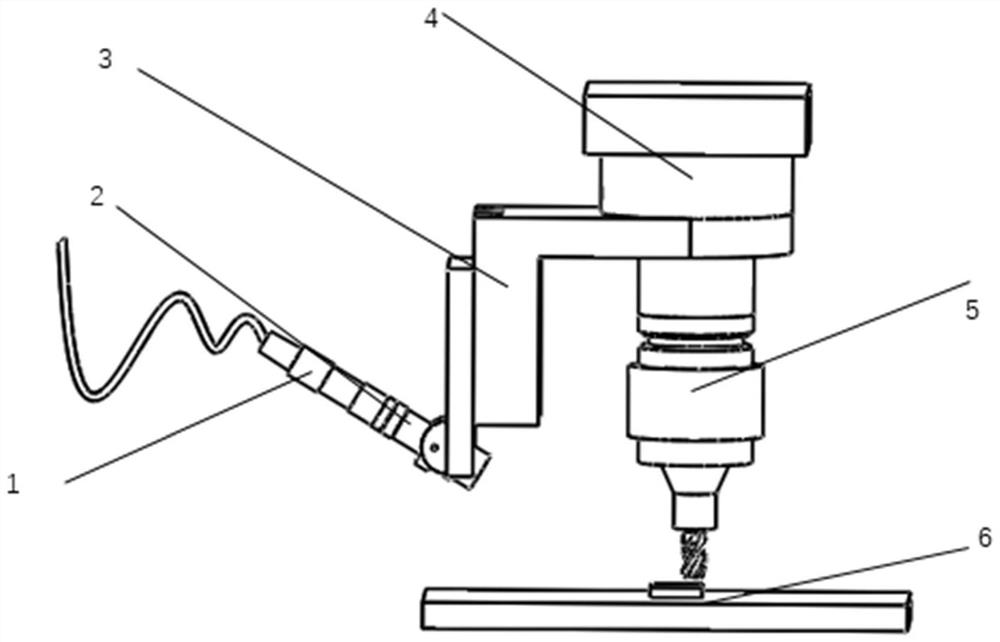

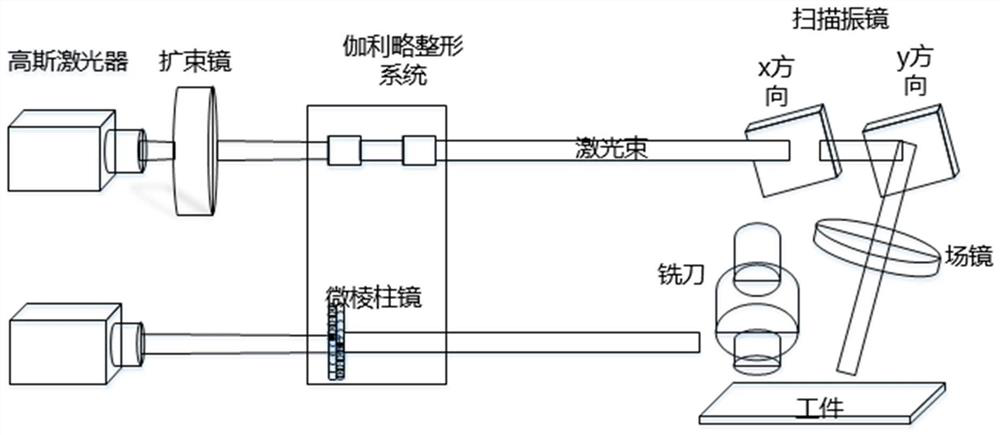

Shimming laser-assisted milling machining device and method suitable for difficult-to-machine materials

A milling and laser-assisted technology, used in metal processing, laser welding equipment, metal processing equipment, etc., can solve the problems of affecting the processing quality of workpieces, low degree of material softening, uneven thermal softening, etc., to solve the problem of high-efficiency precision machining , The effect of improving machinability and improving machinability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

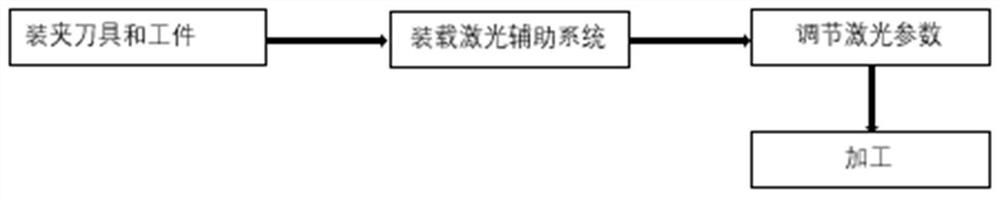

Method used

Image

Examples

Embodiment Construction

[0021]Next, the technical solutions in the embodiments of the present invention will be described in contemplation in the embodiment of the present invention, and it is apparent that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention in all other embodiments obtained without making creative labor.

[0022]In the description of the present invention, it is to be noted that the orientation or positional relationship indicated by the term "upper", "region" is based on the orientation or positional relationship shown in the drawings, and is merely described in order to facilitate the description of the present invention and simplified description. Instead of indicating or implying that the device or component must have a particular orientation, constructing and operating in a particular orientation, and thus is no...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap