Wafer surface metal film thickness measuring method

A surface metal and measurement method technology, applied in semiconductor/solid-state device testing/measurement, electrical components, electrical solid-state devices, etc., can solve the problems of increased plating time, reduced production capacity, increased cost, etc., to achieve high measurement accuracy, The effect of avoiding damage and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

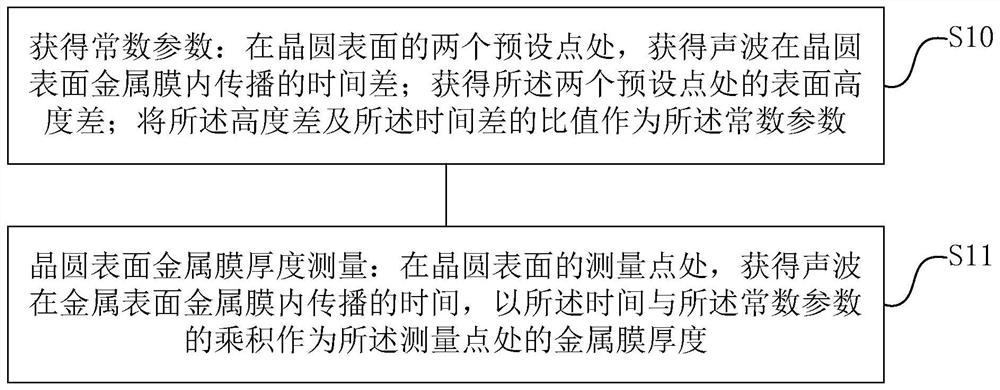

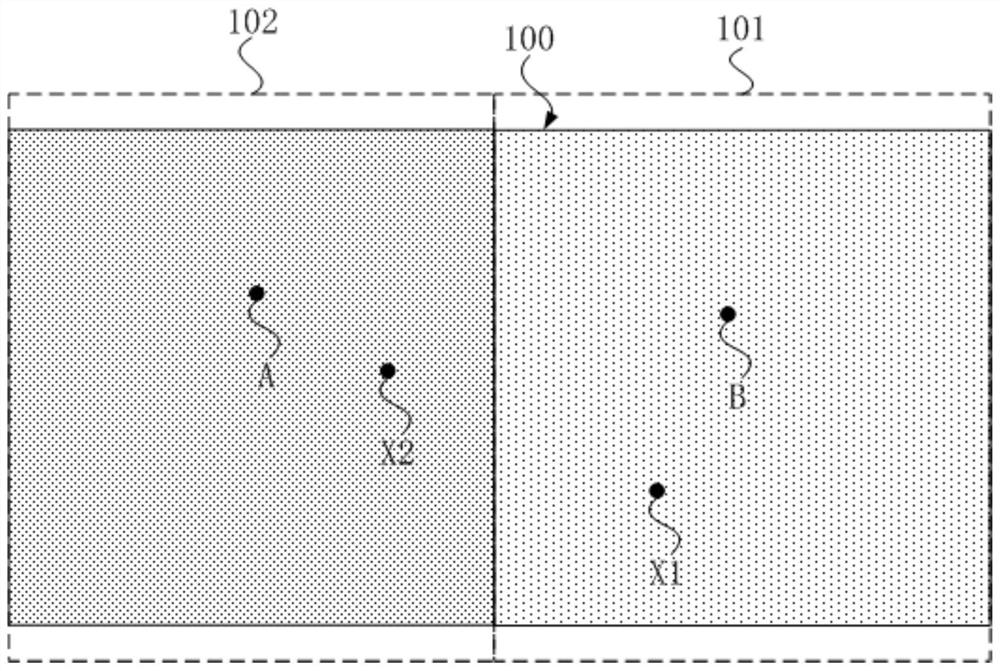

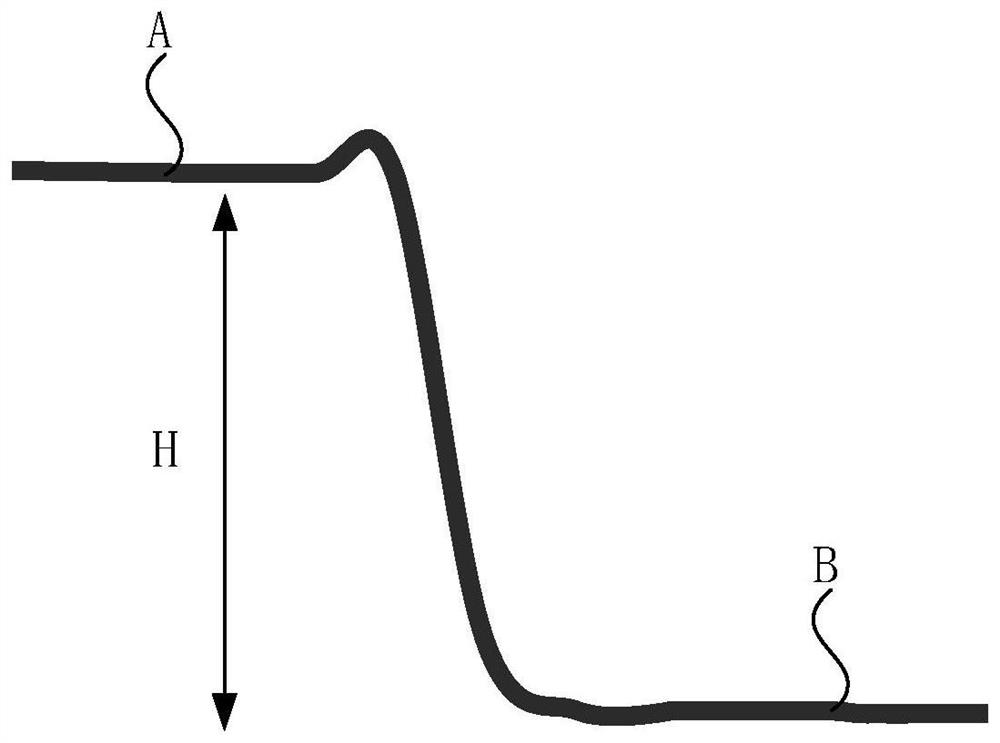

[0027] The specific implementation of the method for measuring the thickness of the metal film on the wafer surface provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] As mentioned in the background art, there is no real-time means for monitoring the thickness of the metal film at the metal coating process site. It is usually necessary to measure the thickness of the metal layer after the metal grinding process, which fails to achieve the purpose of real-time monitoring, and in order to make the thickness of the metal interconnection line in the loose area and the dense area after the metal grinding process meet the requirements, when electroplating metal It will increase the plating thickness, resulting in reduced production capacity and increased costs.

[0029] Therefore, the present invention provides a method for measuring the thickness of the metal film on the surface of the wafer, which can monitor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com