Aluminum alloy plate

A technology of aluminum alloy plate and quality, applied in the field of aluminum alloy plate, can solve the problems of increased wall thickness, large compressive stress of tank wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

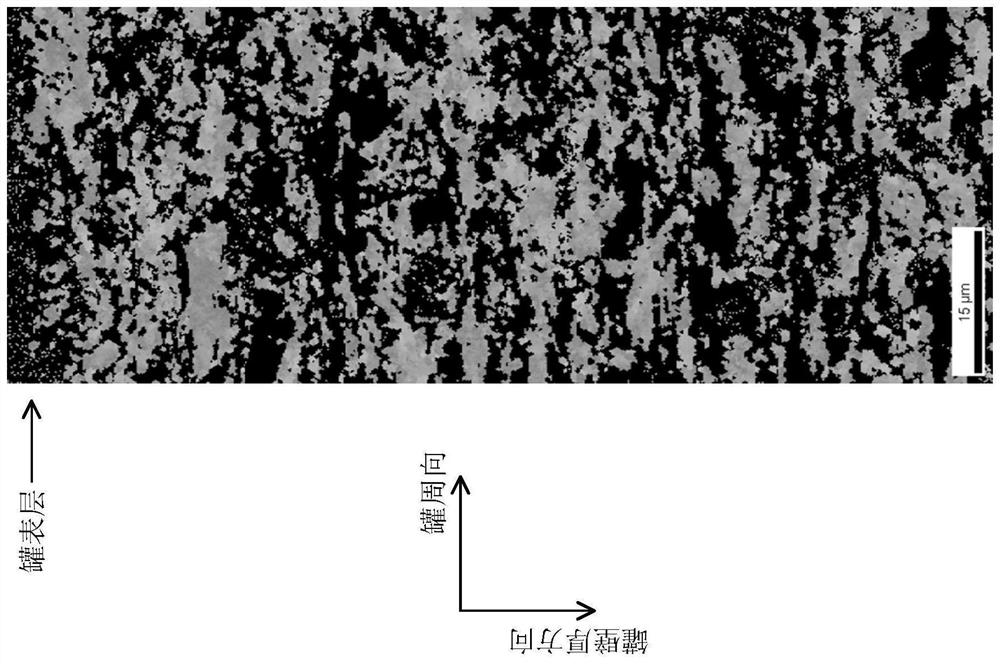

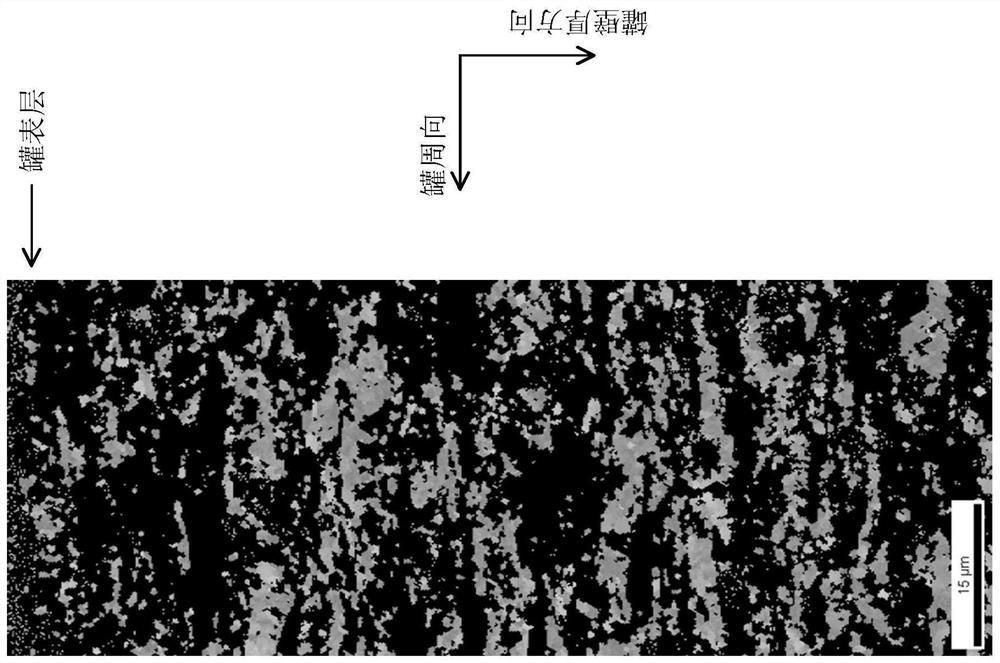

Image

Examples

Embodiment Construction

[0018] Exemplary embodiments of the present disclosure will be described with reference to the drawings.

[0019] 1. Components of aluminum alloy plate

[0020] The aluminum alloy plate of the present disclosure contains 0.4 mass % or more and 1.5 mass % or less of Mn. The solid solution or precipitation of Mn in the aluminum alloy sheet of the present disclosure contributes to the improvement of the strength of the aluminum alloy sheet. Therefore, Mn increases the tensile strength of the aluminum alloy sheet of the present disclosure. By setting the content of Mn to be 0.4% by mass or more, the aluminum alloy sheet of the present disclosure has high tensile strength. The content of Mn is preferably 0.7% by mass or more. When the content of Mn is 0.7% by mass or more, the formability of the aluminum alloy sheet of the present disclosure is more excellent.

[0021] Conventionally, a giant compound (Giant Compound) may be generated in an aluminum alloy plate. Giant compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com