A kind of copolymerized aromatic-aliphatic semi-aromatic nylon and its preparation method

A semi-aromatic nylon and aliphatic technology, which is applied in the preparation field of copolymerized aromatic-aliphatic semi-aromatic nylon, can solve the problems of insufficient understanding of semi-aromatic nylon, and achieve good market application prospects, excellent toughness and weather resistance, and good application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

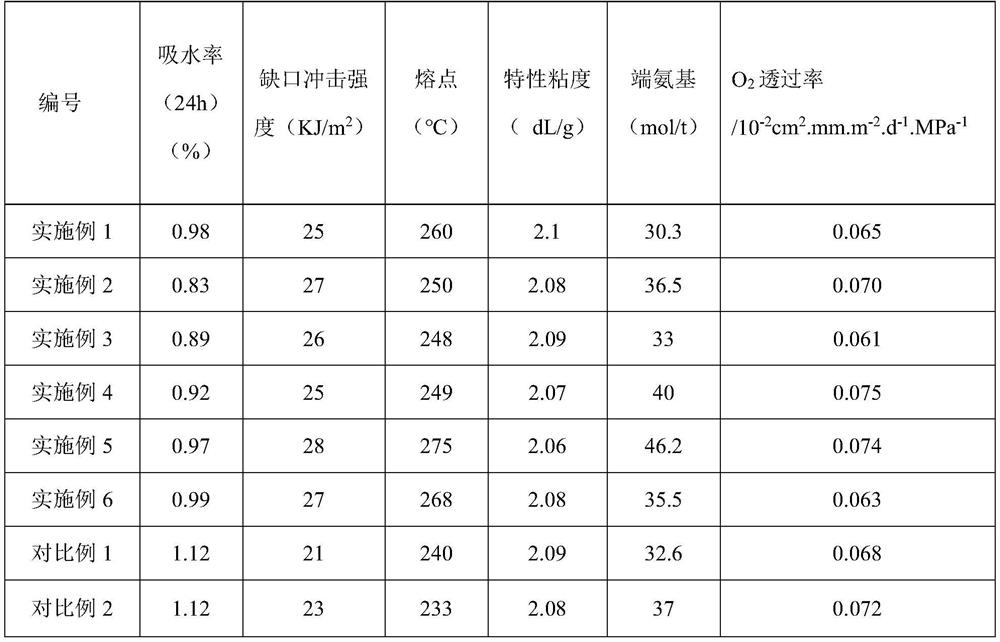

Examples

Embodiment 1

[0054] Step 1: Accurately weigh 100 g of xylylenediamine raw material and aliphatic diacid raw material with a molar ratio of 1:1. Wherein, the xylylenediamine raw material comprises p-xylylenediamine and m-xylylenediamine, and the mol ratio of p-xylylenediamine and m-xylylenediamine is 50:50, and the raw material of aliphatic diacid is adipic acid. Under an inert atmosphere, add the above-mentioned raw materials into an autoclave equipped with 300ml of distilled water, react for 4 hours under the condition of stirring at a water temperature of 80°C, and then add p-xylylenediamine to adjust the pH of the aqueous solution to 7.0 according to the neutralization reaction , after the pH value was stabilized, the stirring reaction was continued at constant temperature for 1.5 hours to obtain a nylon salt aqueous solution system.

[0055] Step 2, transfer the nylon salt aqueous solution obtained in step 1 to a 500ml polymerization reactor, add 0.1g of phosphorous acid, replace the a...

Embodiment 2

[0058] Step 1: Accurately weigh 100 g of xylylenediamine raw material and aliphatic diacid raw material with a molar ratio of 1:1. Wherein, the xylylenediamine raw material includes p-xylylenediamine and m-xylylenediamine, the molar ratio of p-xylylenediamine and m-xylylenediamine is 50:50, and the aliphatic diacid is dodecanoic acid, adding In 400ml of distilled water, react for 4 hours at a water temperature of 80°C with stirring, then add m-xylylenediamine to adjust the pH of the aqueous solution to 7.0 according to the neutralization reaction, and continue the reaction at a constant temperature for 2 hours after the pH value is stable. A nylon salt aqueous solution system is obtained.

[0059] Step 2: Transfer the nylon salt aqueous solution obtained in step 1 to a 1L polymerization reactor, add 0.1 g of phosphorous acid, replace the air in the polymerization reactor with nitrogen, and keep nitrogen at a pressure of 0.2 MPa as a protective gas. Slowly heat the reactor, us...

Embodiment 3

[0062] Step 1: Accurately weigh 100 g of xylylenediamine raw material and aliphatic diacid raw material with a molar ratio of 1:1. Among them, xylylenediamine raw materials include p-xylylenediamine and m-xylylenediamine, the molar ratio of p-xylylenediamine and m-xylylenediamine is 50:50, the aliphatic diacid is sebacic acid, add 400ml In distilled water, react for 4 hours at a water temperature of 80°C with stirring, then add m-xylylenediamine to adjust the pH of the aqueous solution to 7.2 according to the neutralization reaction, and continue the reaction at a constant temperature for 2 hours after the pH value stabilizes to obtain Nylon saline solution system.

[0063] Step 2, transfer the nylon salt aqueous solution obtained in step 1 to a 500mL polymerization reactor, and add 0.1g of phosphoric acid, replace the air in the polymerization reactor with nitrogen, and keep nitrogen at a pressure of 0.2MPa as a protective gas. Slowly heat the polymerization reactor, use 2.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com