Automatic pipe bending equipment

A technology of automation equipment and pipe bending, which is applied in the direction of metal processing equipment, storage devices, feeding devices, etc., can solve the problems of increasing the manufacturing cost of tooling molds, large deformation of tooling mechanisms, and inability to reuse, so as to improve efficiency and operation Convenience, reasonable and scientific effect of unit structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

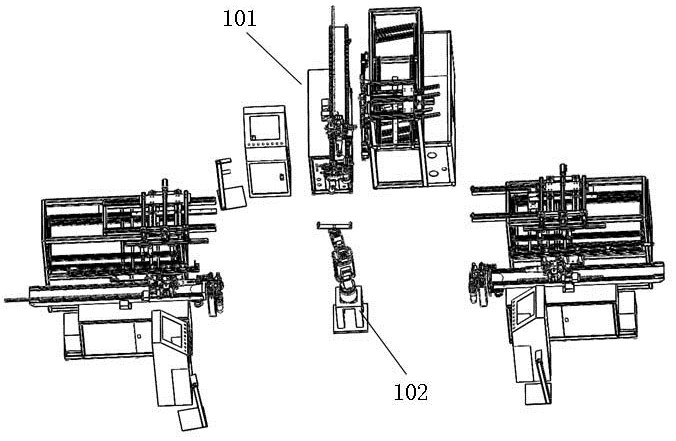

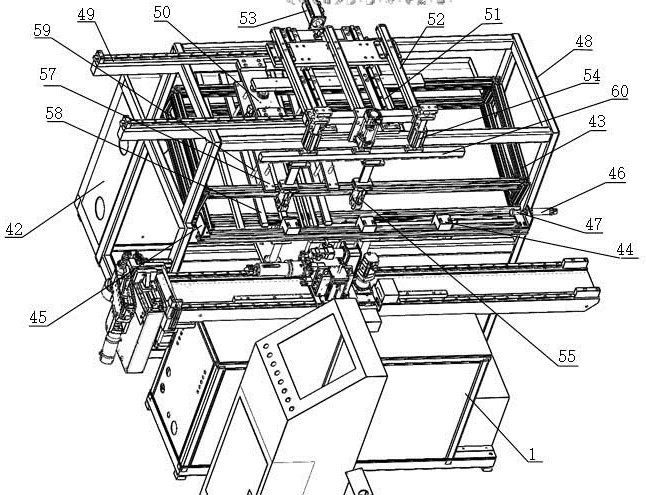

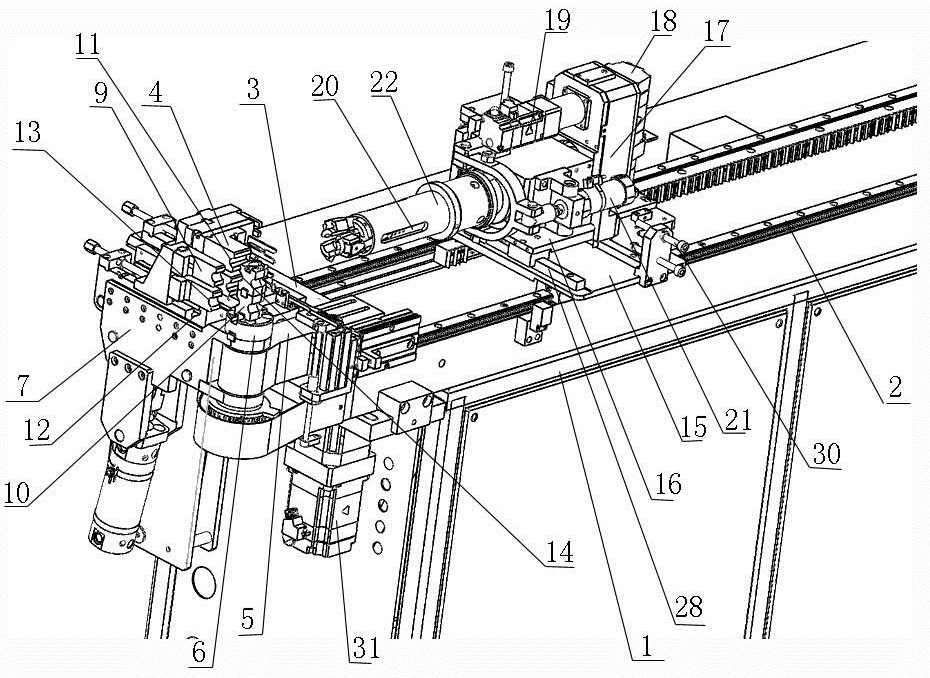

[0046] Such as Figure 1-6 As shown, the pipe bending automation equipment includes a workbench b1 and a bending mechanism;

[0047] It includes three sets of automatic bending devices 101 arranged in a "pin" shape, and a blanking manipulator 102 located in the middle of the three sets of automatic bending devices;

[0048] The automatic bending device 101 includes a workbench b1 and a workbench a42; a bending mechanism is provided on the workbench b1; the bending mechanism is arranged on the workbench b1; the bending mechanism includes Sample delivery track 2, clamping moving mechanism, rotating driving mechanism 31, mounting seat a3, ejector positioning block 4, mounting seat b5, rotating shaft a6, rotating seat 7, chute b12, driving mechanism, ejecting block a9, ejector Material block b10; the top surface of the workbench b1 is provided with a horizontal sample delivery track 2 along its left and right directions;

[0049] The mounting seat a3 and the mounting seat b5 are...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap