Automatic product sorting equipment

An automatic sorting and product technology, applied in sorting, vibrating conveyors, conveyor control devices, etc., can solve the problems of reduced work efficiency, missed sorting and missed inspection, and high sorting costs, and achieve convenient maintenance and maintenance. Maintenance costs, the effect of avoiding manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

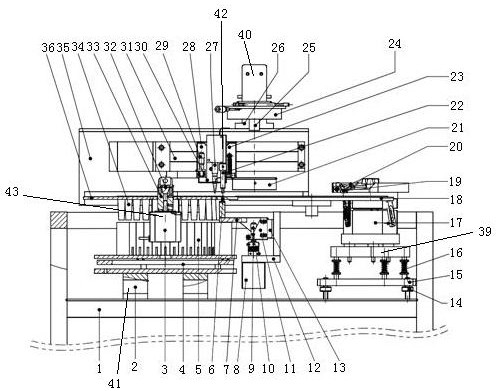

[0021] Below in conjunction with accompanying drawing, the present invention will be further described.

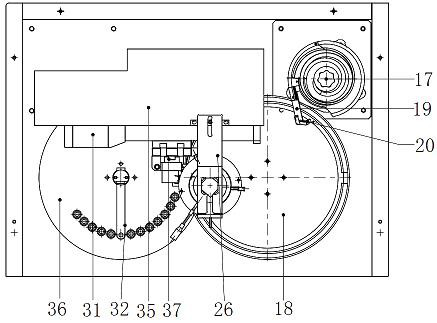

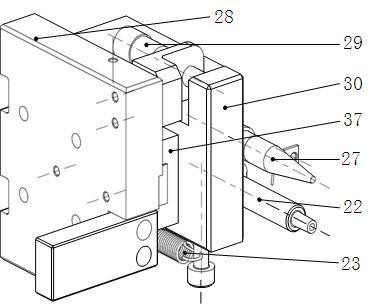

[0022] like figure 1 As shown, the circular vibration feeder 17 is fixed on the shock absorber 15 by the spring shock absorber 16, and the shock absorber 15 is fixed on the frame 1 by the damper 14. Pour the product to be tested into the tray of the circular vibration feeder 17, and start the circular vibration feeder 17 to move the product along the material path of the tray, and move in a single row orderly under the action of the sliding sheets of the tray. When moving to the extended forehearth 19, utilize as Figure 4 The shown extended material channel 19 is a downwardly curved material channel, under the joint action of the acceleration of gravity and the circular shock, a small distance is drawn between the products, so as to detect each monomer. When the product moves to the end of the extended material channel 19, it is judged by the optical fiber sensor 20, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com