Yaw angle-based groove type structure surface drag reduction effect prediction method

A technology of structural surface and prediction method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low applicability and robustness, and achieve the effect of improving computing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

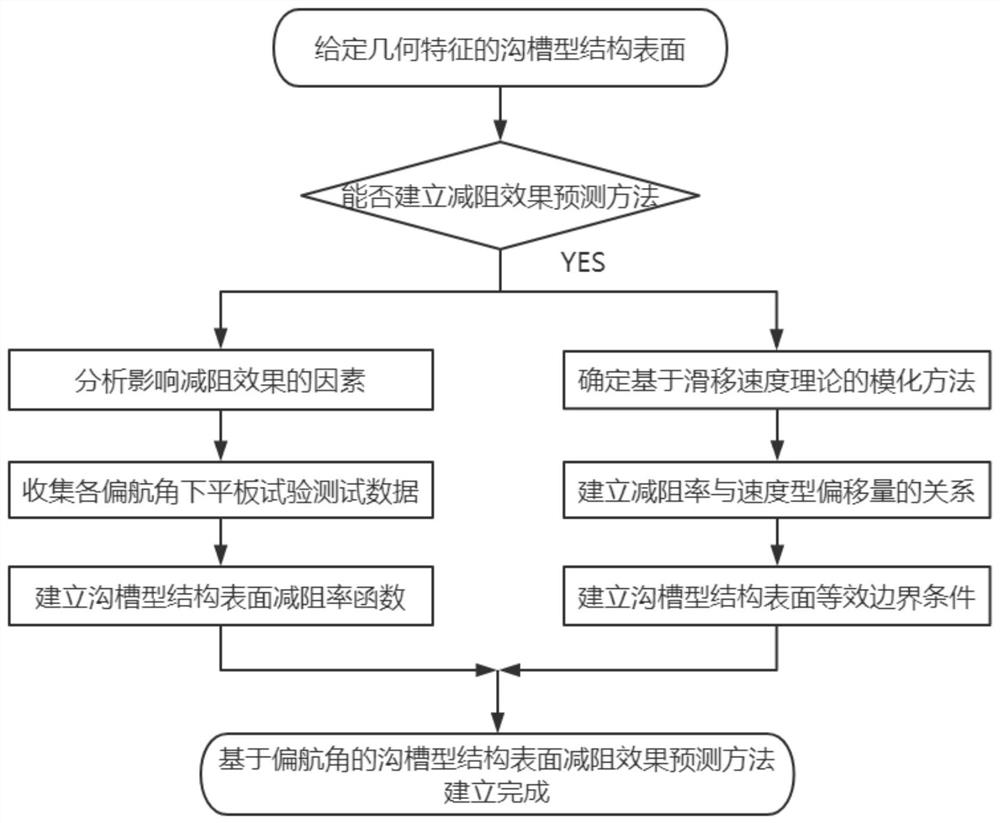

[0058] A method for predicting the surface drag reduction effect of grooved structures based on yaw angle, comprising the following steps:

[0059] S1`: Clarify the flow control mechanism and time-averaged flow characteristics of the grooved structure surface treatment technology.

[0060] In this embodiment, the groove structure is a symmetrical V-shaped groove surface on a micron scale, such as Figure 4 shown. Because its flow control mechanism and time-averaged flow characteristics are consistent with the surface treatment technology of the groove structure, the drag reduction effect can be predicted.

[0061] S2`: Determine the idea of numerical modeling processing.

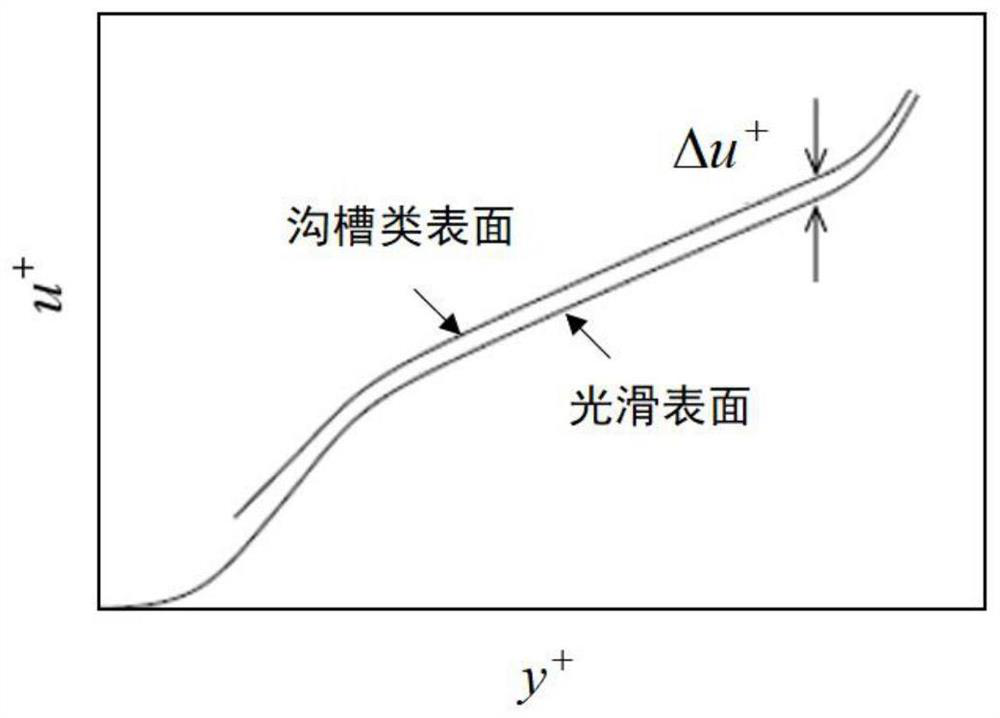

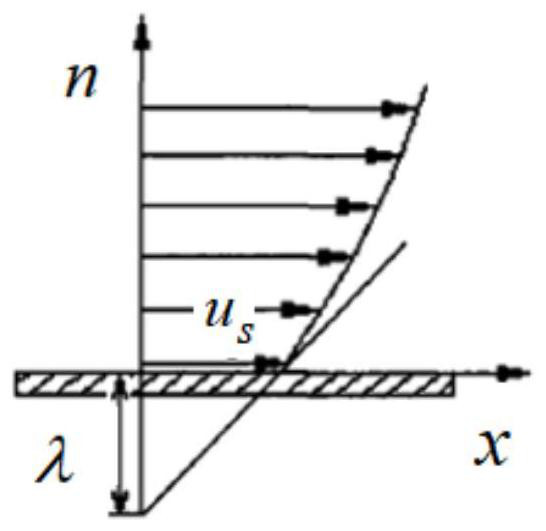

[0062] First, establish the relationship between the drag reduction effect and the influencing factors under the influence of yaw angle;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com