Mortar scraping device

A technology of main body and inclined plane, applied in the direction of building and building structure, can solve the problems such as the inability to discharge air bubbles in the mortar layer, and achieve the effect of ensuring construction quality and preventing hollowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0021] As recorded in the background technology, in the process of installing tiles, people need to stick the tiles on the wall or the ground with tile glue, mortar, etc. In the related art, the constructor usually uses a shovel to apply the mortar, and then The scraper is used to scrape the mortar to make the surface of the mortar smooth. However, after the scraping process, due to the uneven coating, there will be air bubbles in the mortar layer, and the air bubbles cannot be discharged in time. After the surface is tiled, the tiles will bulge, which will affect the construction quality.

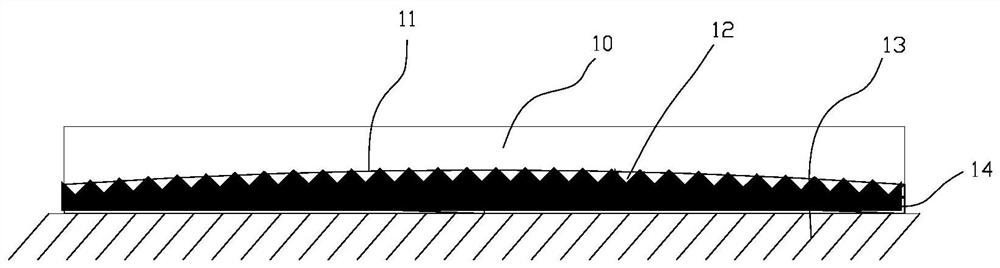

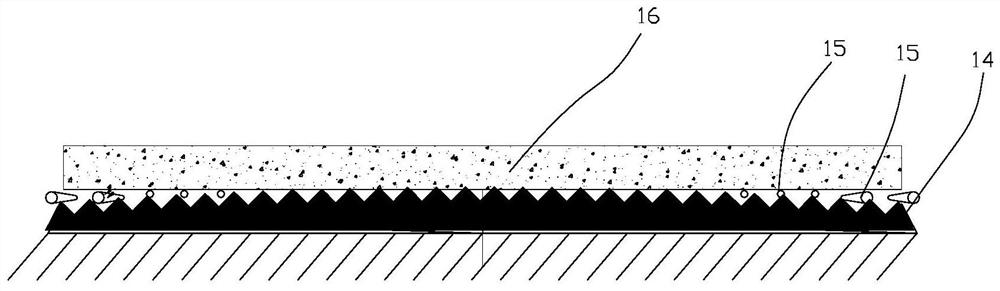

[0022] To solve the above problems, see figure 1 and figure 2 As shown, the embodiment of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com