Dental whitening and degerming coating material and preparation method and application thereof

A coating material and whitening technology, used in tooth protection coatings, dental preparations, dentistry, etc., can solve problems such as tooth surface damage, stimulation of oral mucosa, and limited whitening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the dental whitening and antibacterial coating material comprises the following steps:

[0030] (1) Mix the powder materials in proportion, SiO 2 , The mass sum of piezoelectric materials and additives is 100%.

[0031] (2) Mill the material obtained in step (1) at high speed in a ball mill to obtain a mixture. The milling speed is 800-2000r / min, preferably 1000-1500r / min, and the milling time is 2-16h, preferably 10-16h.

[0032] (3) mixing the mixture obtained in step (2) with the blending liquid to obtain a paste material; the blending liquid is used as a mixture dispersion to improve adhesion, and is composed of glycerin, water and povidone K30, and the mass ratio It is (2-4): (3-5): (1-4), preferably 4:5:1; the mass ratio of the mixture to the blended liquid is (2-3): (1-2), preferably 2: 1;

[0033] (4) Apply the paste material obtained in step (3) to the outside of the dental restoration matrix, completely wrap the dental restoration ...

Embodiment 1

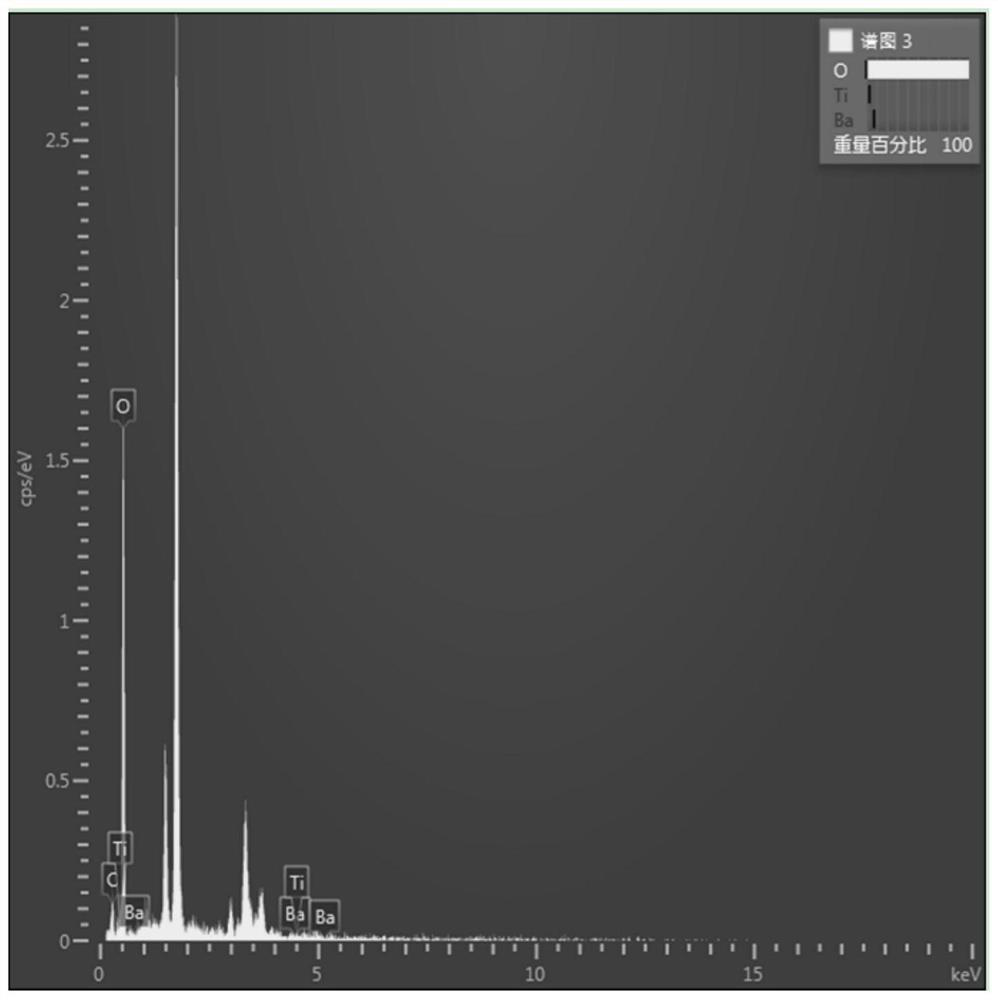

[0036] (1) According to the content of the ingredients shown in Table 1, take the required raw material ingredients and mix them thoroughly and evenly.

[0037] Table 1 example 1 material content formula

[0038] components Mass content wt% SiO 2

70 al 2 o 3

3 K 2 o

4 CeO 3 ZrO 5 P 2 o 5

5 BaTiO 3

10

[0039] (2) Ball mill the mixed material for 16 hours at a rotating speed of 800r / min to obtain a well-mixed and well-dispersed mixture.

[0040] (3) Blend the obtained mixed powder with the blending solution at a mass ratio of 2:1 to prepare a paste material. The blending solution is composed of glycerol, water and povidone K30 in a mass ratio of 4:5:1.

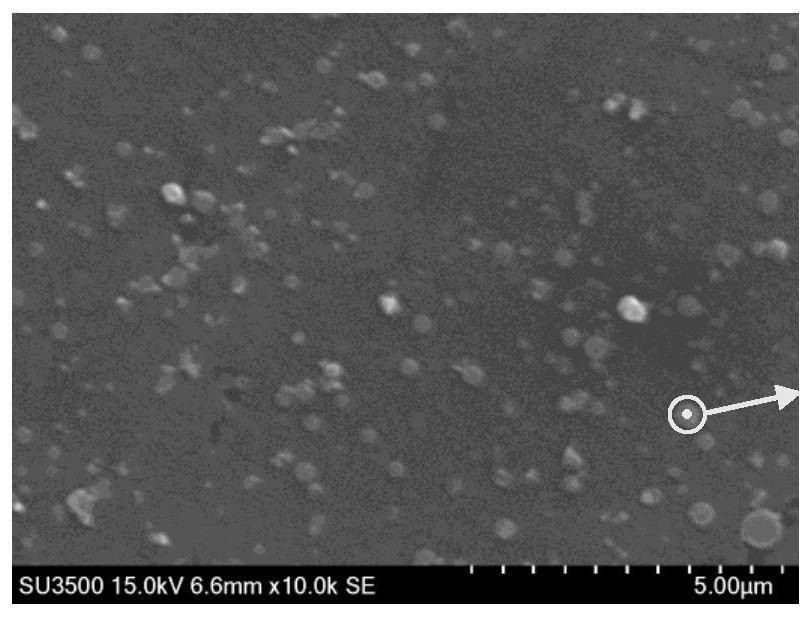

[0041] The resulting paste was coated on the surface-treated base of the metal-ceramic dental restoration, and was cured at 770°C for 20 minutes.

[0042] A dental restoration with whitening and antibacterial functions is obtained.

[0043] f...

Embodiment 2

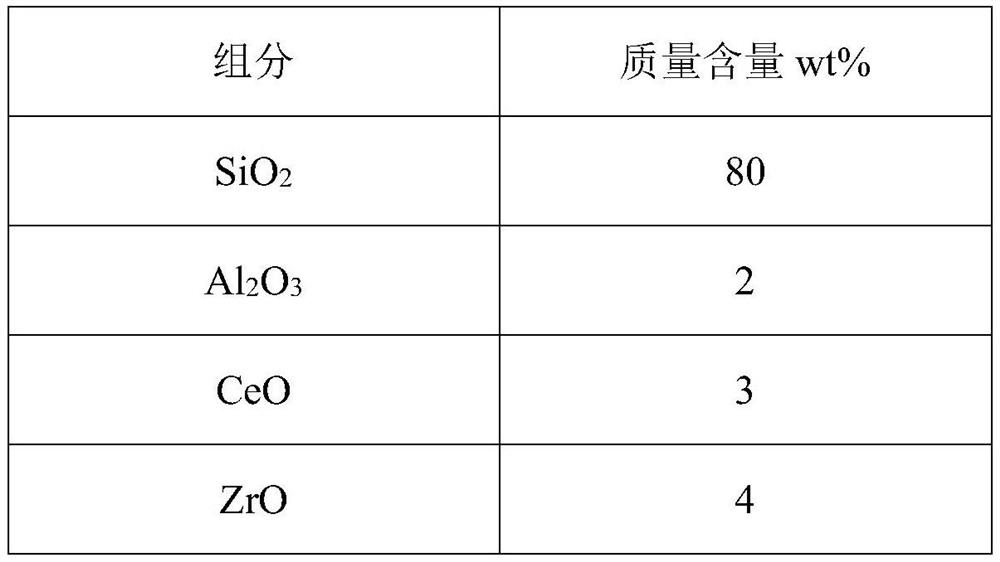

[0045] (1) According to the content of the ingredients shown in Table 2, take the required raw material ingredients and mix them thoroughly and evenly.

[0046] Table 2 example 2 material content formula

[0047]

[0048]

[0049] (2) Ball mill the mixed material for 12 hours at a rotational speed of 1000 r / min to obtain a mixed powder material with uniform mixing and good dispersibility.

[0050] (4) Blend the obtained mixed powder with the blending solution at a mass ratio of 3:1 to prepare a paste material. The blending solution is composed of glycerol, water and povidone K30 in a mass ratio of 4:5:1.

[0051] (3) Apply the obtained paste on the base of the all-ceramic dental restoration after surface treatment, and heat it at 800° C. for 15 minutes to solidify to obtain a dental restoration with whitening and sterilization functions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com