Liquid storage tank cleaning detection method

A detection method and storage tank technology, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of different speeds of impurities such as rust, difficulty in guaranteeing product quality, and affecting the tank cleaning cycle, etc., to achieve effective preservation The effect of sample composition, avoiding the loss of tank clearing products and waste of manpower and material resources, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

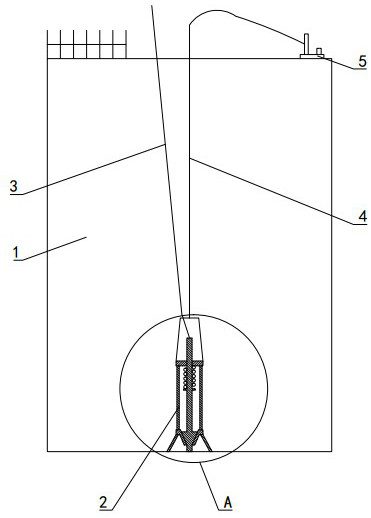

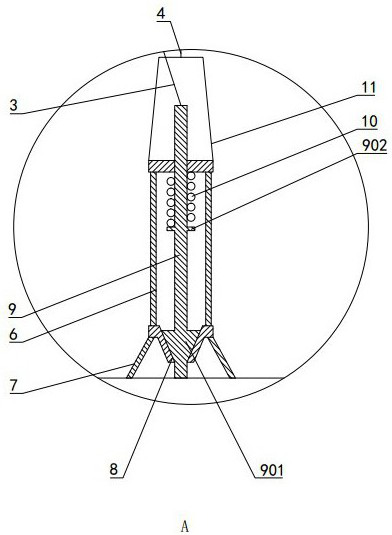

[0030] Figure 1~2 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~2 The present invention will be further described.

[0031] The sampling device includes a sampling cylinder 6 and a valve stem 9 arranged in the sampling cylinder 6. The lower end of the sampling cylinder 6 is provided with a sampling port 8. The spring 10 that closes the sampling port 8 and the valve stem 9 are also connected with the sampling rope 3 . The spring 10 pushes the valve stem 9 to close the sampling port 8, and the sampling rope 3 is connected to the valve stem 9, and drives the valve stem 9 to move up to open the sampling port 8, so that the medium of any depth can be sampled according to the needs, and the sampling is accurate and easy to use. convenient.

[0032] The present invention will be further described below in conjunction with specific embodiments, yet those who are familiar with the art should understand that the detailed description...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com