Automatic gluing machine for bipolar plate of fuel cell

A fuel cell, bipolar plate technology, applied in battery electrodes, circuits, coatings, etc., can solve problems such as glue coating position deviation, track range overlap, safety hazards, etc., to reduce costs, avoid safety hazards, and avoid coating. The effect of glue position deviation and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

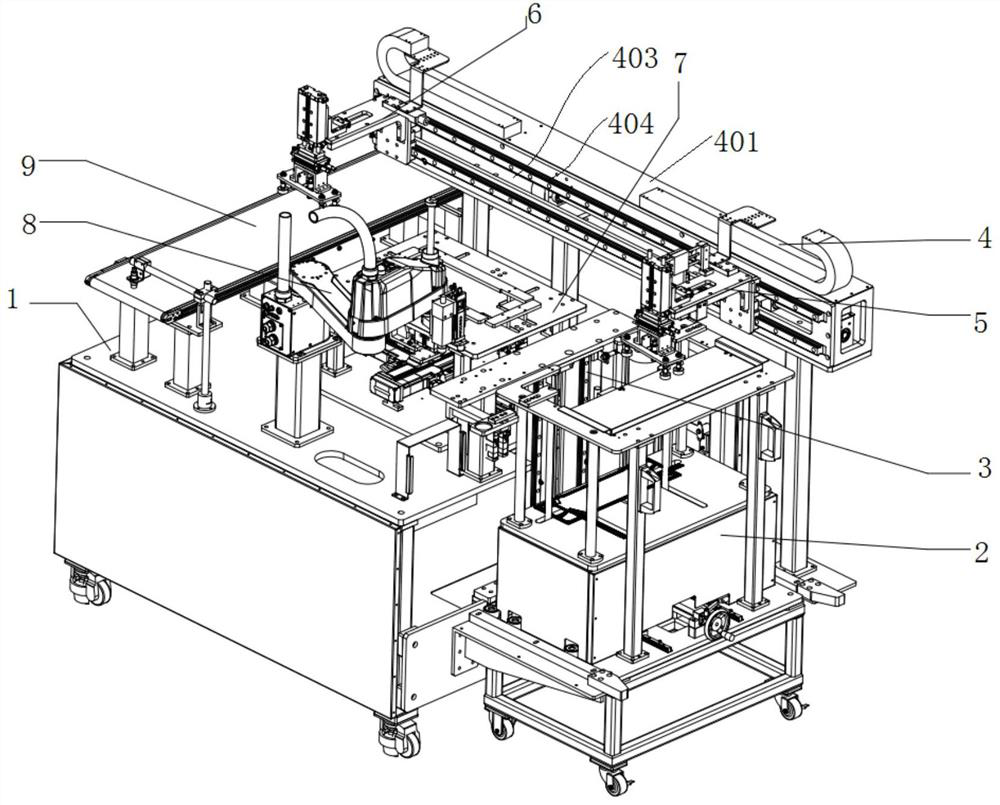

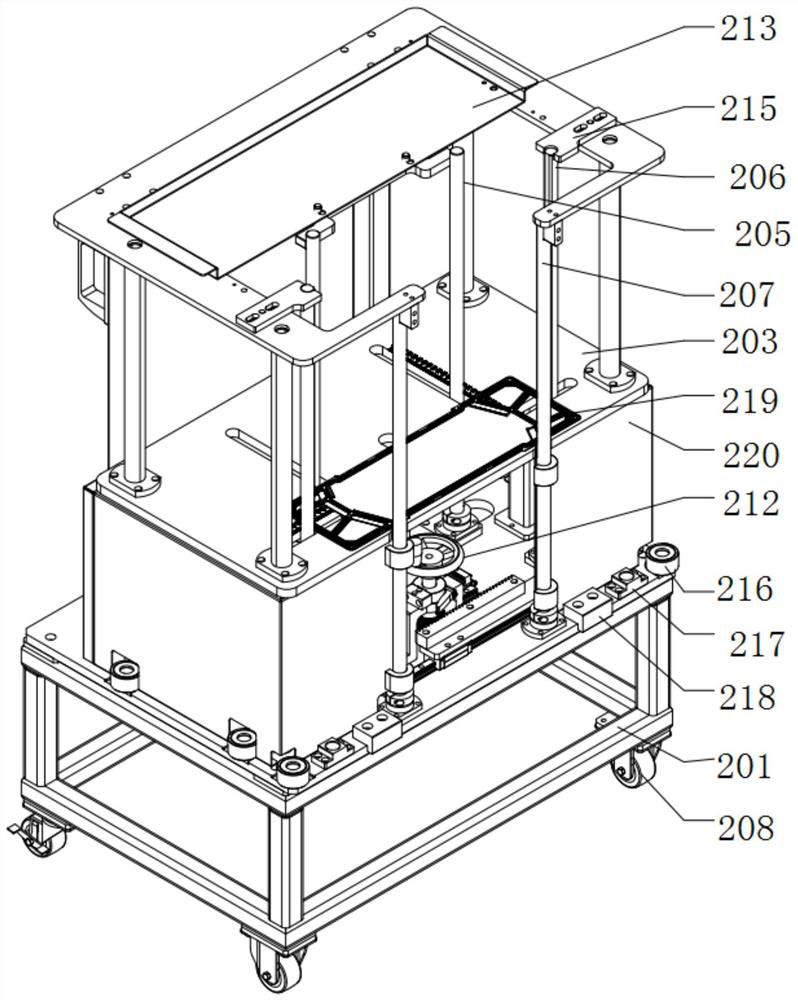

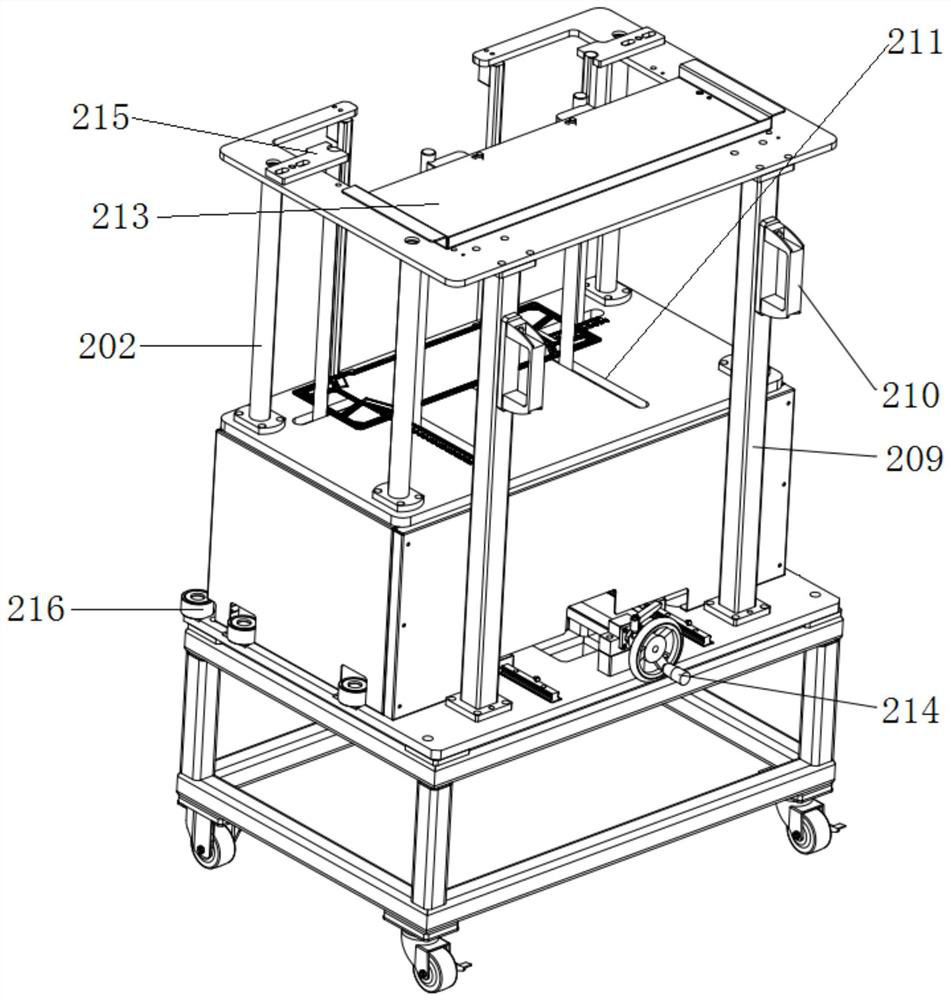

[0069] The fuel cell bipolar plate automatic gluing machine of the present application includes a base 1, a plate trolley loading module 2, a silo jacking module 3, a plate loading and unloading conveying module 4, a plate material grabbing module 5, and a plate The blanking and grabbing module 6, the plate positioning and edge-holding module 7, the robot gluing module 8, and the conveyor belt delivery module 9 and other modules.

[0070] See figure 1 As shown, the base 1 is used as a support for supporting the installation of various components. The pole plate trolley feeding module 2 is movably connected to one side of the base 1, and the pole plate trolley loading module 2 is used to centrally provide unglued pole plates. The silo jacking module 3 is fixed on the base 1 on the side close to the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com