Environmentally-friendly efficient drying facility for bioengineering

A technology of biological engineering and drying equipment, applied in the directions of drying solid materials, drying goods processing, drying gas arrangement, etc., can solve the problems of insufficient drying, accumulation into lumps, low efficiency, etc., to reduce operation trouble, reduce trouble, Simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

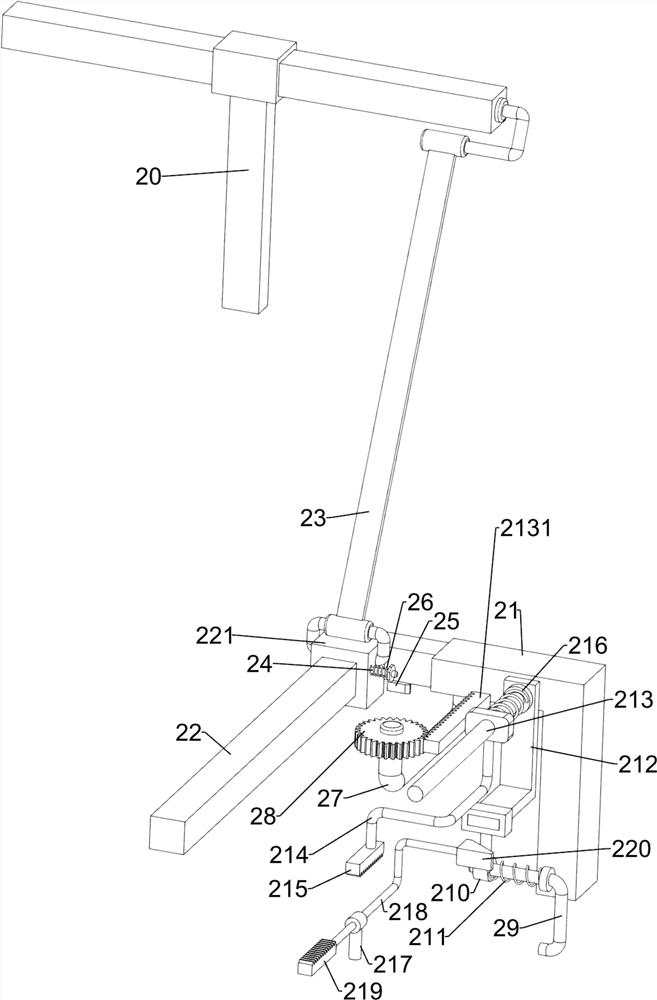

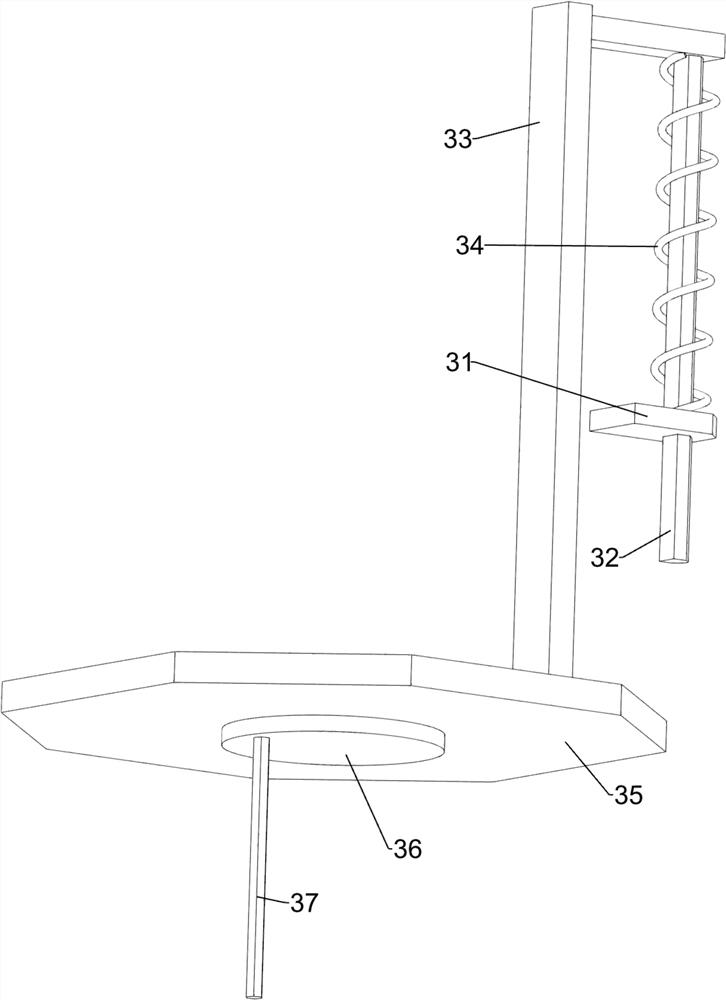

[0030] A kind of environment-friendly high-efficiency drying equipment for bioengineering, such as Figure 1 to Figure 4 As shown, it includes a frame 1, a box body 2, a shaking assembly 3, a material blocking assembly 4 and a heating assembly 5. The upper side of the frame 1 is provided with a box body 2, and the box body 2 is provided with a shaking assembly 3. The box body The upper side of the box body 2 is provided with a blocking assembly 4, and the left side of the box body 2 is provided with a heating assembly 5.

[0031] When it is necessary to dry the bioengineering material, control the stopper component 4 to open, then place the material in the box body 2, then close the stopper component 4, and then control the shaking component 3 to operate, so that the gas in the box body 2 The circulation is faster, and the heating component 5 can also be activated at the same time, thereby increasing the temperature in the box body 2, thereby speeding up the drying of the mate...

Embodiment 2

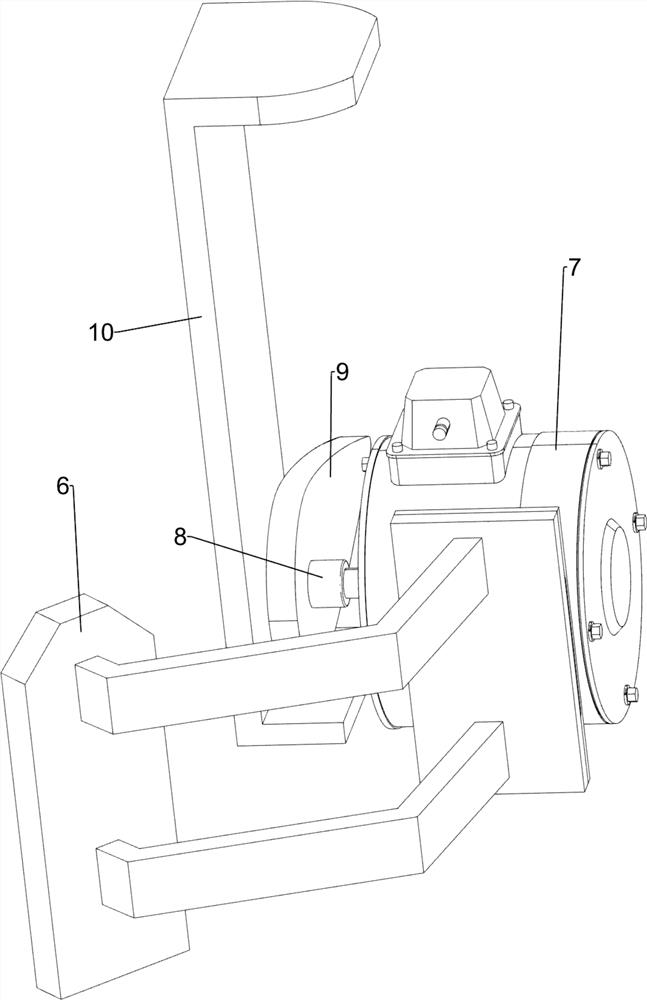

[0039] On the basis of Example 1, such as Figure 5 , Image 6 and Figure 7 As shown, it also includes a second mounting frame 6, a motor 7, a second rotating shaft 8, a cam 9 and a contact frame 10, and the rear side of the box body 2 is fixedly connected with a second mounting frame 6 by bolts, and on the second mounting frame 6 A motor 7 is provided, the output shaft of the motor 7 is connected with a second shaft 8, the second shaft 8 is keyed with a cam 9, the lower side of the first slide bar 32 is welded with a contact frame 10, and the contact frame 10 cooperates with the cam 9 .

[0040] When it is necessary to dry the bioengineering material, start the motor 7, and the motor 7 will drive the second rotating shaft 8 to rotate, thereby causing the cam 9 to rotate. When the cam 9 rotates to contact with the contact frame 10, the contact frame will be 10 moves downwards, thereby causing the first sliding rod 32 to move downwards. When the cam 9 rotates until it is no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com