Waterproof sealing assembly for horizontal through-wall pipeline and leakage detection method of waterproof sealing assembly

A technology of waterproof sealing and detection method, which is applied to pipeline systems, pipes/pipe joints/fittings, pipes, etc., and can solve the problems of inability to detect whether waterproof casings and wall-penetrating pipes are leaking, and inconvenient handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

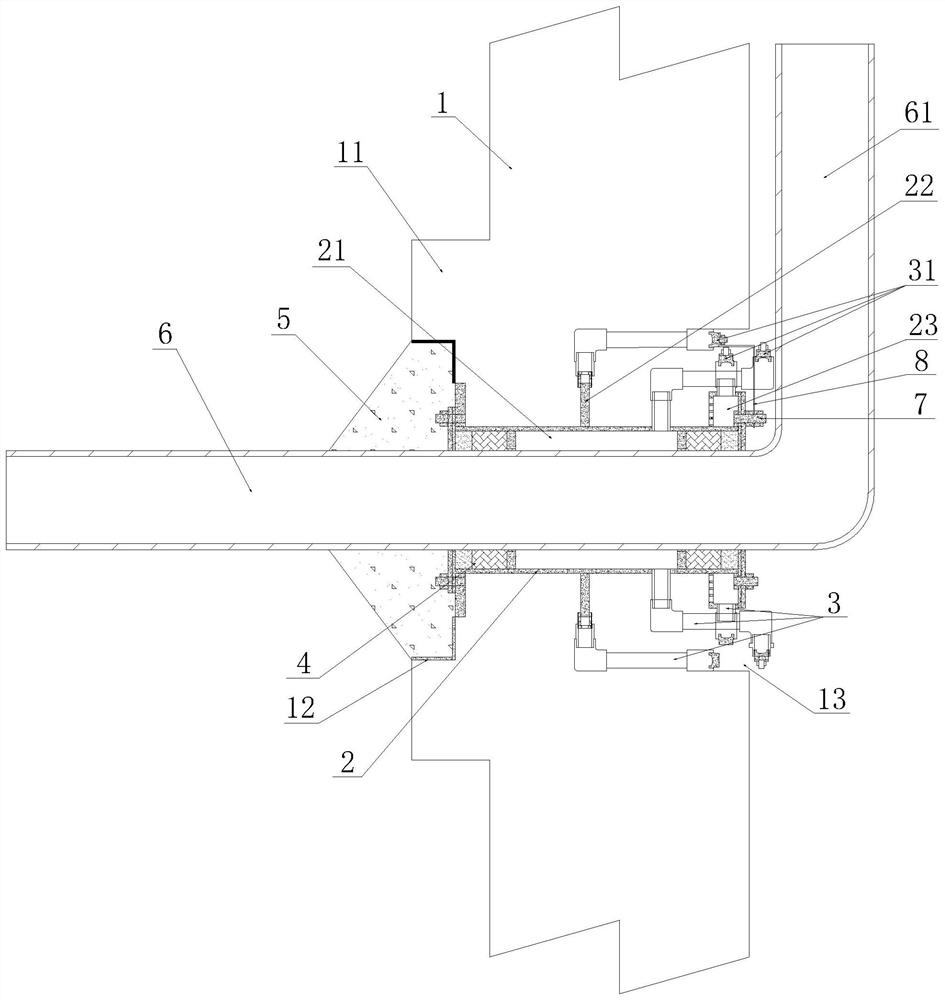

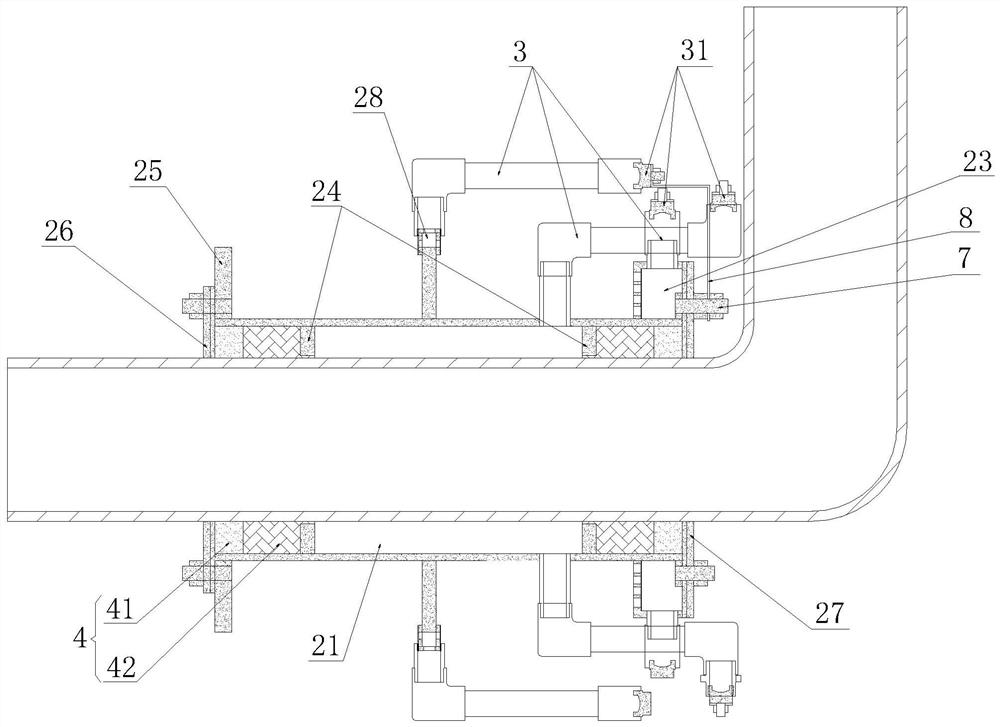

[0027] The technical scheme that the present invention takes can refer to figure 1 and figure 2As shown, a waterproof sealing assembly for a horizontal wall-penetrating pipeline is used to seal the horizontal wall-penetrating pipeline 6 passing through the wall. Ring 22, the waterproof casing 2 is set outside the wall-penetrating pipe 6 located in the wall 1, the inner wall of the waterproof casing 2 is provided with an inner retaining ring 24 near the two ends, and the two ends of the outer wall of the waterproof casing 2 are outwards. An outer retaining ring 25 is provided, and the waterproof casing 2 is near the inner wall surface of the wall body 1 (refer to figure 1 , in this example the figure 1 The wall on the right side is defined as the inner wall) The outer retaining ring 25 is provided with an inner wall wing 27, and the waterproof casing 2 is near the outer wall of the wall 1 (refer to figure 1 , in this example the figure 1 The wall on the left side is define...

Embodiment 2

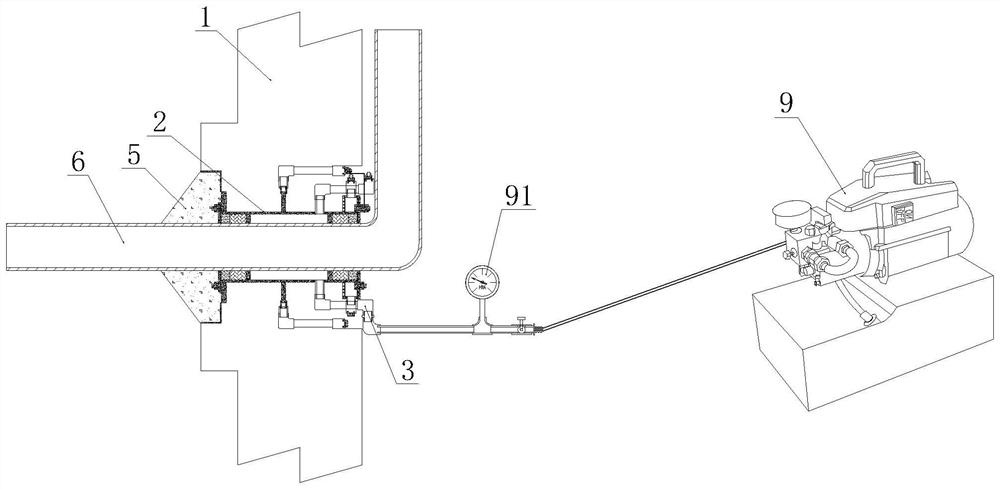

[0029] refer to Figure 1~3 In this embodiment, on the basis of Embodiment 1, an annular water storage tank is provided outside the waterproof casing 2 at the 4 places of the sealing member, and the side of the water storage tank near the inner wall surface of the wall body 1 is open, and the inner wall The wing plate 27 is arranged at the open end of the water storage tank, is closely combined with the water storage tank and forms an airtight water storage chamber 23 in the tank; the outer wall of the water storage chamber 23 is provided with a leak detection tube 3 communicated with the water storage chamber 23 to detect leaks. One end of the pipe 3 is connected to the outer wall of the water storage tank, and the other end is connected to the high-pressure water pump 9 or the grouting pump; If water leakage is judged, disconnect the connection with the high-pressure water pump, connect the leak detection pipe to the grouting pump, and grout the water storage chamber through...

Embodiment 3

[0031] refer to Figure 1~3 In this embodiment, on the basis of Embodiment 2, an annular housing chamber 28 is provided on the outer ring of the water stop ring 22, and a leak detection tube 3 communicating with the housing chamber 28 is provided on the outer ring of the housing chamber 28. One end of the leakage pipe 3 is connected to the outer wall of the accommodation chamber 28, and the other end is connected to the high-pressure water pump 9 or the grouting pump; If it is judged that there is leakage, disconnect the connection with the high-pressure water pump, connect the leak detection pipe to the grouting pump, and grout the chamber through the leak detection pipe to deal with the leakage; if it is judged that there is no leakage, disconnect the connection with the grouting pump There is no need to deal with the connection of the high-pressure water pump, but for the sake of insurance, a grouting pump can also be connected to fill the cavity and the leak detection pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com