and component force synthesis on the induced voltage, the external force value and the component force value in each direction are obtained.

[0072] The embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com